Index – Reznor RPB Unit Installation Manual User Manual

Page 39

Form I-RPB, P/N 131782 R12, Page 39

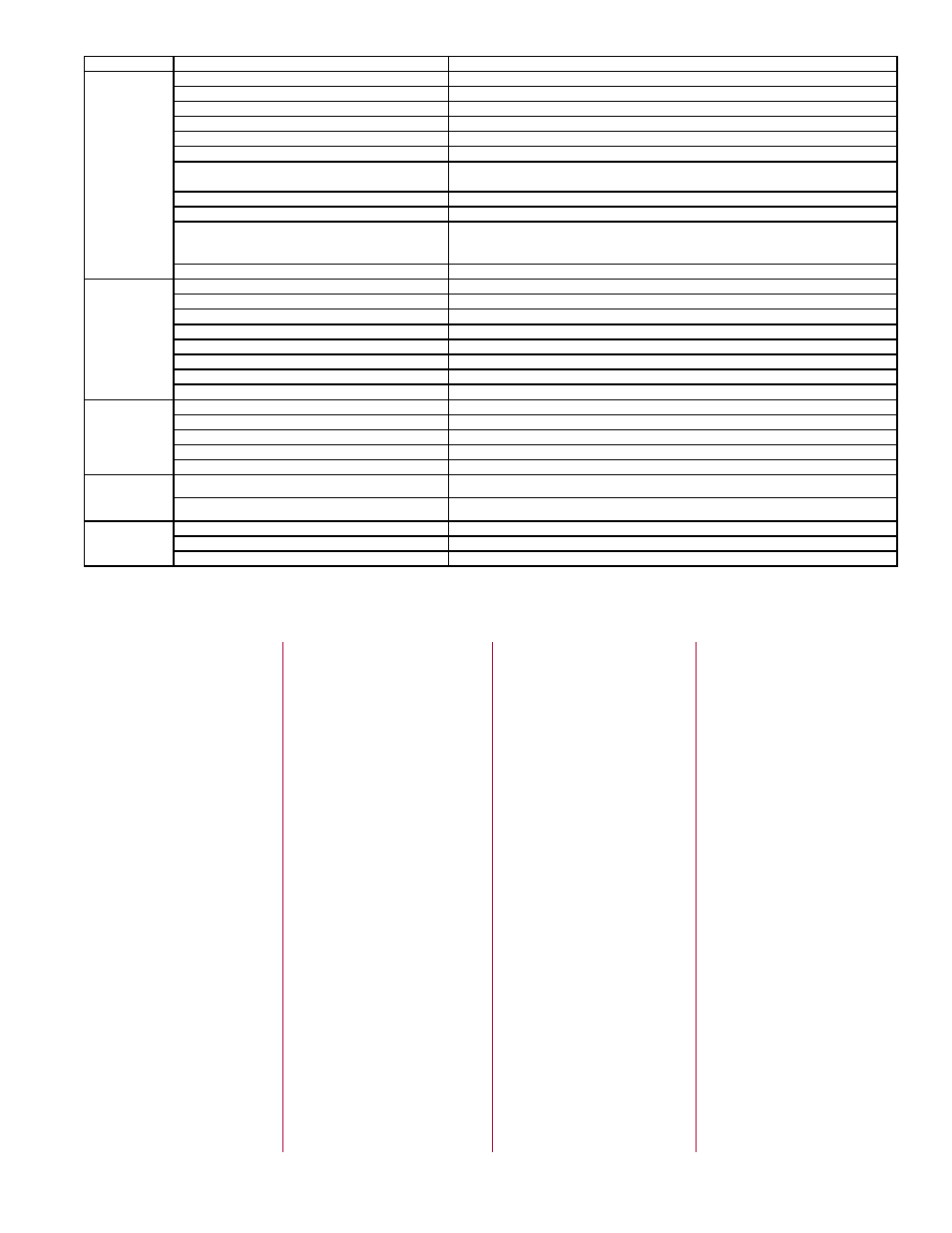

TROUBLE

PROBABLE CAUSE

REMEDY

Pilot lights;

main valve will

not open.

1. Manual valve not open.

1. Open manual valve.

2. Main valve not operating.

2.

a) Defective valve.

a) If 24 volt is measured at valve connections and valve remains closed, replace valve.

b) Loose wire connections.

b) Check and tighten all wiring connections.

3. Ignition control does not power main valve.

3.

a) Loose wire connections.

a) Check and tighten all wiring connections.

b) Flame sensor grounded. (Pilot lights - spark

continues)

b) Be certain flame sensor lead is not grounded or insulation or ceramic is not

cracked. Replace as required.

c) Gas pressure incorrect.

c) Adjust gas pressure. (See Paragraph 6.1.)

d) Cracked ceramic at sensor.

d) Replace sensor.

e) Faulty ignition controller.

e) See Paragraph 8.2. If all checks indicate no other cause, replace ignition controller.

Do not attempt to repair the ignition controller. This device has no field replaceable

parts.

f) Poor microamp signal

f) Adjust pilot regulator

No heat

(Heater

operating.)

1. Dirty filters in blower system.

1. Clean or replace filters.

2. Incorrect manifold pressure or orifices.

2. Check manifold pressure (See Paragraph 6.1).

3. Cycling on limit control.

3. Check air throughput (See Paragraph 6.5).

4. Improper thermostat location or adjustment.

4. See thermostat manufacturer's instructions.

5. Belt slipping on blower

5. Adjust belt tension

6. Fan control improperly wired

6. Connect as per wiring diagram.

7. Defective fan control.

7. Replace fan control.

8. Blower set for too low temperature rise.

8. Slow down blower or increase static pressure.

Motor will not

run

1. Circuit open

1. Check wiring and connections.

2. Fan Control inoperative

2. Replace fan control.

3. Fan control improperly wired

3. Connect as per wiring diagram.

4. Contactor inoperative

4. Replace contactor.

5. Defective motor.

5. Replace motor.

Motor turns on

and off while

operating

1. Motor overload device cycling

1. Check motor load against motor rating place. Replace motor or overload device.

2. 3-phase motor rotating in opposite direction

2. Interchange two legs of supply connections.

Motor cuts out

on overload

1. Improper motor pulley adjustment

1. See instructions on air throughput (See Paragraph 6.5).

2. Improper static pressure on duct system

2. Adjust dampers in duct system.

3. Low voltage

3. Check power supply.

Index

A

Opt High Ambient Limit Control 29

AquaSaver Timed Metering 16

AquaSaver Timer Adjustment 18

B

Belt Tension 22

Blocked Vent Switch 29

Burner Air Adjustment 34

C

Check Installation After Startup 35

Check Installation and Start-Up 34

Cleaning Pilot and Main Burners 37

Cleaning the Heat Exchanger 37, 38

Combustion Air Pressure Switch Setting

with AG39 32

Combustion Air Requirements 3

D

Optional Dampers & Controls 14

Dimensions of Outside Air Hood 11

Discharge Air Sensor 21, 22

E

Electrical Supply & Connections 24

Optional Electronic Modulation 30

Evaporative Cooling Maintenance 18

F

Filter Arrangements 13

Float Valve 16

G

Gas Valve 29, 36

H

Outside Air Hood 11

I

Inlet Air 11

INSTALLATION RECORD 40

L

M

Option AG39 Manifold Arrangement 31

O

Operation of Option AG39 31

P

Pilot and Ignition Systems 33, 34

PRESSURE TESTING SUPPLY

R

Reverse Flow, Limit Control 28

Roof Curb Assembly and Installation 7

S

Supply & Drain Water Connections 15

Supply Air Discharge 20

Combustion air proving switch 29

T

Troubleshooting Evap Cooler 20

Troubleshooting Guides - Opts

Optional Two-Stage Operation 29

U

V

2-Way Valve 16

3-Way Valve 16

Gas Valve 29

Optional Vertical Vent (Opt CC3) 10

Supply Voltage 24

W

Wiring and Service - AG39 32