Clearances to horizontal vent terminal – Reznor UEAS Unit Installation Manual User Manual

Page 19

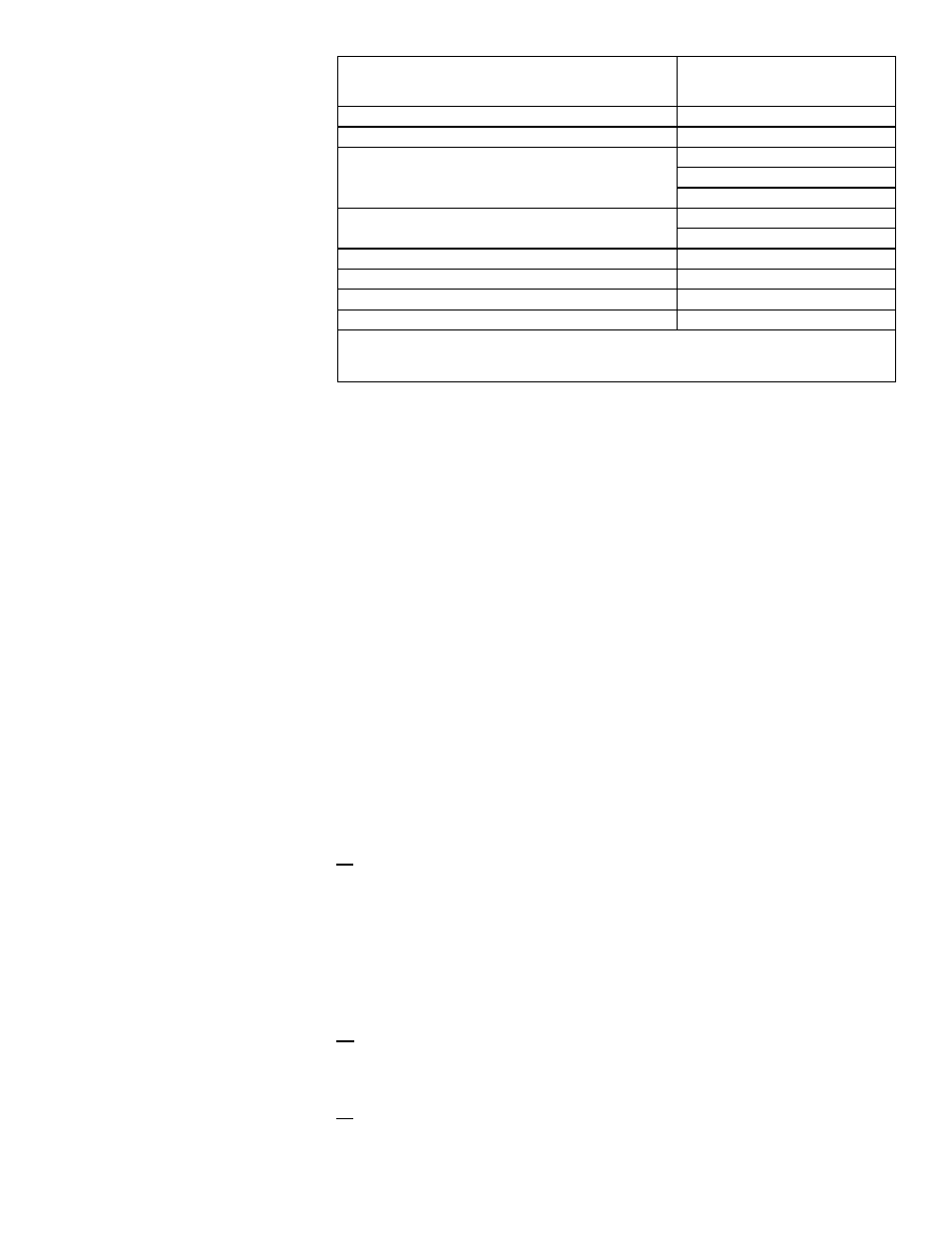

Clearances to Horizontal

Vent Terminal

Structure

Minimum Clearances for Vent

Terminal Location (all directions

unless specified)

Forced air inlet within 10 ft (3.1M)*

3 ft (0.9M) above

Combustion air inlet of another appliance

6 ft (1.8M)

Door, window, or gravity air inlet (any building opening)

4 ft (1.2M) horizontally

4 ft (1.2M) below

1 ft (305mm) above

Electric meter, gas meter ** and relief equipment

U.S. - 4 ft (1.2M) horizontally

Canada - 6 ft (1.8M)

Gas regulator **

3 ft (0.9M) horizontally

Adjoining building or parapet

6 ft (1.8M)

Adjacent public walkways

7 ft (2.1M) above

Grade (ground level)

3 ft (0.9M) above***

*Does not apply to the inlet of a direct vent appliance. **Do not terminate the vent directly above

a gas meter or service regulator. *** Consider local snow depth conditions. The vent must be at

least 6” (152mm) higher than anticipated snow depth.

2. Install the vent pipe and combustion air pipe runs (from the heater to

near the location selected through the wall).

• Use the type of pipe specified in Paragraph 7.2.1.1, page 12.

• Comply with the requirements in Paragraph 7.2.1.2 and 7.2.1.3, pages

12-14, when attaching pipes to the heater and installing the condensate drain

connection in the vent.

• Overall vent length must comply with the table in Paragraph 7.2.1.4, page 14.

• Make all joints according to the instructions in Paragraph 7.2.1.6, pages 14-15.

Extend the runs close to the wall location selected in Step 1 above. Provide

1/4” per foot (6mm per 305mm) downward pitch of the vent pipe toward the

heater for condensate to drain (

NOTE: The vent pipe will extend through the

wall after the concentric adapter box is installed. The indoor combustion air

pipe will end at the concentric adapter box.)

• Support pipes as required in Paragraph 7.2.1.7, pages 15-16.

3. Prepare a 9” diameter clearance hole through the outside wall for the 8”

diameter combustion air pipe.

Outside wall construction thickness should be 1” (25mm) minimum and 48”

(1219mm) maximum. Position the box against the wall. Being sure that the loca-

tion and box orientation are correct, mark the location where the combustion air

pipe will extend through the wall. Cut a 9” diameter hole so that the 8” pipe will be

centered through the 9” opening.

4. Prepare the concentric adapter box.

4a) Determine the length of the 8” diameter combustion air pipe and attach

it to the box.

Comply with the requirements in

FIGURE 16. Determine the length of the pipe

by measuring the wall thickness,

plus 4 to 16” (102-406 mm) beyond the wall,

minus the width of the pipe crimp which will be cut off.

So that the 8” inlet air guard will fit properly, cut the crimp off the end of the com-

bustion air pipe. Turn the combustion air pipe so that the seam will be toward the

top side of the box and slide it on the collar. Attach the combustion air pipe to the

collar with sheetmetal screws. Seal the joint and seam with sealant or tape.

4b) Drill a drain hole. On the bottom side of the pipe, mark a location that will be

outside between the end of pipe and the building (about 2/3 of the distance from

the end of the pipe to the edge of the building) when the box is installed. Drill a

1/2” diameter drain hole in the pipe at that location.

4c) Attach the inlet air guard. Position the inlet air ring guard over the end of

the combustion air pipe. See

FIGURE 16. Attach the guard to the inlet air pipe

with the four 1/2” long screws provided.

Form I-UEAS, P/N 221232 R13, Page 19