Enthalpy switch (fig. 23) – Carrier 39L User Manual

Page 43

NOTE: This sensor uses a resistance temperature device (RTD)

element. Polarity is not a consideration.

When space does not allow working inside the duct, mount

as follows (Fig. 22):

1. Open a duct penetration on the opposite side of the sen-

sor junction box.

2. Wrap the element around a

3

⁄

4

-in. PVC pipe, cut holes

near the center of the duct on both sides and feed the pipe

with sensor element through the hole.

3. Secure the seal around the PVC pipe.

NOTE: If local codes do not permit the use of PVC, use

EMT instead.

Refer to Field Wiring Connections section, page 52 for

wiring instructions and details. See Table 5 for RTD resis-

tance vs temperature values.

Table 5 — RTD Resistance vs Temperature Values

for Mixed-Air Temperature Sensor

RESISTANCE

(Ohms)

TEMP

(F)

RESISTANCE

(Ohms)

TEMP

(F)

RESISTANCE

(Ohms)

TEMP

(F)

693

−40

940

50

1223

140

719

−30

970

60

1257

150

745

−20

1000

70

1290

160

772

−10

1031

80

1325

170

799

0

1062

90

1360

180

827

10

1093

100

1395

190

854

20

1125

110

1430

200

883

30

1157

120

—

—

912

40

1190

130

—

—

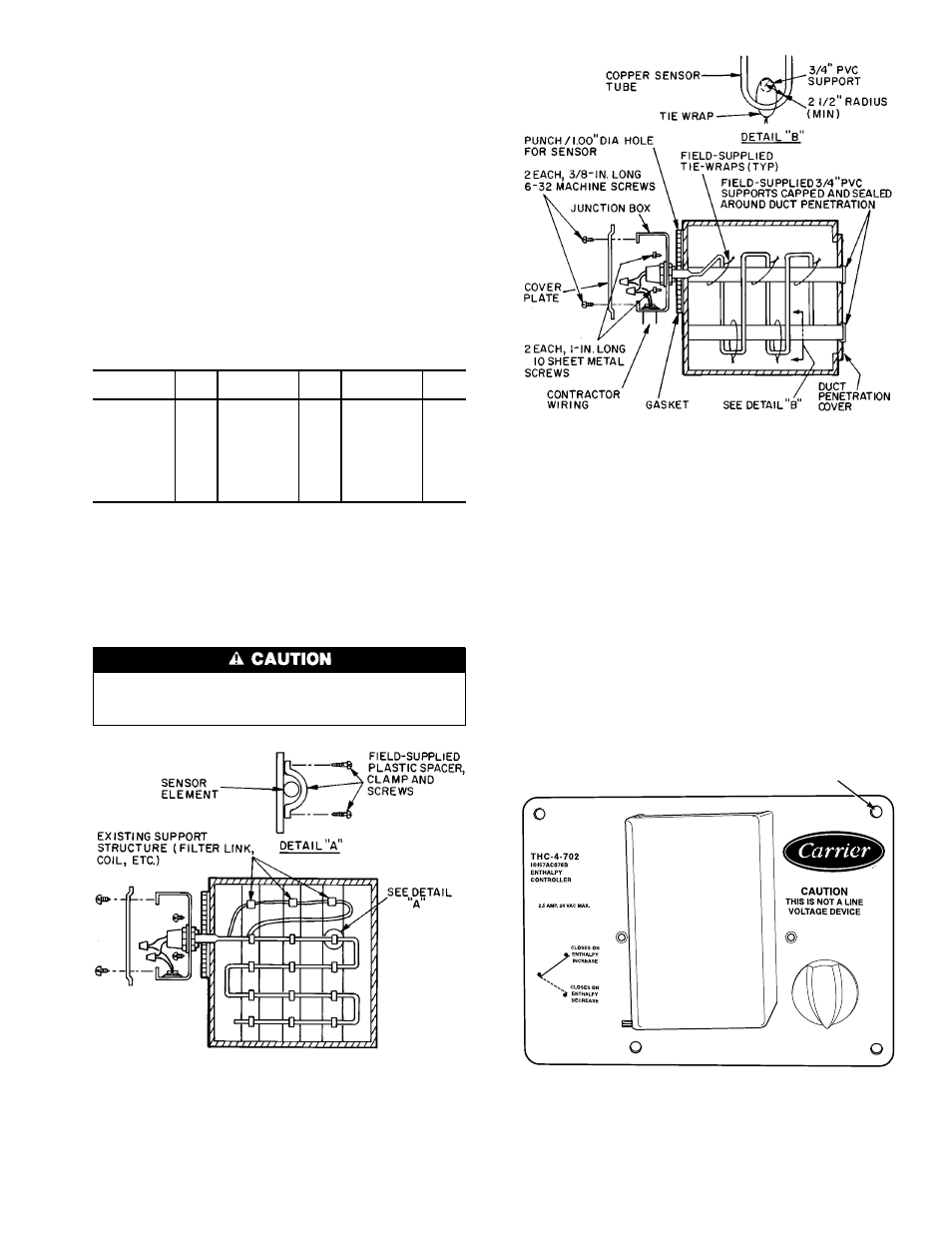

Enthalpy Switch (Fig. 23) —

The enthalpy switch and

mounting template are located in a box shipped inside the

fan section.

The enthalpy switch is normally mounted in a horizontal

position with the sensing element exposed to freely circu-

lating outdoor air.

DO NOT install enthalpy switch in locations where ex-

cessive moisture, corrosive fumes, and/or vibration are

present.

Mount the switch as follows:

1. Position mounting template on duct. Remove adhesive

backing and press template onto outside air duct.

2. Drill four

1

⁄

8

-in. mounting holes as indicated on the

template.

3. Cut out center portion of duct as outlined on template.

4. Mount controller to duct using screws provided.

If no outside air duct is present, mount the enthalpy switch

on a field-supplied and installed plate upstream of the out-

side air damper.

Connect the red and blue wires of the enthalpy switch to

the PIC control box terminals. Refer to Field Wiring

Connections section, page 52 for further details.

CONTROL RANGES — See Fig. 24 for control settings and

intermediate settings.

Fig. 21 — Mixed-Air Temperature Sensor

(P/N HH79NZ021) Installation

Fig. 22 — Alternate Mixed-Air Temperature

Sensor Installation

A

B

C

D

Y

E

L

R

E

D

B

L

U

MOUNTING HOLES

Fig. 23 — Enthalpy Switch (P/N HH57AC076)

43