Outdoor-air temperature sensor (fig. 19), Mixed-air temperature sensor – Carrier 39L User Manual

Page 42

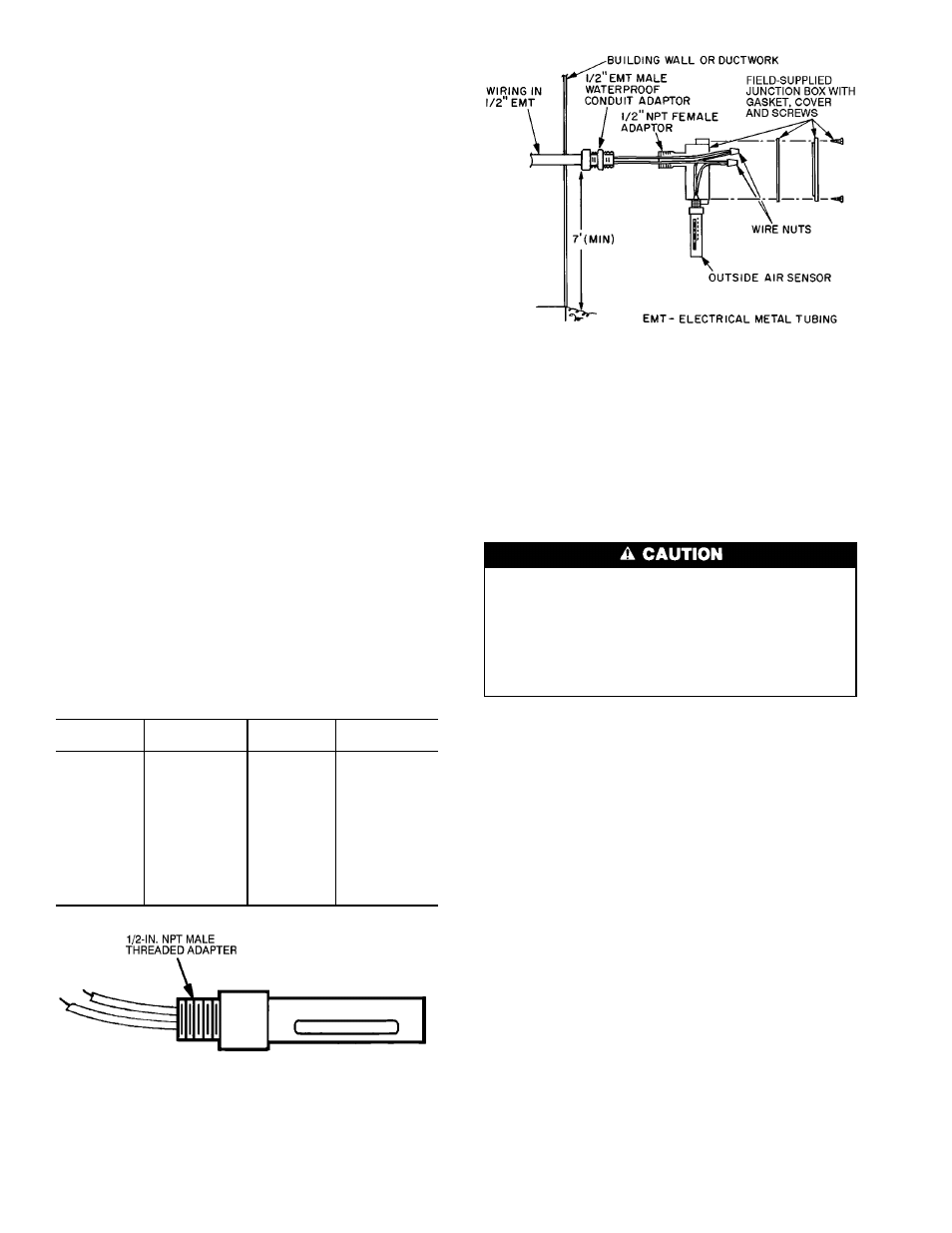

Outdoor-Air Temperature Sensor (Fig. 19) —

The outdoor-air temperature (OAT) sensor is shipped inside

the fan section. The OAT sensor continuously monitors the

temperature of the air outside the building. The integral shield

prevents ice formation on the sensor conductors. A field-

supplied conduit junction box is required for installation. See

Fig. 20.

Position the OAT sensor so that it accurately senses only

the outdoor-air temperature. The sensor must be located up-

stream from outside air dampers and located where it is un-

affected by interior and duct temperatures. During the unoc-

cupied (fan off) period the sensor’s location should have a

minimal effect on its readings.

Do not mount the sensor in direct sunlight. Inaccurate read-

ings may result. It may be necessary to field-fabricate a shield

to protect the sensor from direct sunlight.

Do not mount the sensor near the exhaust from air-

handling units or compressors, or near leakage drafts of in-

door air, or near shrubbery or trees. Inaccurate readings may

result. Do not mount under direct water runoff. Water may

freeze around the sensor in winter and produce a false

reading.

If sensor wire is shielded, strip back the sensor shield and

tape it to prevent contact.

Position the sensor with the slotted end pointed

downward.

The field-supplied junction box housing must be threaded

to screw onto a male

1

⁄

2

-in. NPT electrical metal tubing (EMT)

conduit adaptor. The assembled box and sensor must be mounted

parallel to the building wall. See Fig. 20. The sensor can

also be installed on a roof or other location.

For distances up to 500 ft, use 2-conductor 20 AWG cable

to connect the sensor to the PIC terminals. Refer to the Field

Wiring Connections section, page 52 for further wiring in-

structions. See Table 4 for thermistor resistance according to

temperature value.

Table 4 — Thermistor Resistance vs

Temperature Values for Outdoor-Air

Temperature Sensor

RESISTANCE

(Ohms)

TEMPERATURE

(F)

RESISTANCE

(Ohms)

TEMPERATURE

(F)

168,250

−40

5,000.0

77

121,350

−31

4,028.5

86

88,500

−22

3,265.0

95

65,200

−13

2,663.3

104

48,535

−4

2,185.0

113

36,476

5

1,801.5

122

27,665

14

1,493.0

131

21,165

23

1,244.0

140

16,325

32

1,041.5

149

12,695

41

876.0

158

9,950

50

739.5

167

6,245

68

627.5

176

Mixed-Air Temperature Sensor —

The optional

mixed-air temperature sensor (MAT) is factory wired and

installed on all units with a factory-installed mixing box (MXB),

filter mixing box (FMB), or air blender (AMX). On units

without an AMX, MXB, or FMB, the optional MAT is pack-

aged and shipped inside the fan section for field installation.

The field-installed MAT should be mounted downstream

of the return air duct and filters, but as close as possible to

the 39L or 39NX unit.

AVOID repeated bending of copper tubing, as this will

place stress on the sensor element and lead to eventual

breakage.

DO NOT fold or crimp copper tubing.

USE CARE in forming and securing the element.

STRIP back and tape the shield in order to prevent

contact.

Mount field-installed MAT as follows (Fig. 21):

1. Punch a 1-in. diameter hole in the duct and feed the sen-

sor element through the hole. Mount the utility box on

the outside of the duct.

2. Bend the copper tubing surrounding the sensor element

to conform to the area of the duct. Do not bend it to less

than 2

1

⁄

2

in. diameter on any turn. The sensor element

should be evenly distributed over the entire cross sec-

tional area of the duct.

Existing support structures may be used for the sensor

element, as long as there is no metal-to-metal contact with

the copper tubing, and the mounting does not interfere

with other functions.

3. Use a field-supplied plastic spacer, clamp, and screws to

secure the sensor in the airstream. See Detail A,

Fig. 21.

4. Using 2-conductor 20 AWG plenum-rated cable, connect

the sensor to the PIC control box terminals.

Fig. 19 — Outdoor-Air Temperature Sensor

(P/N HH79NZ023)

Fig. 20 — Outdoor-Air Temperature

Sensor Installation

42