Electronic valve actuator field test, Control loop checkout – Carrier 39L User Manual

Page 108

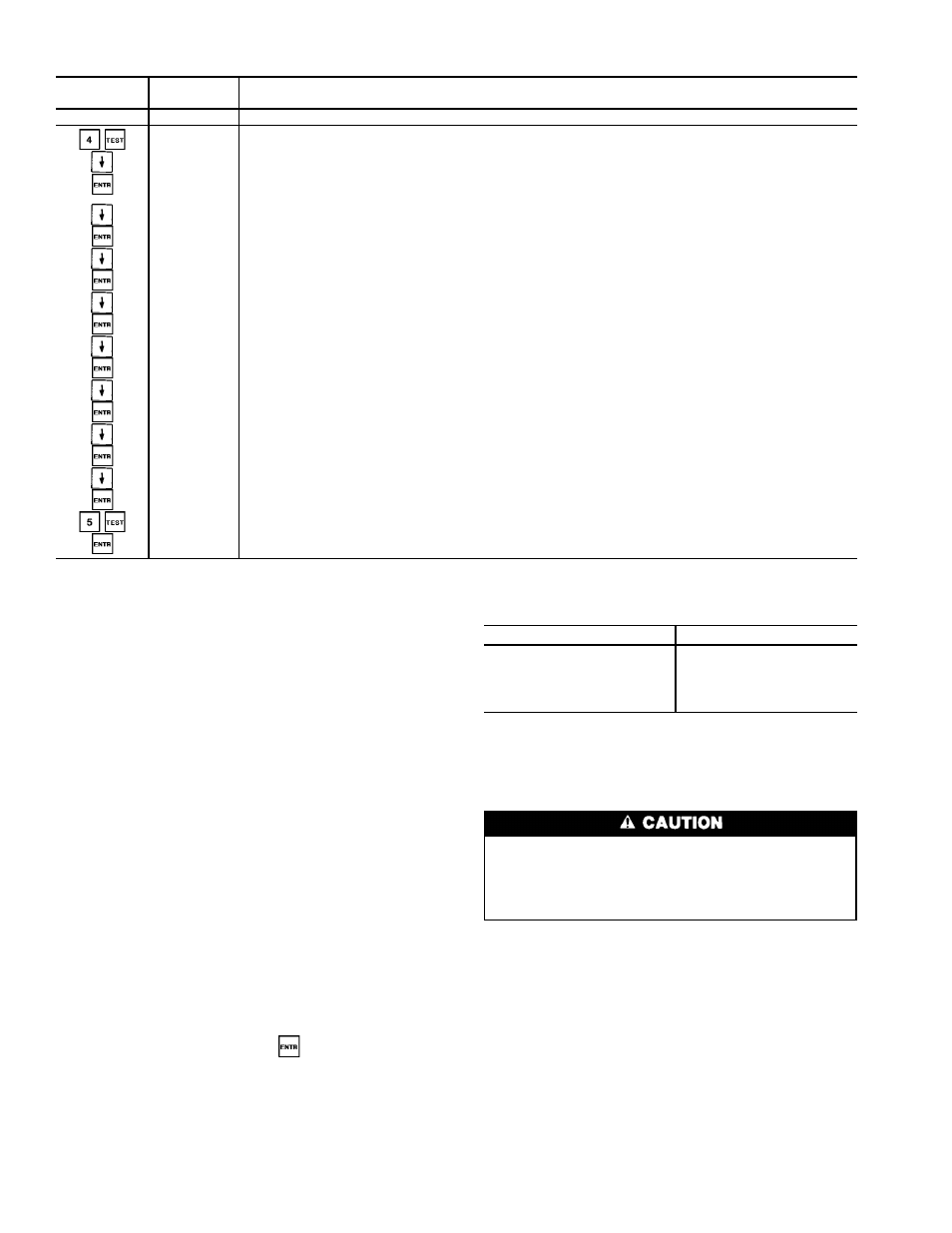

Table 22 — Direct Expansion (DX) Cooling Test

KEYBOARD

ENTRY

DISPLAY

RESPONSE

COMMENTS/ACTION

NOTE: Only the configured number of stages are tested and appear on the display.

DX COOL

Entering field test DX cooling coil. (Set the HOA switch to AUTO.)

DXS1 X

STG1 TST

The fan starts. If fan has IGVs, the IGVs open to 30%. After an 11-second delay, the 1st stage of DX cooling

is turned ON.

DXS2 X

The 1st stage of DX cooling is turned OFF.

STG2 TST

After a 2-second delay, the 2nd stage of DX cooling is turned ON.

DXS3 X

The 2nd stage of DX cooling is turned OFF.

STG3 TST

After a 2-second delay, the 3rd stage of DX cooling is turned ON.

DXS4 X

The 3rd stage of DX cooling is turned OFF.

STG4 TST

After a 2-second delay, the 4th stage of DX cooling is turned ON

DXS5 X

The 4th stage of DX cooling is turned OFF.

STG5 TST

After a 2-second delay, the 5th stage of DX cooling is turned ON.

DXS6 X

The 5th stage of DX cooling is turned OFF.

STG6 TST

After a 2-second delay, the 6th stage of DX cooling is turned ON.

DXS7 X

The 6th stage of DX cooling is turned OFF.

STG7 TST

After a 2-second delay, the 7th stage of DX cooling is turned ON.

DXS8 X

The 7th stage of DX cooling is turned OFF.

STG8 TST

After a 2-second delay, the 8th stage of DX cooling is turned ON.

EXIT TST

The fan and preceding DX cooling stage shut OFF.

TST CMPL

Test is complete. The unit is back under automatic control.

Electronic Valve Actuator Field Test —

The elec-

trically operated valve actuators supplied with

1

⁄

2

-in. to

1

1

⁄

4

-in. valve assemblies are a hydraulic, linear-piston type.

The actuators supplied with the 1

1

⁄

2

-in. to 3-in. valve assem-

blies are an electro-mechanical type. Both types of actuators

contain a spring as part of the valve assembly. The spring

returns the stem to its normal position whenever there is a

loss of power or signal. Both actuators contain an internal

solid-state drive which accepts a proportional 4 to 20 mA

signal generated by the controller.

An increase in signal proportionally extends the actuator

shaft and pushes the valve stem down. A decrease in signal

retracts the actuator shaft and lifts the valve stem up. Valve

construction determines normal valve flow, either stem-up

open, or stem-up closed. On 3-way mixing valves, stem-up

allows flow from port B to port AB.

Perform field test for actuator as follows:

1. Verify actuator is powered by 24 vac at the WHITE/

BLUE and BLACK actuator wires.

2. Use a digital milliamp meter to verify the mA signal and

proper polarity at the input signal leads,

ϩRED and

−GREEN. A digital volt meter with a minimum of 2-place

accuracy may be used to determine signal value, see

Table 23.

3. Enter the heating coil valve or cooling coil valve Quick

Test, retract the actuator shaft and completely lift valve

stem.

4. While still in Quick Test, press

. The actuator shaft

should extend completely, pushing valve stem down. Exit

Quick Test procedure.

Table 23 — Digital DC Volt Meter vs

DC Milliamp Meter

DC MILLIAMPS

DC VOLTAGE

4

.33

8

.57

12

.99

16

1.32

20

1.65

NOTE: The internal solid-state drives of the factory-supplied elec-

tronic actuators impose a 82.5 ohm impedance to the signal current

loop. A proportional voltage, ranging from 0.33 vdc at 4 mA to to 1.65 vdc

at 20 mA will be present.

CONTROL LOOP CHECKOUT

Checkout and adjustment of control loops should only

be performed by certified Carrier Comfort Network tech-

nicians. The following checkout procedure is offered as

a guide and presumes the user has obtained basic knowl-

edge of controls through CCN training.

To Check Operation of Analog Outputs —

The

control algorithms of the 39L and 39NX use the master/

submaster loop concept. The master loop monitors the mas-

ter sensor (the sensor which tries to maintain the desired set

point), and calculates the submaster reference required to do

so. The submaster loop monitors the submaster sensor and

controls the output to the controlled device. These algo-

rithms require a number of gain values to function properly.

The 39L and 39NX come with preset default values. How-

ever, it may be necessary to adjust several of these values to

achieve stable control. These values are submaster loop gain

(SMG), submaster loop center value (SCV), master loop pro-

portional gain (MPG) and, in some cases, master loop in-

tegral gain (MIG).

108