Unit troubleshooting – Carrier 39L User Manual

Page 113

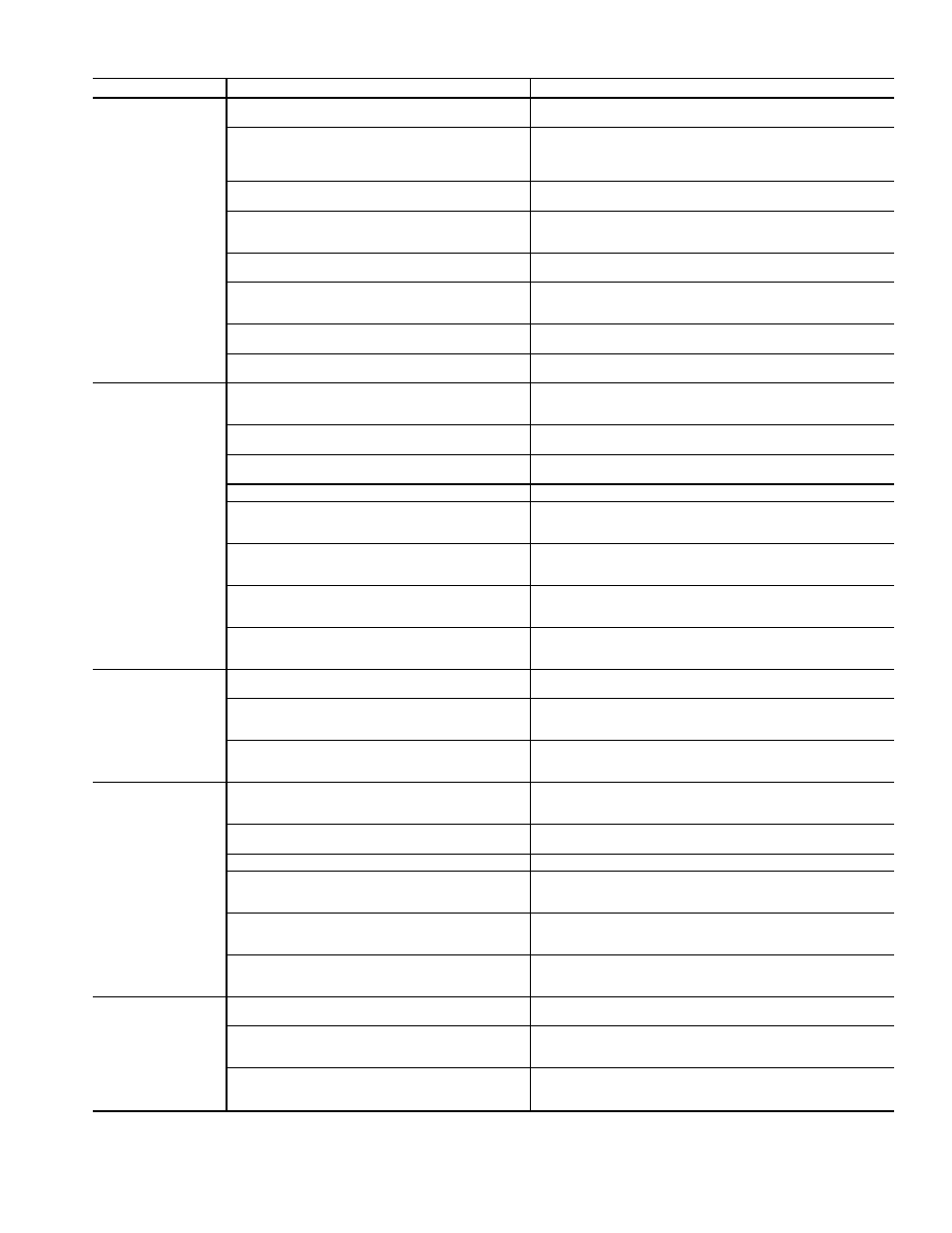

UNIT TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Unit does not run

PIC control is OFF

Check for correct power or blown fuses (F2).

Correct any deficiencies.

Faulty connections

Check LEDs on control module (PSIO). If LED is not solidly

illuminated, check for loose connections. If all wires and

connectors are secure, replace PSIO module as described

on page 112.

PIC control has incorrect time

Verify control shows correct time. If incorrect, enter correct

time.

Supply fan HOA switch in OFF position

Safety controls are tripped

Verify HOA switch is in the AUTO position.

Check low-temperature thermostat and high-pressure switch

(VAV units only). Reset switches if necessary.

PIC control left in Quick Test

(Display shows Mode 38)

Using the local interface device, exit Quick Test.

Press 5 TEST, and then ENTR to exit.

Unit is configured for and is currently

in Demand Limit Mode (CV units only)

Verify that unit should be in the Demand Limit mode. If not,

cycle power to PIC to release unit from Demand Limit

mode.

Unit is in Smoke Evacuation or Fire Shut-

down mode (Display shows 35 or 37)

Verify that unit should be in one of these modes. If not,

check for shorted input on Fire Shutdown or Evacuation.

Minimum inverter set point too low

(VAV units only)

Adjust minimum to 20% at 4 mA signal and 100% at 20 mA

signal.

No heat

No fan status

Check status of SFS (4 STAT). If SFS is OFF, check supply

fan status switch for proper operation. Switch must be ON

for heat coil to function properly.

Heat coil valve (HCV) is forced closed

Check status of HCV (5 STAT). If HCV is forced, remove

force and check operation.

NO hot water or steam available,

no power if electric heat

Check source and correct any problems found.

Electric heater safety tripped

Reset heater safety. Check for proper operation.

No power to valve

Check for blown fuse (F6). Replace if necessary. If fuse

is intact, check for proper connections. Check transformer

output.

No power to electric heater control

Check for blown fuse (F5). Replace if necessary. If fuse

is intact, check for proper connections. Check transformer

output.

Incorrect reading from space temperature sensor,

supply-air temperature sensor, or return-air

temperature sensor (VAV units)

Check status of sensor readings for accuracy.

Replace sensor if defective.

Configuration error

Check configuration for proper heating set point and

Submaster Gain (SMG). An improper SMG can cause the

heating valve to be held closed.

Overheating

Heat coil valve (HCV) is forced open

Check status of HCV (5 STAT). If HCV is forced, remove

force and check operation.

Incorrect reading from space temperature sensor,

supply-air temperature sensor, or return-air

temperature sensor (VAV units)

Check status of sensor readings for accuracy. Replace

sensor if defective.

Configuration error

Check configuration for proper heating set point and

Submaster Gain (SMG). An improper SMG can cause the

heating valve to be held open.

No cooling

No fan status

Check status of SFS (4 STAT). If status is OFF, check

switch for proper operation. Supply fan status switch must

be ON for cooling coil to function properly.

Cooling coil valve (CCV) is forced closed

Check status of CCV (5 STAT). If CCV is forced, remove

force and check operation.

No chilled water available

Check source of chilled water. Correct any problems found.

No power to cooling coil valve

Check for blown fuse (F3). Replace if necessary. If fuse

is intact, check for proper connections. Check transformer

output.

Incorrect reading from space temperature sensor,

supply-air temperature sensor, or return-air

temperature sensor (VAV units)

Check status of sensor readings for accuracy. Replace

sensor if defective.

Configuration error

Check configuration for proper cooling set point and

Submaster Gain (SMG). An improper SMG can cause the

CCV to be held closed.

Overcooling

Cooling coil valve (CCV) is forced open

Check status of CCV (5 STAT). If CCV is forced, remove

force and check operation.

Incorrect reading from space temperature sensor,

supply-air temperature sensor, or return-air

temperature sensor (VAV units)

Check status of sensor readings for accuracy. Replace

sensor if defective.

Configuration error

Check configuration for proper cooling set point and

Submaster Gain (SMG). An improper SMG can cause the

CCV to be held open.

LEGEND

CV

— Constant Volume

VAV — Variable Air Volume

113