Carrier 39L User Manual

Page 38

Variable-Frequency Drives —

The input signal for

the inverter must be 4 to 20 mA. Use a 2-conductor

20 AWG (American Wire Gage) cable (single twisted pair,

unshielded) to connect the input of the inverter to the output

of the PIC control terminals. See Fig. 8.

Wire the inverter so that if it is placed in the manual or

bypass mode the low temperature thermostat and the high-

pressure switch (if supplied) are still in the motor control

circuit to protect the unit.

Adjust the minimum inverter speed to provide at least 10%

airflow when inlet guide vanes are at 0% (4 mA) and maxi-

mum design airflow when inlet guide vanes are at 100%

(20 mA). Use the local interface device to verify that the

supply fan status (

) shows the fan is ON and that the

supply fan is operating at the lowest airflow adjustment. In-

crease inverter minimum speed as required. For additional

information, see the Quick Test section on page 103.

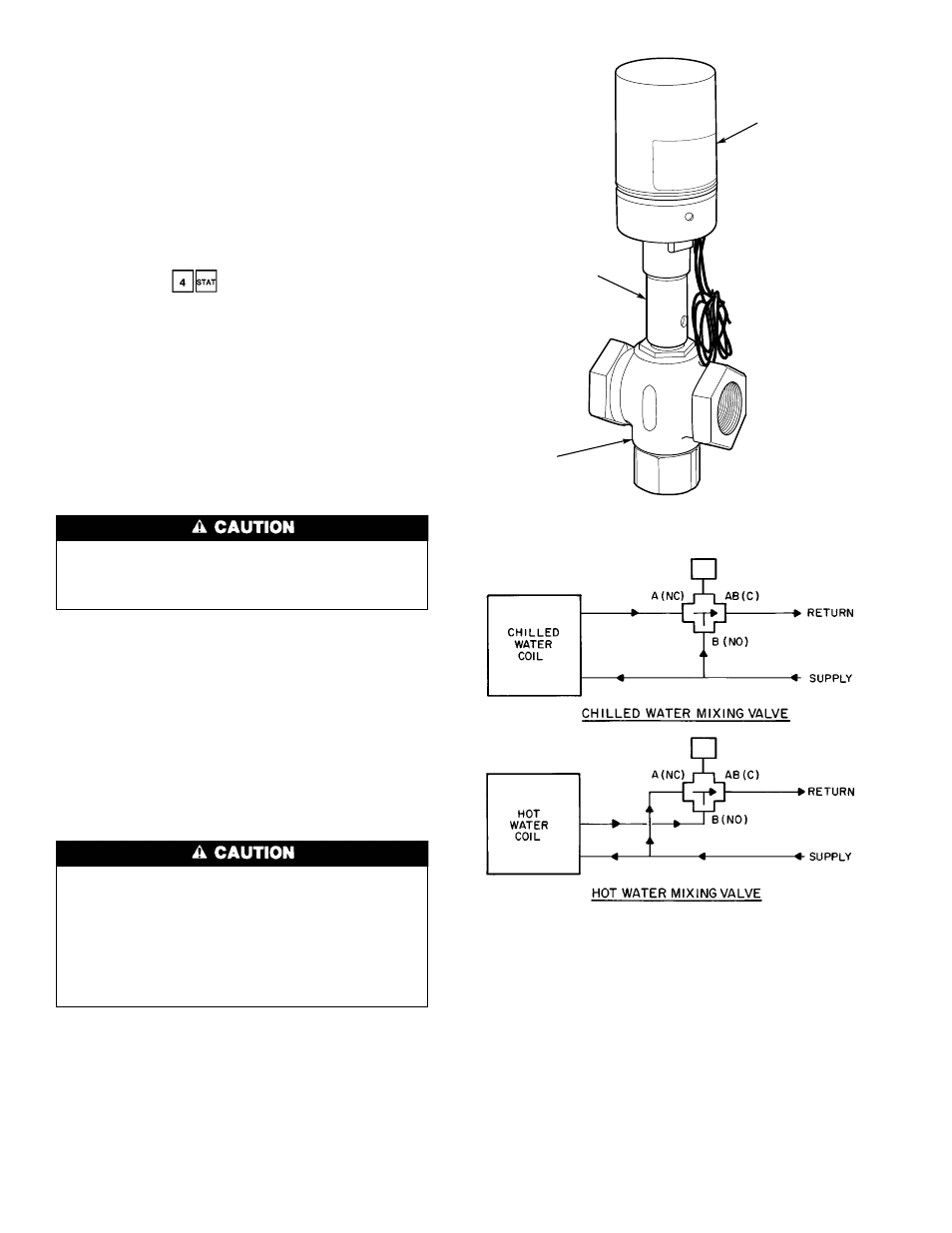

Water Valve Assemblies —

Water valve assemblies

(Fig. 13) are shipped inside the fan section for field instal-

lation. All valve assemblies have electrically powered ac-

tuators. Each actuator has an external junction box for field

wiring. The junction box contains 24 vac power wires (WHITE/

BLUE, BLACK) and 4 to 20 mA signal wires (

ϩRED,

−GREEN). The actuators operate the valve through a linear

stroke; if power is lost, a return spring reverses the stroke

and returns the valve stem to the normal position.

To prevent electric shock and equipment damage, dis-

connect the power to the control box before installing

valve assemblies. Turn power switch located on control

box door to OFF.

On installations where valve mounting space is limited,

use unions to couple valve assemblies to water lines. If unions

do not provide sufficient clearance, refer to the Valve

Troubleshooting section, page 109.

On chilled water applications or hot water applications with

1

1

⁄

2

to 3-in. valves, the valve actuators can be mounted in

any position above the centerline of the valve body. For steam

applications or hot water applications with

1

⁄

2

to 1

1

⁄

4

-in. valves

that have actuators and high-temperature linkage exten-

sions, mount the actuator above the centerline of the valve

body and 45 degrees from vertical. This position helps to

prevent actuator exposure to direct heat convection.

DO NOT install valve assembly where excessive mois-

ture, corrosive fumes, and/or vibration are present.

INSTALL all 2-way valve assemblies so that they close

against system flow. An arrow on the valve body indi-

cates the proper flow direction.

ALWAYS install 3-way mixing valve with 2 inlet flows

and one outlet. Normal flow will be from port B to port

AB with stem up. See Fig. 14.

ACTUATOR LINKAGE

VALVE BODY

VALVE ACTUATOR

Fig. 13 — Valve Assembly (Typical)

Fig. 14 — Three-Way Mixing Valve — Normal Flow,

Typical Piping

38