Valve troubleshooting general, In. through 1, In. electric hot water/ steam valve assemblies – Carrier 39L User Manual

Page 109

To verify or adjust submaster default values, perform the

following for each controlled device (control loop):

1. Verify that controlled devices (cooling coil valve [CCV],

heating coil valve [HCV]) are properly piped and wired.

2. Using the local interface device, force each controlled

device fully open and fully closed. Make sure the ac-

tuators move smoothly. Sticky or sloppy actuators result

in poor control. They must be corrected, otherwise it may

be impossible to obtain stable control.

3. Verify that all appropriate energy sources are available:

hot water, chilled water, steam, etc.

4. Verify that the system is in the Occupied mode and the

supply fan is running.

5. Verify that the supply fan status indicates ON. If the fan

status if OFF, the control algorithms hold the controlled

devices at the failsafe position.

6. Verify that all forces have been removed.

7. Table 24 indicates recommended starting values for SMG,

MPG, and MIG for constant volume and variable air vol-

ume units. Verify that these values have been entered.

8. Verify/adjust the SMG. If the SMG is too large, the loop

tends to oscillate (hunt). If it is too small, the loop reacts

too slowly.

Verify or adjust the SMG as follows:

a. Using the local interface device, force the submaster

reference of the control loop to a value above or be-

low the actual sensor reading. Verify that the actua-

tor responds correctly. If the actuator drives in the

wrong direction, go to the submaster gain (SMG) for

the control loop and reverse the sign of the gain. For

example: If the submaster loop gain is 5.0, change it

to −5.0.

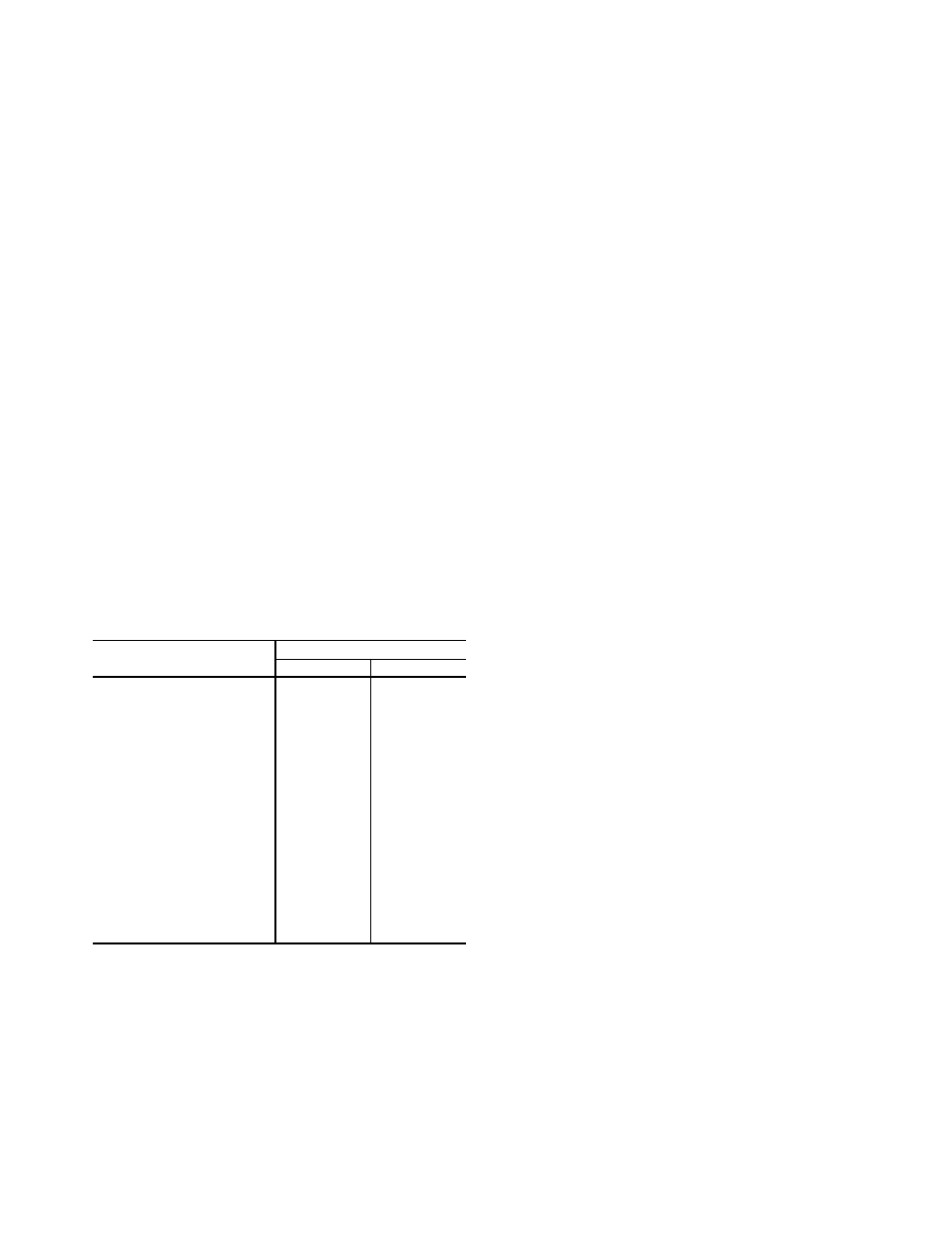

Table 24 — Recommended Gain Starting Valves

GAIN

VALUE

CV

VAV

HCV MPG

8.0

0.3*

HCV MIG

0.3

1.5*

HCV SMG†

−7.5

−7.5

CCV MPG

8.0

0.3*

CCV MIG

0.3

1.0*

CCV SMG**

−7.5

−7.5

MIXD MPG

8.0

0.5*

MIXD MIG

0.3

1.5*

MIXD SMG

−7.5

−7.5

IGV MPG

—

0.5

IGV SMG

—

5.0

EH MPG

8.0

8.0

EH SMG

5.0

5.0

PREHEAT/AO MPG

1.0

0.3

PREHEAT/AO MIG

0.8

0.8

PREHEAT/AO SMG†

−3.0

−3.0

PREHEAT/AO SCV††

100%

100%*

RFVC MPG

—

0.5

RFVC SMG

—

10.0

HUM MPG

2.0

2.0

HUM SMG

7.5

7.5

*Differs from default value; change the default value to obtain the

recommended starting value shown.

†Values shown are for normally-open valves. If normally-closed valves

are used, see Step 8.

**Values shown are for normally-closed valves. If normally-open valves

are used, see Step 8.

††Values shown are for normally-open valves. If normally-closed valves

are used, subtract initial value specified from 100% to obtain the

correct value. Example:

100% − (SCV N.O.) = (SCV N.C.)

100% − 100% = 0%

b. Observe the operation of the controlled device for a

few minutes. If the device oscillates every few sec-

onds around the forced value, then lower the SMG

by small amounts until the output steadies. If the out-

put to the device responds to a change in temperature

in small increments, then increase the SMG in small

amounts until the output steadies.

NOTE: Do not be alarmed if the submaster sensor sta-

bilizes at a value greater than or less than the forced

value. This is termed the submaster droop offset and is

normal.

9. It is not necessary to adjust the submaster loop center

value, as the master loop will adjust the submaster ref-

erence as required to satisfy its set point. However, it

may be desirable to keep the submaster droop to a mini-

mum. This is most often required for heating coil loops,

(especially on steam coils where the control valve has a

tendency to be oversized).

If the submaster droop is too large, adjust the SCV as

follows:

If the submaster droop is positive (actual value greater

than reference value), the SCV should be decreased for

HCV and IGV loops and increased for CCV and MIXD

loops. If the submaster droop is negative (actual value

less than reference value), the SCV should be increased

for HCV and IGV loops and decreased for CCV and

MIXD loops.

10. Once the submaster loop is adjusted, remove all forces

and proceed with verification and adjustment of master

loop.

11. To check the master loop, create an error in the master

loop. For example: Change the actual space temperature

to a value less than the heating set point or greater than

the cooling set point.

Observe system (loop) response for 10 to 20 minutes to

verify stable control. After 10 minutes if the output con-

tinues to swing full open to full closed, lower the MPG

and observe again. Do this until the loop operation is

stable. After 10 minutes, if the loop does not seem to

respond (little change in submaster reference), increase

the MPG and observe again. Do this until stable opera-

tion is achieved.

12. Once you are satisfied with loop operation, remove all

forces which may have been initiated during this

procedure.

13. Repeat steps 1-12 until all loops have been checked.

VALVE TROUBLESHOOTING

General —

To facilitate troubleshooting the valve, it may

be necessary to disassemble the electronic actuator from the

valve body.

All

1

⁄

2

-in. Through 1

1

⁄

4

-in. Electric Hot Water/

Steam Valve Assemblies —

A high-temperature link-

age extension is supplied to help insulate the hydraulic ac-

tuator from heat. See Fig. 80. Mount valves so that valve

stem is at a 35° to 45° angle from vertical. See Fig. 81.

109