Unit troubleshooting (cont) – Carrier 39L User Manual

Page 114

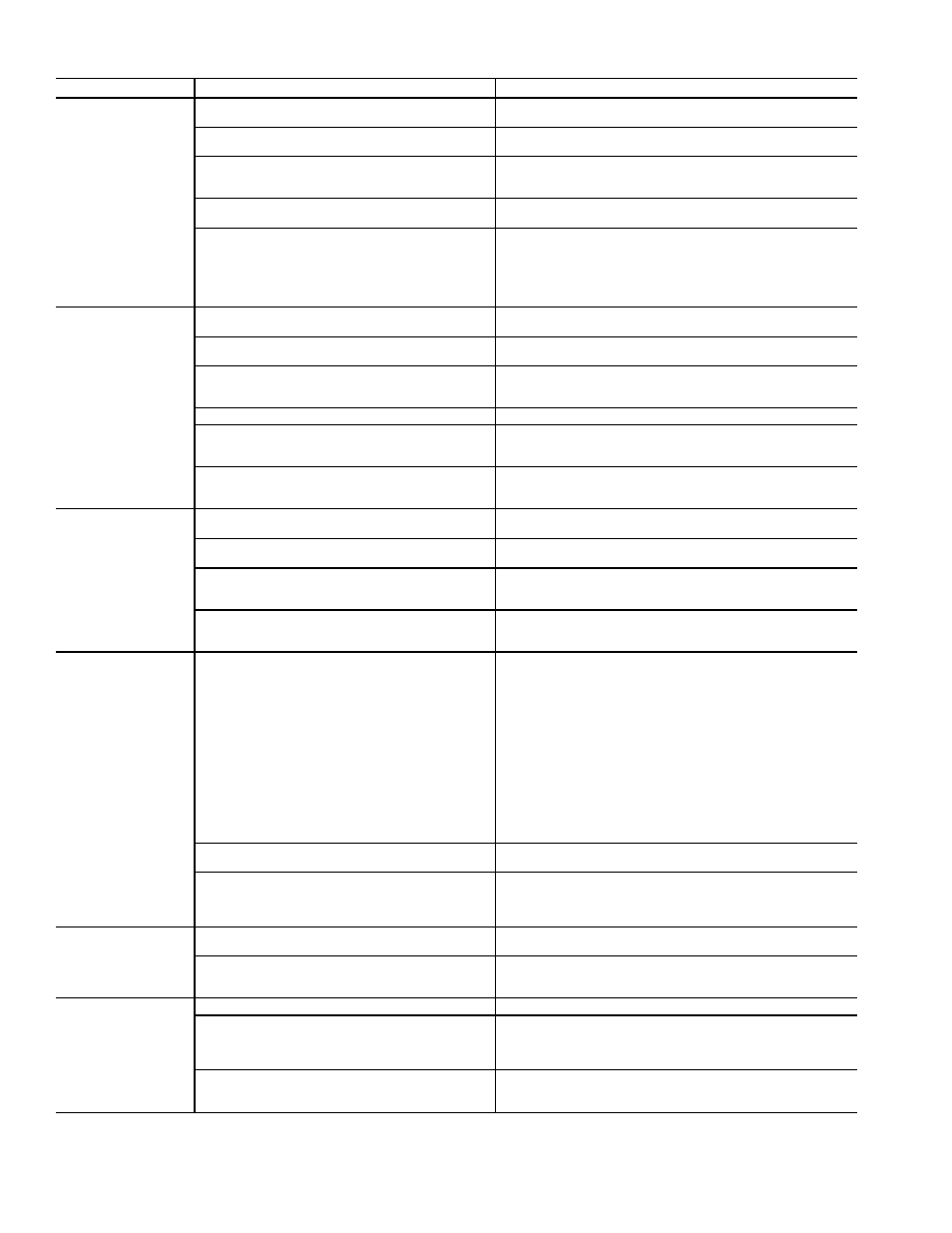

UNIT TROUBLESHOOTING (cont)

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Mixed-air dampers

will not operate

No fan status

Check status of SFS (4 STAT). If supply fan status switch is

OFF, check switch for proper operation.

Mixed-air dampers forced closed to outside air

Check status of MIXD (5 STAT). If MIXD is forced, remove

force and check operation.

No power to damper actuator

Check for blown fuse (F7). Replace if necessary. If fuse is

intact, check for proper connections. Check transformer

output.

Incorrect reading from space temperature sensor

or supply-air temperature sensor

Check status of sensor readings for accuracy. Replace sen-

sors if defective.

Configuration error

Check configuration for proper SMG and MDP (minimum

damper position). If MDP is set to zero, then dampers will

stay closed when enthalpy is unsuitable. An improper SMG

can cause the MIXD to be held to the MDP setting. Check

for proper damper set point. If damper set point is forced to

incorrect value, remove force.

Unit not main-

taining desired

static pressure

(VAV units only)

No fan status

Check status of SFS (4 STAT). If SFS is OFF, check supply

fan status switch for proper operation.

Inlet guide vanes (IGVs) forced closed

Check status of IGV (5 STAT). If IGVs are forced, remove

force and check operation.

No power to IGV actuator(s)

Check for blown fuse (F4). Replace if necessary. If fuse is

intact, check for proper connections. Check transformer for

proper output.

Loose IGV linkage

Check IGV linkage for tightness and proper adjustment.

Incorrect reading from static pressure transducer

Check status of sensor reading for accuracy. If reading is

in error, check for plugged sensing line and check sensor

calibration. Replace sensor if defective.

Configuration error

Check configuration for proper static pressure set point.

Also, check SMG. An improper SMG can cause the IGVs to

be held closed.

High-Pressure

Switch keeps

tripping unit

OFF (VAV only)

IGVs forced open

Check status of IGV (5 STAT). If IGVs are forced, remove

force and check operation.

High-Pressure Switch (HPS) is incorrectly set

or defective

Using squeeze bulb, check trip point of HPS. Adjust as re-

quired. Check for plugged lines. Replace if defective.

Static pressure sensor reads incorrectly

Using local interface device and squeeze bulb with gage,

verify static pressure reading is correct. Adjust or replace

sensor as required.

Configuration error

Check configuration for proper static pressure set point.

Check SMG. An improper SMG can cause the IGVs to be

held open.

Individual

actuators

do not function

No power, blown fuse

Check fuses of specific actuator for function failure.

Fuses are as follows:

F1 — PSIO control module

F2 — Power

F3 — Cooling coil

F4 — IGVs — supply fan

F5 — DSIO or option module

F6 — Heating coil

F7 — Mixed-air dampers

F8 — Smoke control or return-air damper

F9 — Exhaust-air damper

F10 — IGVs — return fan

F11 — 39NX sizes 74, 92; 2nd IGV actuator, supply fan

F12 — 39NX sizes 74, 92; 2nd IGV actuator, return fan

F13 — Preheat coil

Linkage is jammed or binding

Using manufacturer’s instructions, correct and adjust

linkage. Check operation.

No control signal

Using Quick Test and a voltage meter set to measure cur-

rent, verify that the proper control signal (4 to 20 mA) is be-

ing sent to the actuator. Refer to wiring diagram for

appropriate terminals.

Oscillating

output

(HCV, CCV, IGV,

MIXD, etc.)

Incorrect submaster gain

Using Control Loop Checkout procedure, page 108, adjust

the SMG until the output steadies.

Input sensor is fluctuating (supply-air

temperature sensor, static pressure transducer)

Verify sensor reading. If reading is fluctuating, determine

cause (i.e., loose connections, partially plugged static pres-

sure sensing lines). Correct or replace sensor if necessary.

Sensor

not reading

correctly

Loose connections

Verify all connections are secure.

Sensor out of calibration

Voltage type sensors (i.e., static pressure, space tempera-

ture, outdoor-air temperature, return-air temperature, rela-

tive humidity, and velocity pressure) can be calibrated using

manufacturer’s instructions.

Defective sensor

If a sensor cannot be calibrated and its reading is consid-

ered unacceptable, replace sensor. Once sensor is re-

placed, verify new sensor is reading correctly.

114