Carrier 39L User Manual

Page 112

If only the PSIO slave or DSIO module indicate commu-

nication failure, check the affected module for proper seat-

ing. If the condition persists even though connections are

correct, replace the module as described in the following

section.

Module Replacement (PSIO, DSIO) —

The PSIO

master module controls the standard unit functions, the PSIO

slave module controls many optional functions, and the DSIO

module controls electric heat and/or DX cooling. If the mod-

ule LEDs are not blinking and the unit or features associated

with the module do not work, the module may need to be

replaced. Before replacing an inoperative module, check to

ensure that:

• The PIC control box power is on

• Power at the processor module is between 18 and 24 vac

• No fuses are blown

• All connections are firmly in place

If all of the preceding conditions exist, and the module

LEDs are not blinking, the module needs to be replaced.

Before replacing a processor (PSIO) module, store the con-

figuration data from the old module on hard copy. The new

processor module can be preconfigured or configured in the

field.

After obtaining a new module, field-replace the inopera-

tive module as follows:

1. Turn off all power to the fan motor starter and PIC con-

trol box.

To avoid electrical shock and equipment damage,

always disconnect all power to the control box be-

fore replacing PIC modules.

2. Open the control box door.

3. Refer to Fig. 5-7 for control box component arrange-

ments. Disengage all connectors from the module.

4. Use a screwdriver to remove the mounting screw

securing the module to the control box. Remove the

module.

5. Install the replacement module and replace the mount-

ing screw.

6. Reinstall all connectors. Verify that each connector is in

the correct location.

7. Turn on the power to the PIC control box and motor

starter.

8. If you are replacing a PSIO master module that is not

preconfigured, use the local interface device (HSIO) or

Building Supervisor to reset the date and time and change

the module’s default settings. The original PSIO master

module was factory configured to match the unit in which

it was shipped. A replacement PSIO master mod-

ule must have the Factory Configuration (

) de-

faults changed in the field to match the configuration

of the unit in which it is being installed. Other settings

may also need to be reconfigured to match the unit con-

figuration and/or the original module’s settings.

9. Perform the Initial Check, run the Quick Test, and verify

that the unit is operating correctly as described in the

Start-Up section on page 103.

10. Close the PIC control box door.

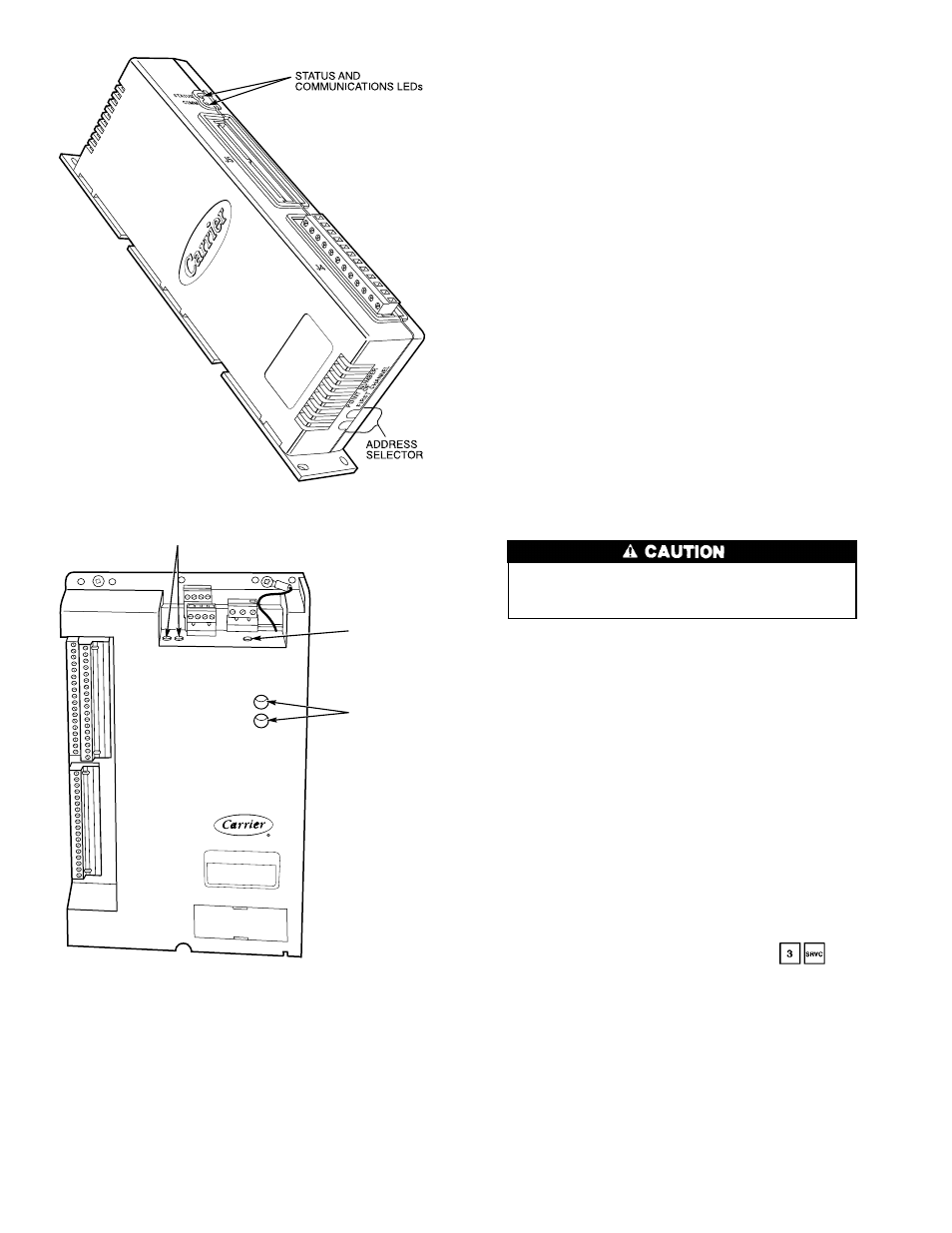

ADDRESS

SELECTOR

STATUS LED

COMMUNICATIONS

LEDs

Fig. 83 — Module Address Selector Switch

and LED Locations

DSIO

PSIO

112