2 physical modbus rs485 wiring, E8 controller and bcm for modulex ext – AERCO Modulex E8 Controller (and BCM) For Modulex EXT Boilers User Manual

Page 83

E8 Controller and BCM for Modulex EXT

Installation, Operation & Maintenance Manual

CHAPTER 8: BOILER COMMUNICATION MODULE (BCM)

OMM-0093_0A

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page

83 of 108

GF-136-C

Ph.: 800-526-0288

PRI: 06/24/2013

and 7 of connector Y2 (see Figure 8-5). In addition, the BCM Fault Relay will be activated and

the red Fault LED (DL2) will light.

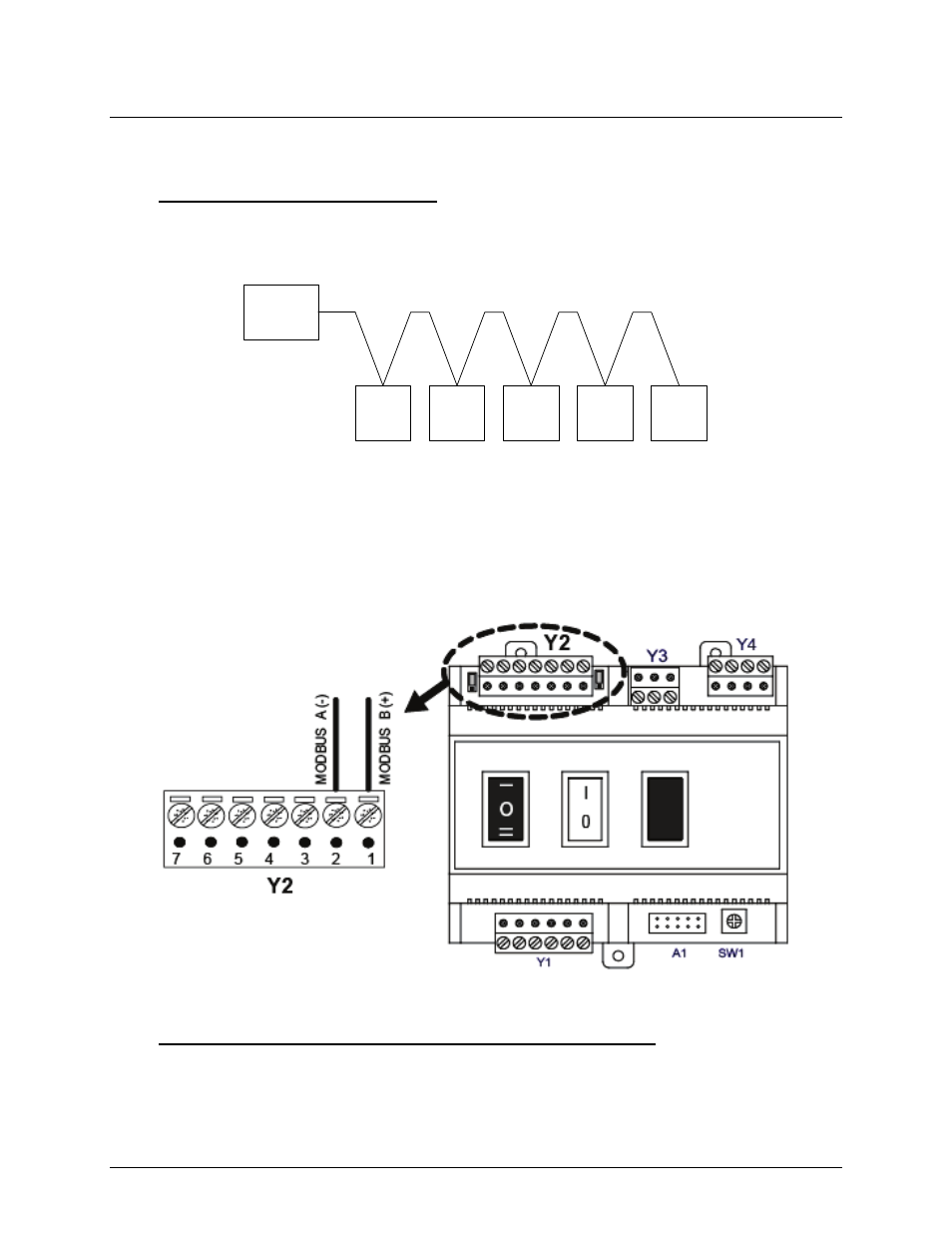

8.4.2 Physical Modbus RS485 Wiring

Modbus RS485 devices should be wired in a “Daisy-Chain” configuration similar to the example

shown Figure 8-6. DO NOT wire the units in a “Star” configuration where all devices are

connected to a central point (node).

Figure 8-6. Typical Daisy-Chain Modbus/RS485 Network

The physical wiring connections for a Modbus Network should be made using shielded twisted-

pair wire, from 18 to 24 AWG. Examples of suitable wire are: Belden # 9841, #8761, #3105A, or

equivalent.

Modbus wiring connections are made at terminals 1 and 2 of BCM connector Y2 as shown in

Figure 8-7.

Figure 8-7: BCM Modbus (RS485) Connections

8.4.3 Disconnecting the E8 from the E-Bus on the BCM Board

See Table 8-1 for how to set the three position switch on the BCM to allow disconnection of the

E8 from the BCM.

NOTE

When the BCM is configured as the primary controller, the E8 will

display the fault code “E200”.

MASTER

SLAVE

#1

SLAVE

#2

SLAVE

#3

SLAVE

#4

SLAVE

#5