General installation – Oldcastle BuildingEnvelope CW-250 User Manual

Page 6

6

February 2012

C W - 2 5 0 C U R T A I N W A L L

I N S T A L L A T I O N M A N U A L

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

Please note that Oldcastle BuildingEnvelope™ does not control the application, nor the selection of its

product configurations, sealant or glazing materials and assumes no responsibility; therfore, it is the

responsibility of the owner, architect and installer to make these selections in strict compliance

with applicable laws and building codes.

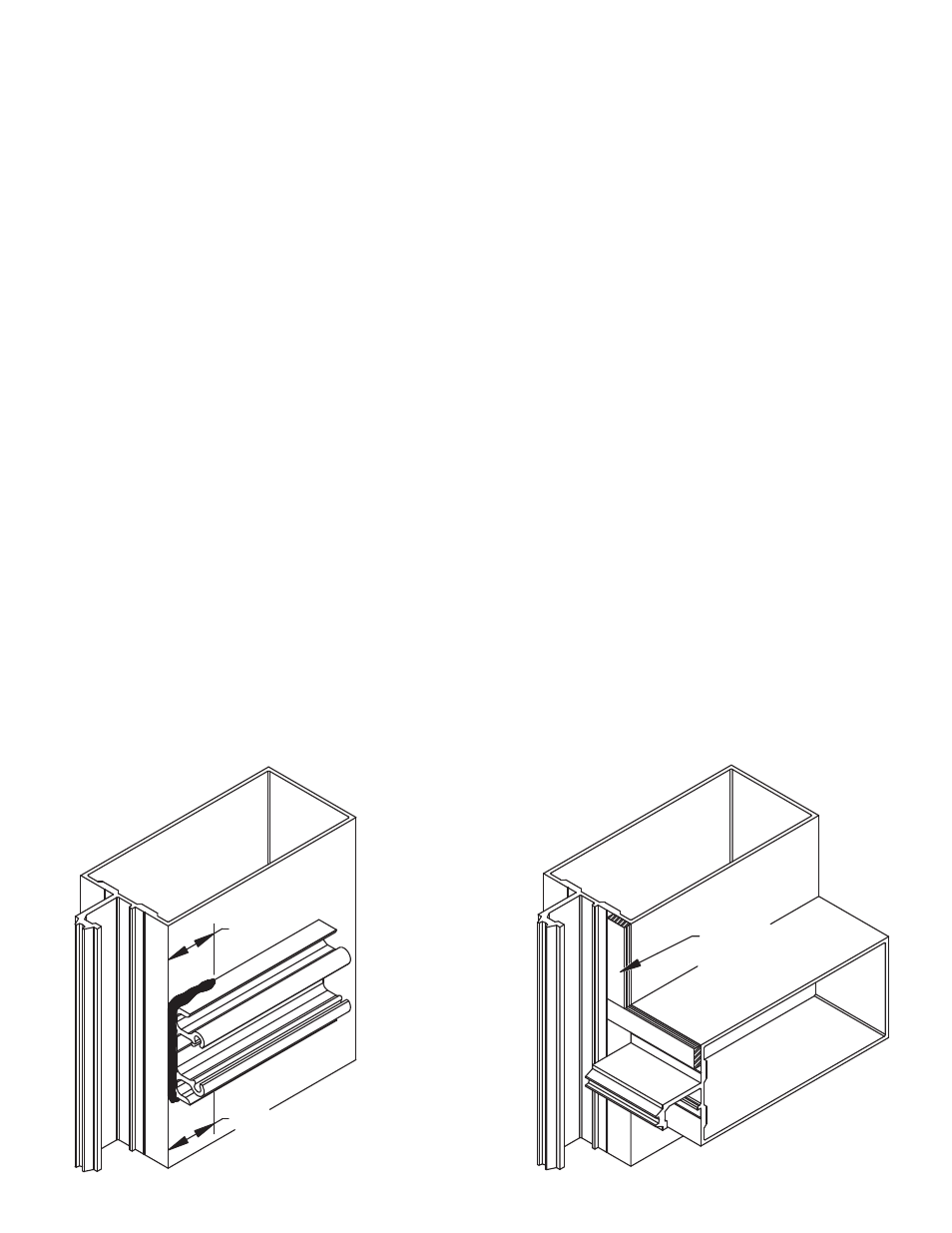

The air and water performance of the outside glazed CW-250 system is directly related to the

completeness and integrity of both the seal installed at the shear blocks, and the glazing gasket

installed at the interior side of the glass, as well as, proper installation of all pressure plates. To

insure top performance for this system, particular note should be made by the following

procedures:

Surfaces to be sealed should be cleaned with isopropyl alcohol or solvent as recomended by

sealant manufacturer to remove all dirt and cutting oils, then dried completely. sealant at shear

blocks should be a minimum nominal 3/16" dia., placed completely around top, face and bottom of the

shear block, without misses or skips. wipe exposed surfaces clean after installing horizontal.

Inspect joint for complete sealant contact, especially where the horizontal intersects the face of

the vertical member and repair as required. consult sealant manufacturer for review and

recommendation of sealant application. follow sealant manufacturers recommendations and

literature for proper installation.

The interior glazing gasket should be installed flat and true to the vertical and horizontal

surfaces without stretching, folds, buckles or tears. corners must be cut square, sealed and

butted. to avoid damage to gasket when glazing; glass should be level and straight when setting

glass against gasket.

Vertical movement of mullions at intermediate floors requires special expansion joints and glazing

materials. See pg. 29 for details which permit ± 1/4" movement.

For designs which may require greater movement or special considerations; please contact

Oldcastle BuildingEnvelope™ engineering.

CW-1636

3/4”

3/4”

FOAM GASKET

GENERAL INSTALLATION