Pressure plate-install, Pressure plate installation – Oldcastle BuildingEnvelope CW-250 User Manual

Page 18

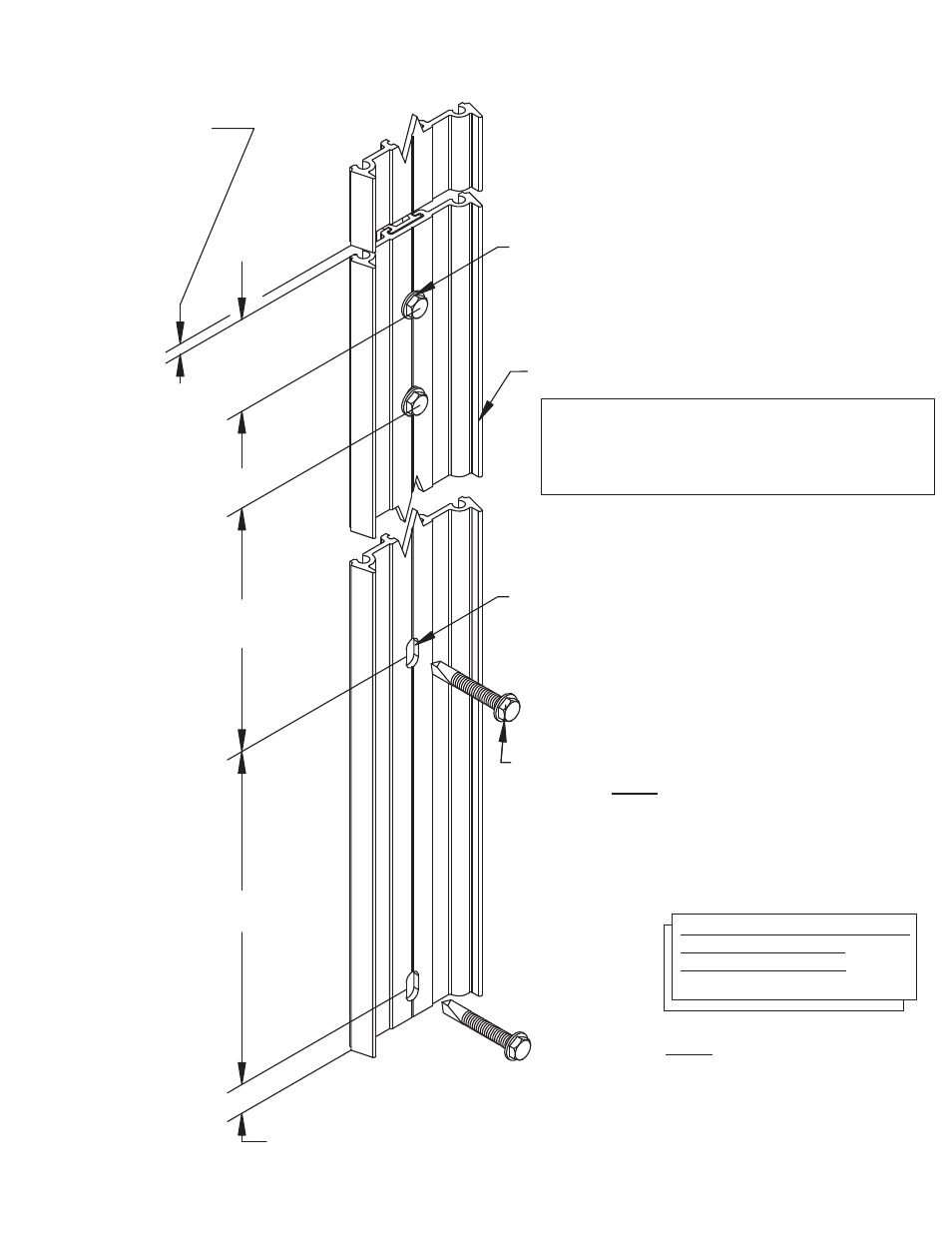

PRESSURE PLATE INSTALLATION

18

February 2012

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

4"

MAX

12"

12"

1/2"

TYP.

1/8" GAP BETWEEN

PRESSURE PLATES-

FILL W/ SEALANT

DRILL 7/32" CLEARANCE

HOLE AT END OF PRESSURE

PLATE FOR FS-322

FACTORY PUNCHED SLOTS

@ 12" O.C.

FS-322 SELF-DRILLING

FASTENER (NOTE: FASTENER

CENTERED IN SLOT TO ALLOW

FOR EXPANSION.)

TORQUE TO MINIMUM 60. IN LBS.

AND MAXIMUM 80 IN LBS

NOTE: VERTICAL APPLICATION

SHOWN: HORIZONTAL

APPLICATION SIMILAR

NOTE: ALL STANDARD PRESSURE

PLATES ARE PRE-PUNCHED WITH

CW-6 ISOLATOR:

STOCK LENGTH=12'-3"

CW-3

NOTE: DO NOT ATTACH PRESSURE

PLATE TO MULLION STEM DIRECTLY W/ FS-322. A

CLEAR HOLE IS REQUIRED IN PRESSURE PLATE.

C W - 2 5 0 C U R T A I N W A L L I N S T A L L A T I O N M A N U A L