Maintenance & storage, General maintenance procedures – Wheatheart Swing Away Flex Auger User Manual

Page 93

W

HEATHEART

- SA F

LEX

A

UGER

6. M

AINTENANCE

& S

TORAGE

71’ - 111’

6.1. G

ENERAL

M

AINTENANCE

P

ROCEDURES

30651 R5

95

6. Maintenance & Storage

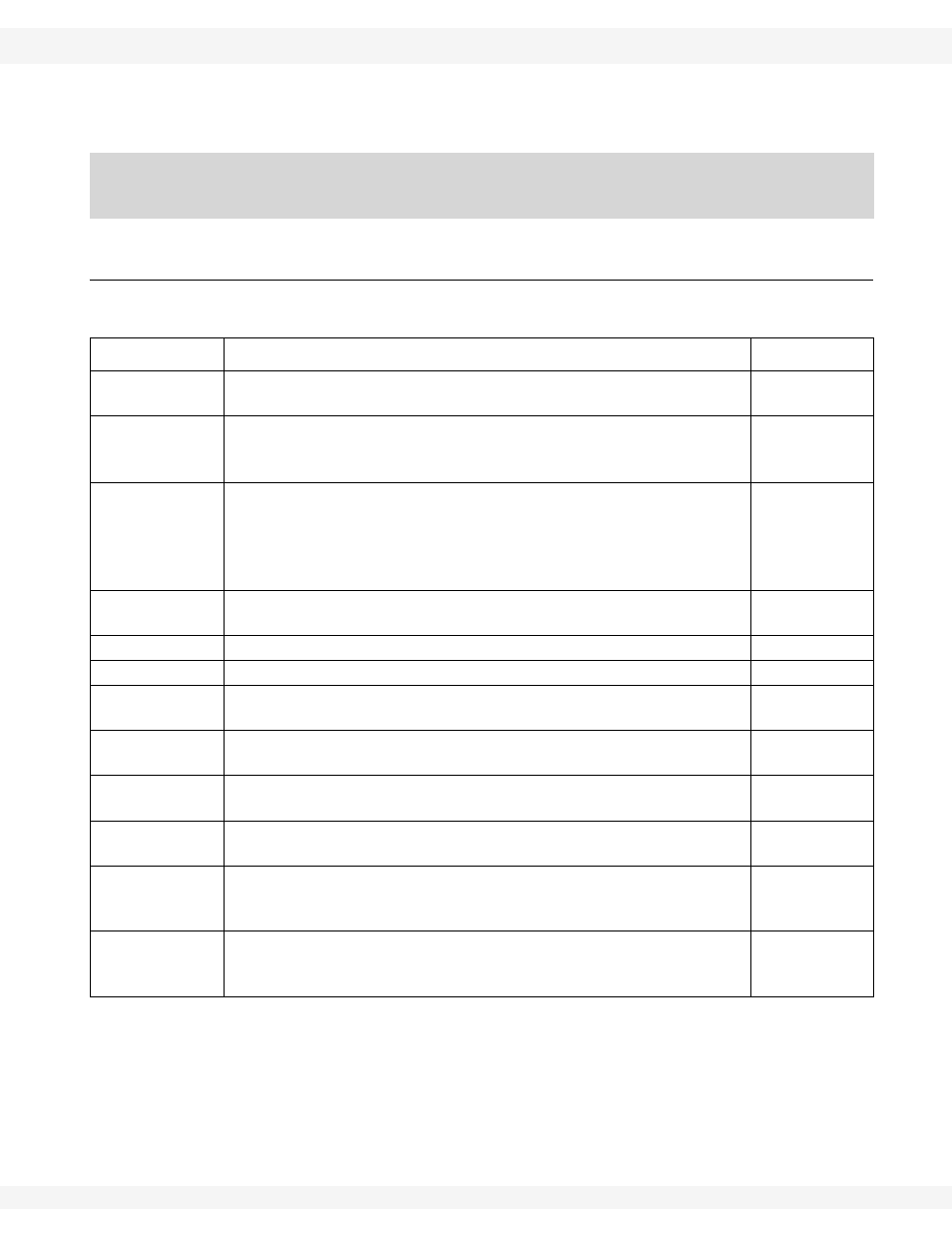

6.1. GENERAL MAINTENANCE PROCEDURES

Please follow the guidelines below.

WARNING Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.

Area

Maintenance Procedures

Frequency

General

While auger is in use, observe the “Pre-Operational Checklist” on

page 87.

Daily

General

Check all operating, lifting, and transport components. Replace

damaged or worn parts before using auger.

• For replacement instructions, see “Assembly” on page 21.

Regularly

Hydraulic Hose

Using cardboard as a backdrop, check hose and hose coupler for

leaks, wear, and damage. Replace if necessary. Refer to the

Hydraulic Safety section.

• Replacement hose and hose ends must have a minimum

strength of 2750 psi (18,961 kPa) working pressure.

Frequently

Lift Cable

Check and replace if frayed or damaged. Make sure cable clamps

are secure.

Periodically

Cable Sheaves

Oil sheave pins on lift cylinder.

Twice/year

Truss Cables

Adjust to keep auger tube reasonably straight.

As necessary

Wheel Hubs

Repack with lithium-based grease.

Every 2–3

years

Tire Pressure

Check with a pressure gauge. Pressure should be maintained

according to sidewall recommendations.

Monthly, or if

it seems low

Hopper Lift

Cable

Check and replace if frayed or damaged.

Periodically

Hopper Lift

Cable Pulleys

Oil lightly for easier raising of hopper.

Several times

a year

Outrigger Leg

Cylinders

Lubricate with good quality Lithium Soap Base E.P. Grease meeting

NLGI #2 specifications and containing no more than 1% molybde-

num disulfide (example: Shell Super Duty).

1-2 pumps

Boot Under

Flex Tube

Lubricate with good quality Lithium Soap Base E.P. Grease meeting

NLGI #2 specifications and containing no more than 1% molybde-

num disulfide (example: Shell Super Duty).

4-8 pumps