Operation, Pre-operational checklist, Auger drive & lockout – Wheatheart Swing Away Flex Auger User Manual

Page 85

W

HEATHEART

- SA F

LEX

A

UGER

5. O

PERATION

71’ - 111’

5.1. P

RE

-O

PERATIONAL

C

HECKLIST

30651 R5

87

5. Operation

5.1. PRE-OPERATIONAL CHECKLIST

Operators must observe safety procedures at all times and follow the pre-opera-

tional checklist before each start-up.

Before operating auger each time, the operator must confirm the following:

• All fasteners are secure as per assembly instructions.

• Cable clamps are secure.

• Lift cable is not frayed or damaged.

• Lift cable is properly seated in cable sheaves.

• Hydraulic hoses are in good condition.

• Hydraulic connections are in place and secure.

• PTO driveline is connected and secure.

• PTO driveline shield rotates freely.

• Clean-out door, service door and access covers are in place and secure

and safety discharge door is closed.

• All safety guards are in place and secure.

• Tube alignment is reasonably straight.

• Intake area and discharge spout are free of obstructions.

• Auger wheels are chocked, and if necessary, tractor wheels are chocked

or the parking brake has been engaged.

• Proper maintenance has been performed.

• Tractor and auger are in line or as close to being in line as possible.

• Over center lock under main boot is released to allow it to move during

operation.

• Know how to safely shut down the auger in an emergency.

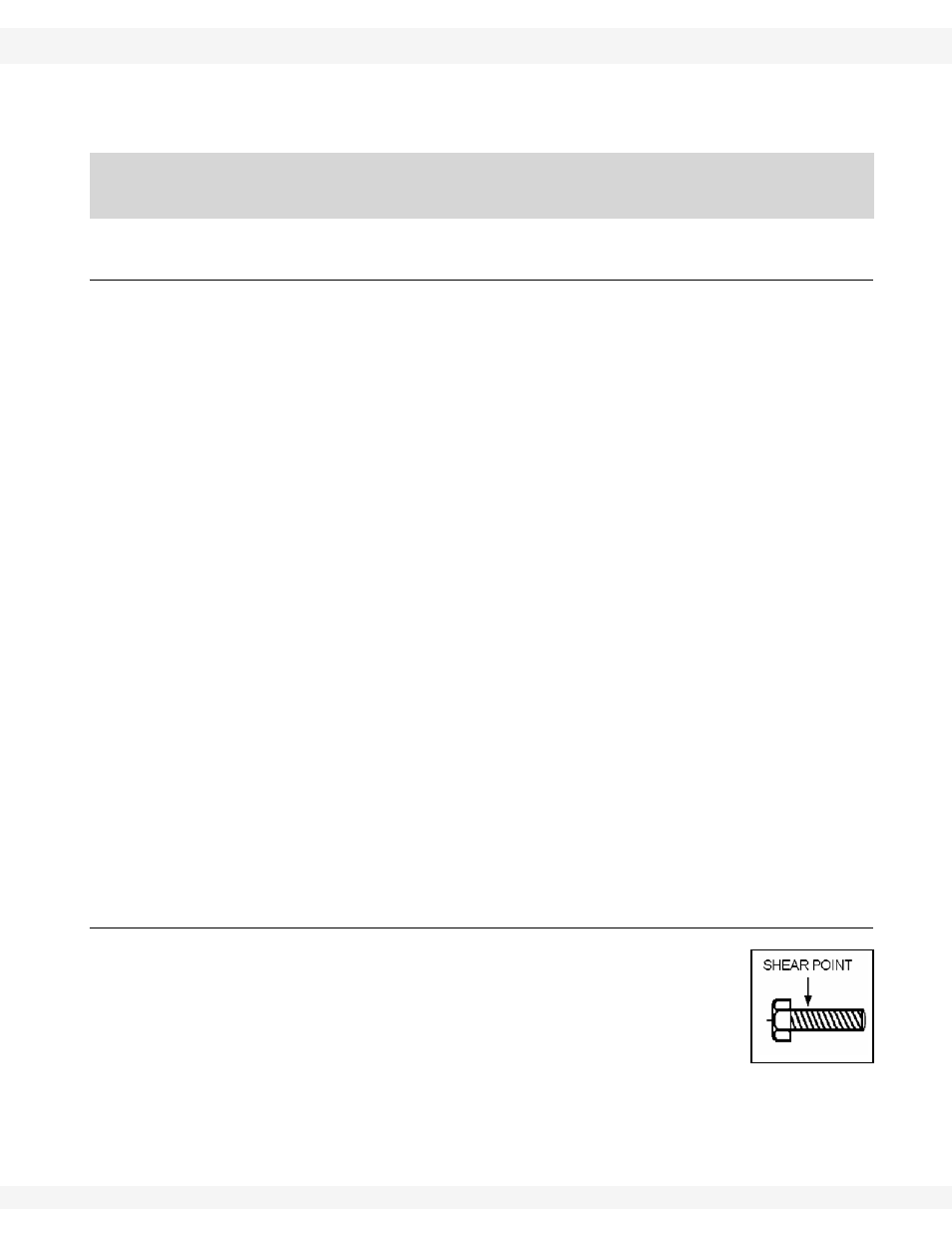

5.2. AUGER DRIVE & LOCKOUT

Note:

If shearbolt in PTO driveline fails, shut down and lock out tractor

to replace bolt.

The Flex uses two 3/8” x 1” grade 5 bolts through the thread

shear.

3/8” x 1” GR5 Bolt part number is 18955.

3/8” Nylon Locknut part number is 17402.

WARNING Before continuing, ensure you have read and understand the relevant information

in the safety section. Safety information is provided to help prevent serious injury, death, or

property damage.