System installation, 5 ssi supplemental safety system hookup, Mmd-ta-11b / mmd-ta-12b muting module – Banner MMD-TA-11B Muting Modules User Manual

Page 31: Instruction manual, Banner engineering corp, Minneapolis, u.s.a

P/N 116390 rev. C

29

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

MMD-TA-11B / MMD-TA-12B Muting Module

Instruction Manual

System Installation

+

A1

Z21

M1

M1

PNP

-

+

PNP

-

+

NPN

-

+

NPN

-

+

+24V dc

EDM1

Safety Mat

Monitor Module

(or Light Screen

Controller)

4-wire Safety Mat

(or horizontally-mounted

Safety Light Screen)

Machine Interface

(see Figures 3-20

through 3-24)

a

b

c

d

EDM2

L2

L1

K1A

K2A

K1B

K1C

K2B

K2C

Override A

Mute

Lamp

(indicator)

Override B

X9

X10

X11

X12

A2

X6

X5

X8

X7

Y1

Y2

Y3

Y4

X1

X2

X3

X4

32

23

24

31

14

MPCE1

Reset

13

Machine

Control

Circuits*

SSI

MPCE2

0V dc

Z23

M3

M3

Z13

Z22

M2

Z24

M4

M4

a

MSSI

OSSD1

OSSD2

b

0V dc

Ground

+24V dc

0V dc

Ground

+24V dc

3-Beam

EZ-SCREEN Grid

(see note above)

c

d

Mute

Enable

(optional)

MMD-TA-11B

Z14

X13

X14

S12

S11

S22

S21

+

-

+

-

+

-

+

-

Z11

M2

Z12

Carrier

Basket

Safe Area

(free movement of personnel)

Hazardous Area

(protected from personnel entry)

Hard Guarding

Safety Mat (or

Horizontal-Mounted

Safety Light Screen)

M1

M2

EZ-SCREEN Grid

Receiver

EZ-SCREEN Grid

Emitter

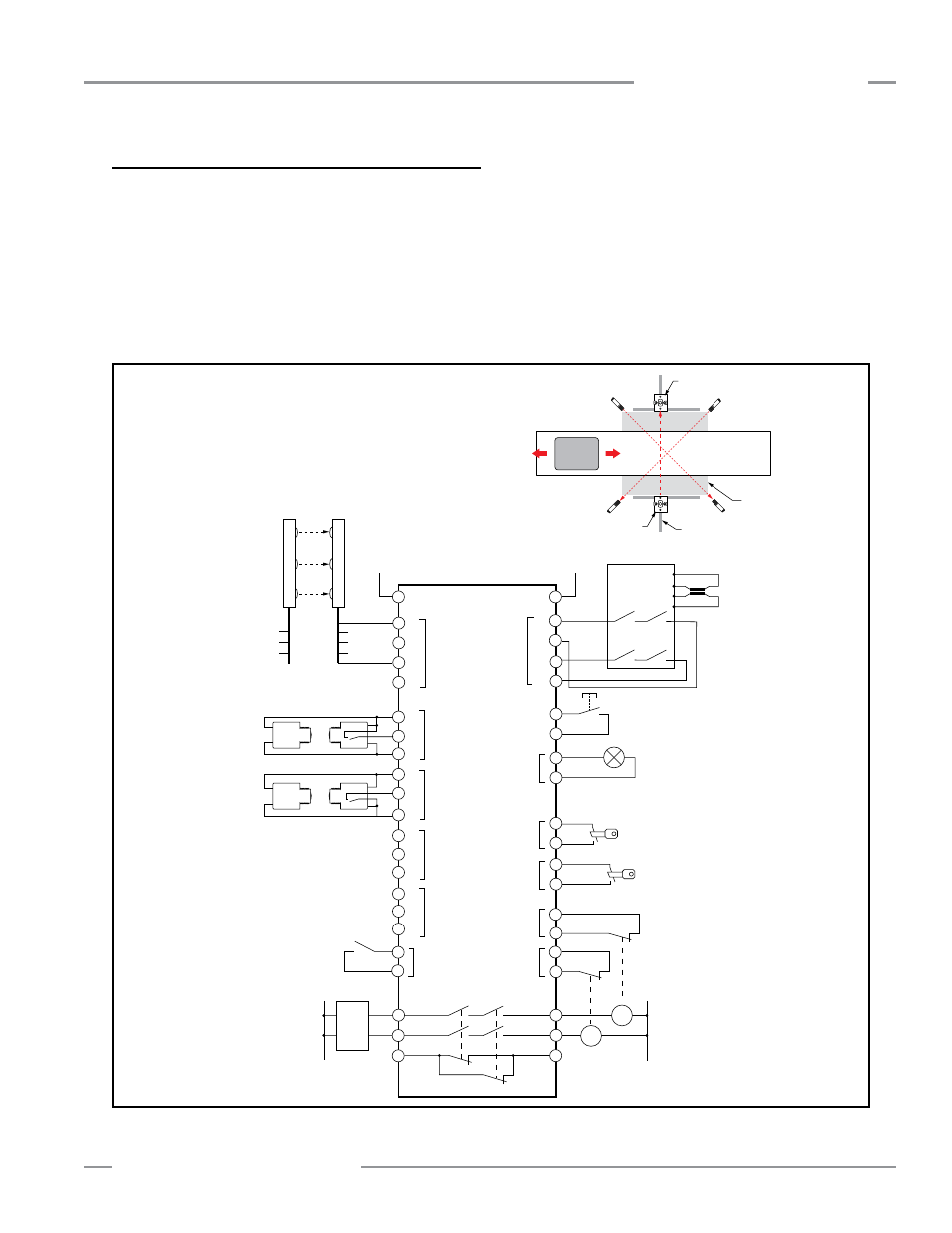

Figure 3-22. Interfacing supplemental safeguarding to prevent personnel from entering the hazardous area during the mute

NOTE: Depending on the application, the 3-beam EZ-SCREEN Grid

system shown typically would be configured for Trip Output

(Automatic Reset). The Muting Module’s manual reset would be

used to reset the system in the event of a stop command being

sent to the machine interface. This allows the EZ-SCREEN to be

interrupted as materials pass through during a muted condition,

without requiring a reset each time a blocked condition occurs.

3.5.6.5 SSI Supplemental Safety System Hookup

A variety of safety systems can be interfaced with the MSSI

and the SSI. Each safety application has a unique set of

application requirements. The user is responsible to ensure

proper installation and use, and that all relevant standards and

regulations are complied with. Figure 3-22 shows a generic

example of the flexibility of the SSI.

Entry/Exit Application with a Multiple-Beam Safety System

(Muted) and a Safety Mat System: see Appendix B for more

information. This application is widely used in a variety of

situations, including manufacturing cells, robotic cells, palletizers,

and de-stackers. One of the many requirements of this muting

application is that it must not be possible for personnel to walk

in front of, behind, or next to the muted object (e.g., the carrier

basket) without being detected and stopping the hazardous

motion.

Figure 3-22 shows how supplemental safeguarding (such as

a safety mat system or horizontal safety light screen) can be

interfaced to prevent personnel from entering the hazardous

area during a mute condition.