System installation, 3 ssi emergency stop switch device hookup, Warning – Banner MMD-TA-11B Muting Modules User Manual

Page 26

24

P/N 116390 rev. C

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

MMD-TA-11B / MMD-TA-12B Muting Module

Instruction Manual

System Installation

Category 2

A single-channel emergency stop application typically provides

a category 2 level of circuit performance, because a short circuit

could cause the loss of the safety function. The principle of fault

exclusion must be incorporated into the design and installation

to either eliminate, or reduce to an acceptable (minimal) level of

risk, the possibility of undetected faults or failures that can result

in the loss of the safety function.

3.5.6.3 SSI Emergency Stop Switch Device Hookup

Emergency Stop Push Button Switches

As shown in Figures 3-16, 3-17 and 3-18, the E-stop switch must

provide one or two contacts for safety which are closed when

the switch is armed. Once activated, the E-stop switch must

open all its safety-rated contacts, and must require a deliberate

action (such as twisting, pulling, or unlocking) to return to the

closed-contact, armed position. The switch should be a “positive-

opening” (or direct-opening) type, as described by IEC 60947-5-1.

A mechanical force applied to such a button (or switch) is

transmitted directly to the contacts, forcing them open. This

ensures that the switch contacts will open whenever the switch

is activated.

Standards ANSI NFPA 79, IEC/EN 60204-1, and ISO 13850

specify additional emergency stop switch device requirements,

including the following:

• Emergency Stop push buttons shall be located at each operator

control station and at other operating stations where emergency

shutdown is required.

• Stop and Emergency Stop push buttons shall be continuously

operable and readily accessible from all control and operating

stations where located. Do not connect E-stop buttons to the

MSSI.

• Actuators of Emergency Stop devices shall be colored Red.

The background immediately around the device actuator shall

be colored Yellow. The actuator of a push-button-operated

device shall be of the palm or mushroom-head type.

• The Emergency Stop actuator shall be a self-latching type.

NOTE: Some applications may have additional requirements.

The user must comply with all relevant regulations.

Safety Circuit Integrity Levels and Emergency Stop functions

As part of the required risk assessment for the machine, ANSI

NFPA 79 and IEC/EN 60204-1 state that the safety performance

(integrity) must reduce the risk from identified hazards as

determined by the risk assessment. See Sections 3.5.6.1 and

3.5.6.2 for guidance if the requirements as described by ISO

13849-1 (EN954-1) are to be implemented.

In addition to the requirements stated above, the design and

the installation of the emergency stop device (e.g., switch,

button, or rope-pull) must be such that the possibility of a

catastrophic failure of the device resulting in the loss of

the safety function must be excluded (designed out). Per ISO

13849-2, electromechanical devices that have contacts designed

in accordance to IEC 60947-5-1 Annex K and that are installed

per manufacturer’s instructions are expected to open when the

emergency stop device is actuated.

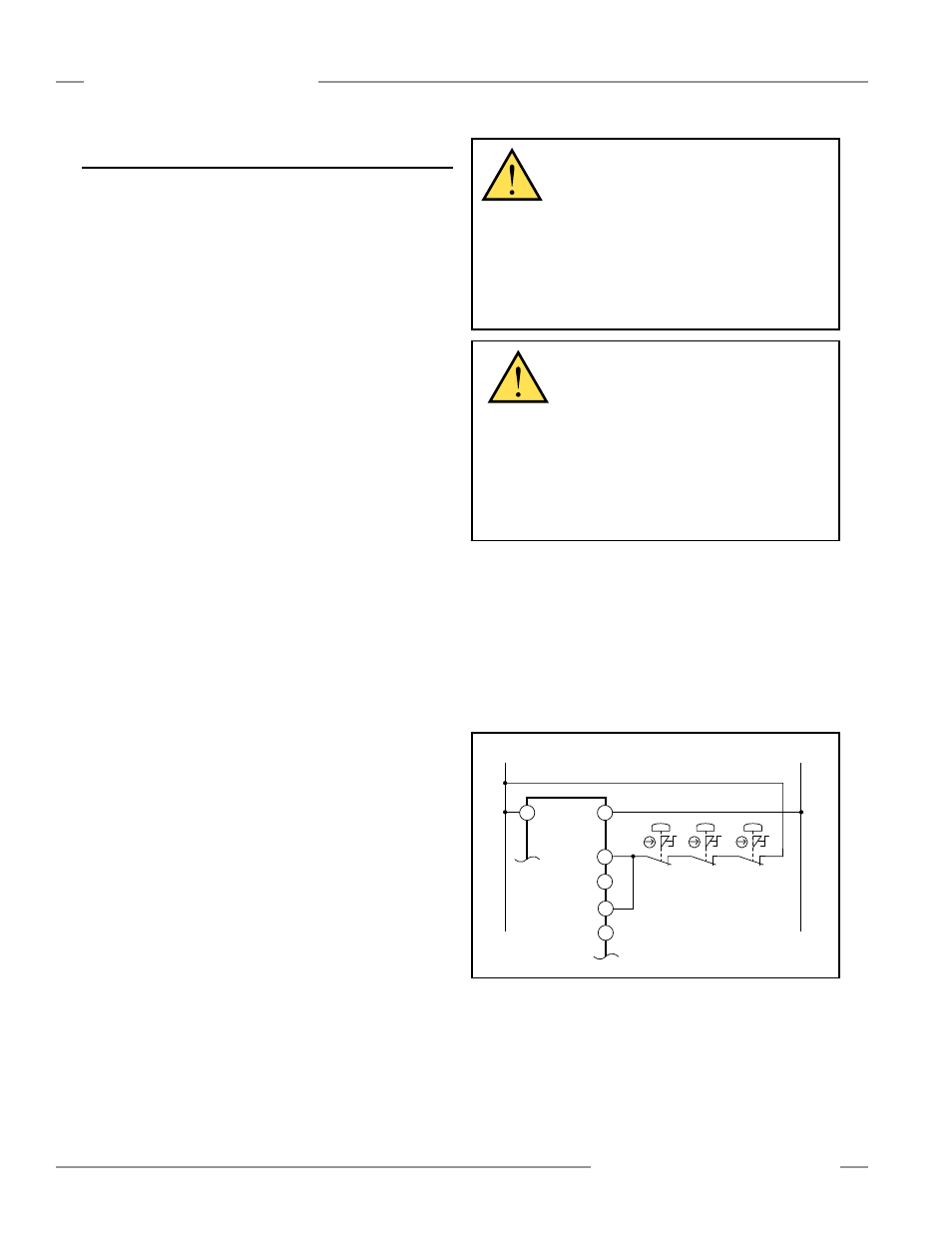

Figure 3-16. SSI Category 2 interfacing: positive-opening

E-stop switch(es)

0V dc

+24V dc

X6 (a)

X5 (b)

X8 (c)

X7 (d)

A2

A1

SSI

MMD-TA-..B

WARNING . . .

Emergency Stop

Functions

Do not connect any device to the MSSI Input

that is used for an emergency stop function. Never mute

or bypass any emergency stop device (e.g., a button or

rope pull). ANSI NFPA 79 and IEC/EN 60204-1 require that

the emergency stop function remain active at all times.

Muting or bypassing the safety outputs will render the

Emergency Stop function ineffective.

WARNING . . .

Reset Routine

Required

U.S. and international standards require that a

reset routine be performed after returning the E-stop switch to

its closed-contact position (when arming the E-stop switch).

When automatic reset is used, an alternate means must be

established to require a reset routine, after the E-stop switch

is armed. Allowing the machine to restart as soon as the

E-stop switch is armed creates an unsafe condition which

could result in serious injury or death.