3 selection of the sample loop, 4 general information on suppressor module, Selection of the sample loop – Metrohm 820 IC Separation Center User Manual

Page 45: General information on suppressor module

2.9 Separating columns and suppressor module

819 IC Detector / 820 IC Separation Center

37

2.9.3

Selection of the sample loop

Selection of the sample loop depends on the separating column used.

Normally, the following sample loops are used:

Anion columns

100

µ

L

Cation columns

10

µ

L

Columns for suppressor technique 20

µ

L

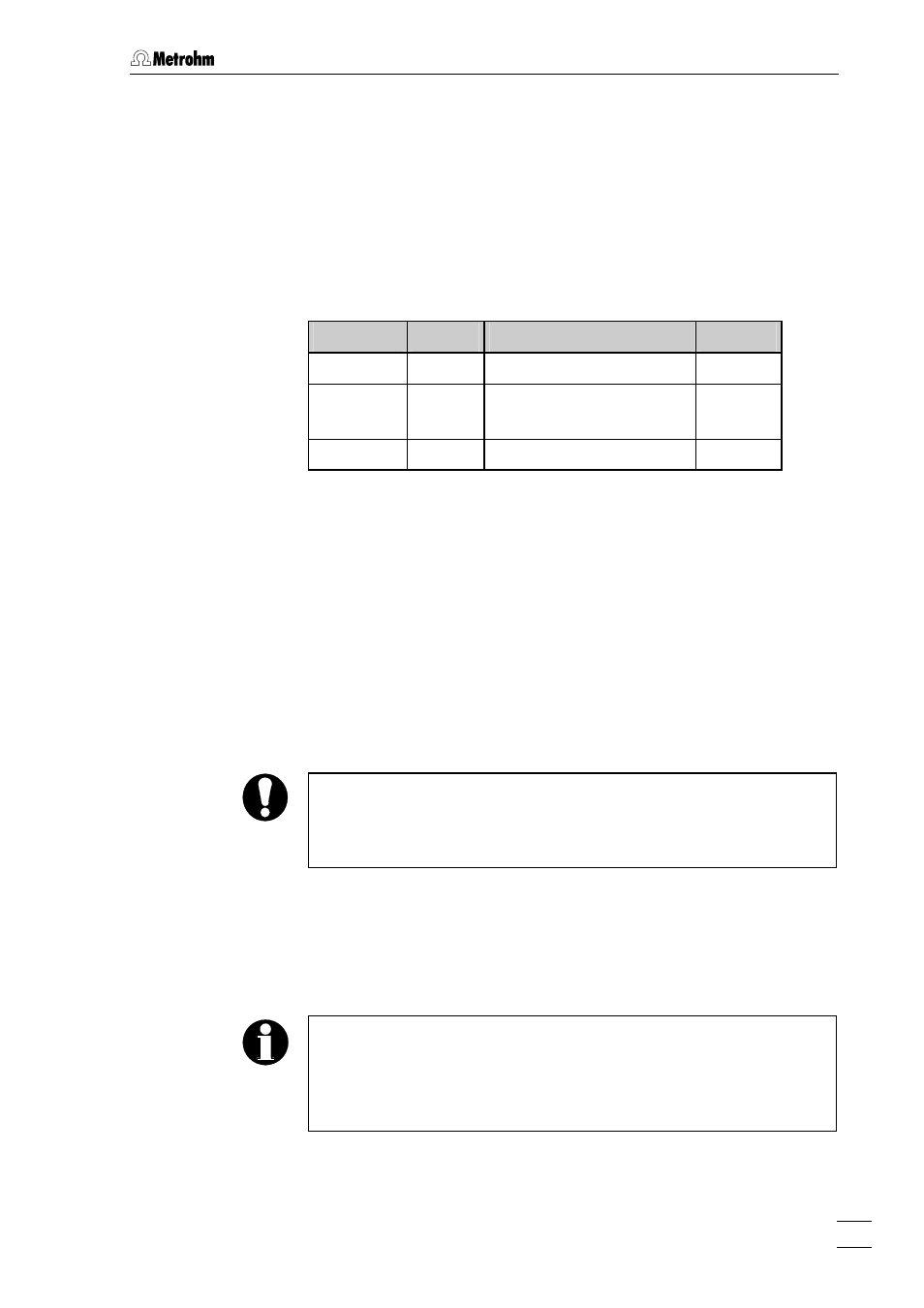

Depending on the instrument version, the following sample loops are

installed in the 820 IC Separation Center:

Version

Valve

Sample loop

Volume

2.820.0X10

A 6.1825.210

(PEEK)

20

µ

L

2.820.0X20

A 6.1825.220

(PEEK)

100

µ

L

B

6.1825.210

(PEEK)

20

µ

L

2.820.0X30

A 6.1825.210

(PEEK)

20

µ

L

If desired, the built-in sample loop can be replaced by one of the sam-

ple loops available as an option (see Section 6.3.1).

2.9.4

General information on suppressor module

The Metrohm Suppressor Module MSM for chemical suppression

installed in the 2.820.0X30 IC Separation Center comprises a total of 3

suppressor units which are in turn used for suppression, regenerated

with sulfuric acid and rinsed with water. To record every new chroma-

togram under comparable conditions, work is normally carried out with

freshly regenerated suppressor. Switching is either automatic together

with the valve switching or manual.

The suppressor units must never be regenerated with H

2

SO

4

in the

same flow direction used for the eluent. You should thus always install

the inlet and outlet capillaries as described in Section 2.9.7 according

to the scheme shown in Fig. 23.

For operation of the suppressor module, a two-channel peristaltic

pump is needed which conveys the regeneration solution (normally

50 mmol/L H

2

SO

4

) and the rinsing solution (normally dist. H

2

O) to the

suppressor units. We advise working with a flow rate of 0.5 mL/min.

The

2.833.0010 IC Liquid Handling Pump Unit is available from

Metrohm as an option. Two lengths of pump tubing (6.1826.050) are

enclosed with this pump (flow rate 0.5 mL/min). Startup and operation

of the 833 Pump Unit is described in the Instructions for Use enclosed

with the pump.

The three inlets and outlets numbered 1...3 on the suppressor module

each have 2 permanently mounted PTFE capillaries, which must be

connected as described in Section 2.9.7 (see Fig. 23 und Fig. 24).