Clicktight, Connectors – Diode LED Solid Color Tape Light User Manual

Page 3

1.877.817.6028

www.DiodeLED.com

www.DiodeLED.com

INSTALLATION GUIDE

3 OF 6

SOLID COLOR LED TAPE LIGHT

®

IG082514-2.4

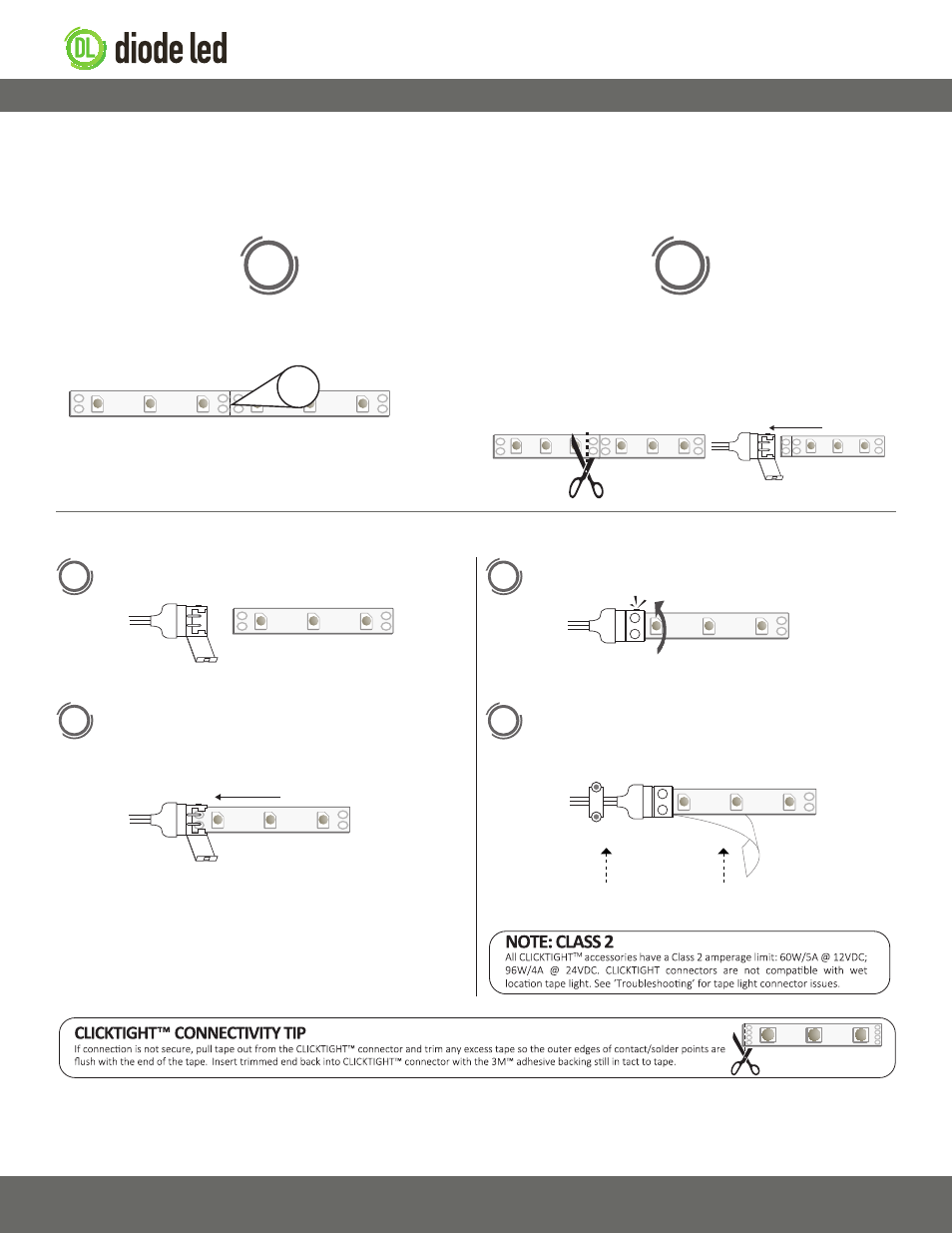

Cut points not drawn to scale

CLICKTIGHT

™

Connectors

1

2

Close the CLICKTIGHT™ latch to ensure connection.

When ready for mounting, peel off the 3M™ adhesive backing

of the tape and tear off along the connector tray edge. Mount

tape light and utilize a wiring harness to secure lead wires.

Open the CLICKTIGHT™ latch and note the +/- polarity markings.

Firmly insert the tape light into the connector tray with the

3M™ adhesive backing still intact to the tape. Ensure the

contact/solder points of the tape are directly underneath the

metal placement tabs of the connector.

3

4

Wiring Harness

3M™ Adhesive

Attaching CLICKTIGHT™ Connectors

–

+

–

+

–

+

–

+

Cutting Tape Light

Cutting tape light densities lower than 2.88W/ft.:

Cut the tape at the cut line indicated with the scissors icon.

Utilizing CLICKTIGHT™ connectors requires specific cutting instructions for high density solid color tape light to achieve a proper connection. See

options A or B (does not apply to RGB tape light). Never cut tape attached to a live circuit. DO NOT solder CLICKTIGHT™ connectors to tape light.

Cutting tape light densities higher than 2.88W/ft.:

DO NOT cut at the scissors icon. Instead, cut the tape along the outside

edge of the LED chip closest to the scissors icon so four contact/solder

points remain intact to the tape. This will ensure the latch of the

CLICKTIGHT™ connector closes properly.

–

+

–

+

–

+

–

+

–

+

–

+

–

+

Tape less than 2.88W/ft.

Tape 2.88W/ft. and higher

–

+

–

+

–

+

–

+

–

+

OR

a

b

–

+

–

+

–

–

+

+