Rockwell Automation SA3100 Power Module Interface (PMI) Regulator User Manual

Page 38

3-4

PMI Regulator

The Resolver & Drive I/O board supports two methods of sampling the digital position

of the resolver. In the first method, the position is sampled once per UDC task scan at

the rate defined in the SCAN_LOOP control block in the UDC task. This block tells

the UDC task how often to run based on the CCLK signal on the AutoMax rack

backplane. The PMI processor sends the position data to the UDC module

immediately before it is needed by the UDC module for the next UDC task scan.

Position data measured using this method is stored in the UDC module’s dual port

register 215/1215 in the format shown in figure 3.3 or 3.4.

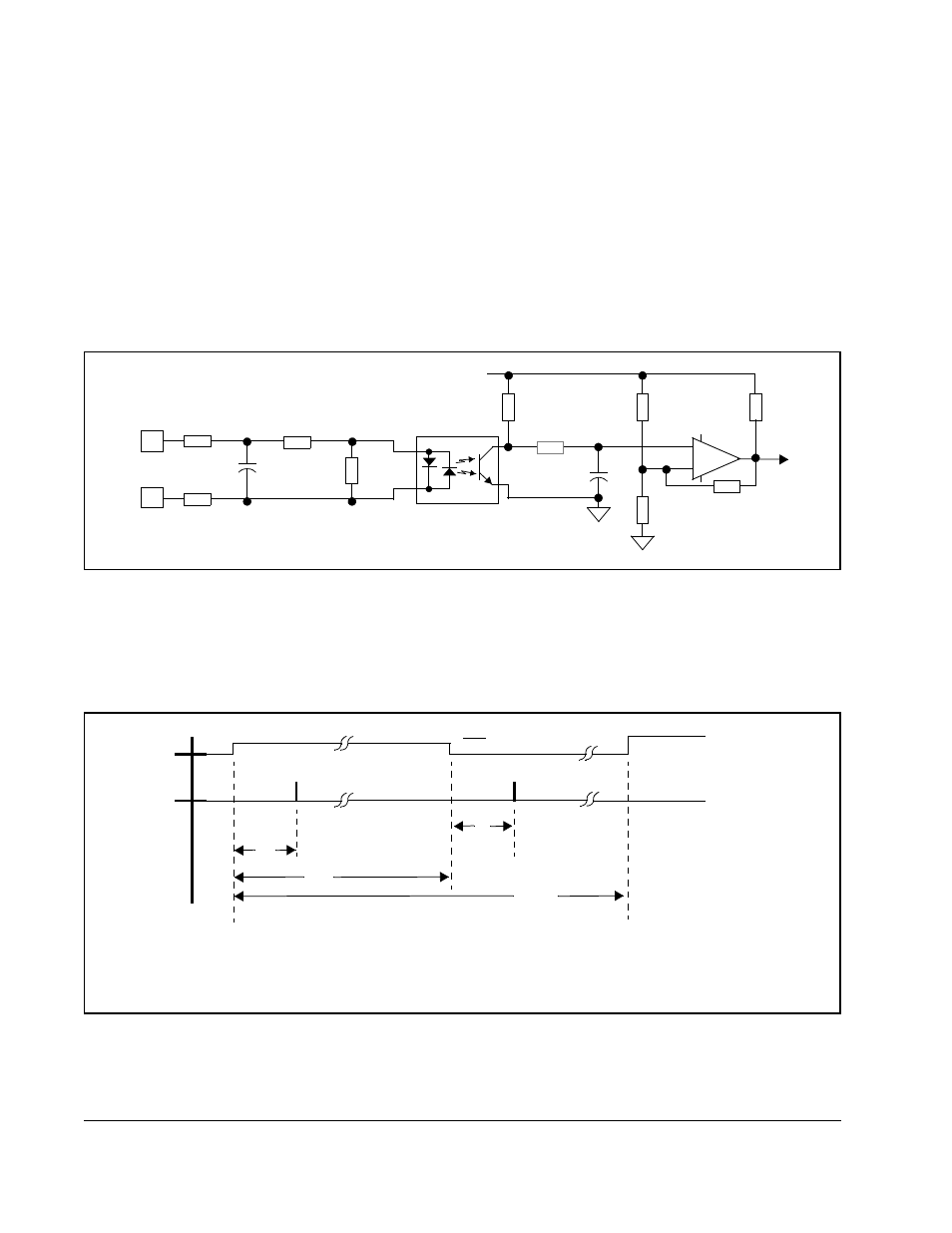

The second method allows position sampling between scans or when an external

event occurs by using an external strobe. The Resolver & Drive I/O board provides an

isolated 24 volt DC input with a relatively high degree of filtering (approximately 800

Hz). The external strobe input circuit is shown in figure 3.5.

Figure 3.6 shows the relationship between the time the external strobe is detected

and the point at which the resolver position is sampled. Response time is subject to

temperature, component tolerance, and input voltage level. Note that the input signal

pulse width should be greater than 300 µsec and the frequency should be less than

1000 pulses per second.

Figure 3.5 – External Strobe Input Circuit

+

-

EXTERNAL

STROBE

INPUT

300

300

.33uF

2.55K

1.24K

5K

Vcc

681K

10K

TO

MICRO-

PROCESSOR

14K

.01uF

681K

475K

Figure 3.6 – External Strobe Input Circuit Timing Diagram

EXT. STROBE

INPUT

RESOLVER

POSITION

LATCH

COMMAND

24 V NOM

T

pw

T

d

T

d

T

per

T

d

- 250

m

SEC TYP.

T

pw

- 300

m

SEC MIN.

T

per

- 1000

m

SEC MIN.