Write ladder logic – Rockwell Automation 1771-QDC, D17716.5.85(Passport) MNL. PLASTIC MOLDING MODULE User Manual

Page 59

Jog Your Machine

Chapter 5

5-5

Take time now to develop ladder logic (independent of Pro-Set 600

software) to jog the ram (screw) with the QDC module. You need to

monitor switches on your operator control panel, and set corresponding

command bits.

Use word 1 in the dynamic command block (DYC01) to enable and disable

individual jogs. Use word 1 in the system status block (SYS01) to monitor

the QDC module’s reaction to jog commands. Tables 5.A and 5.B identify

command and status bits for jogging the ram (screw).

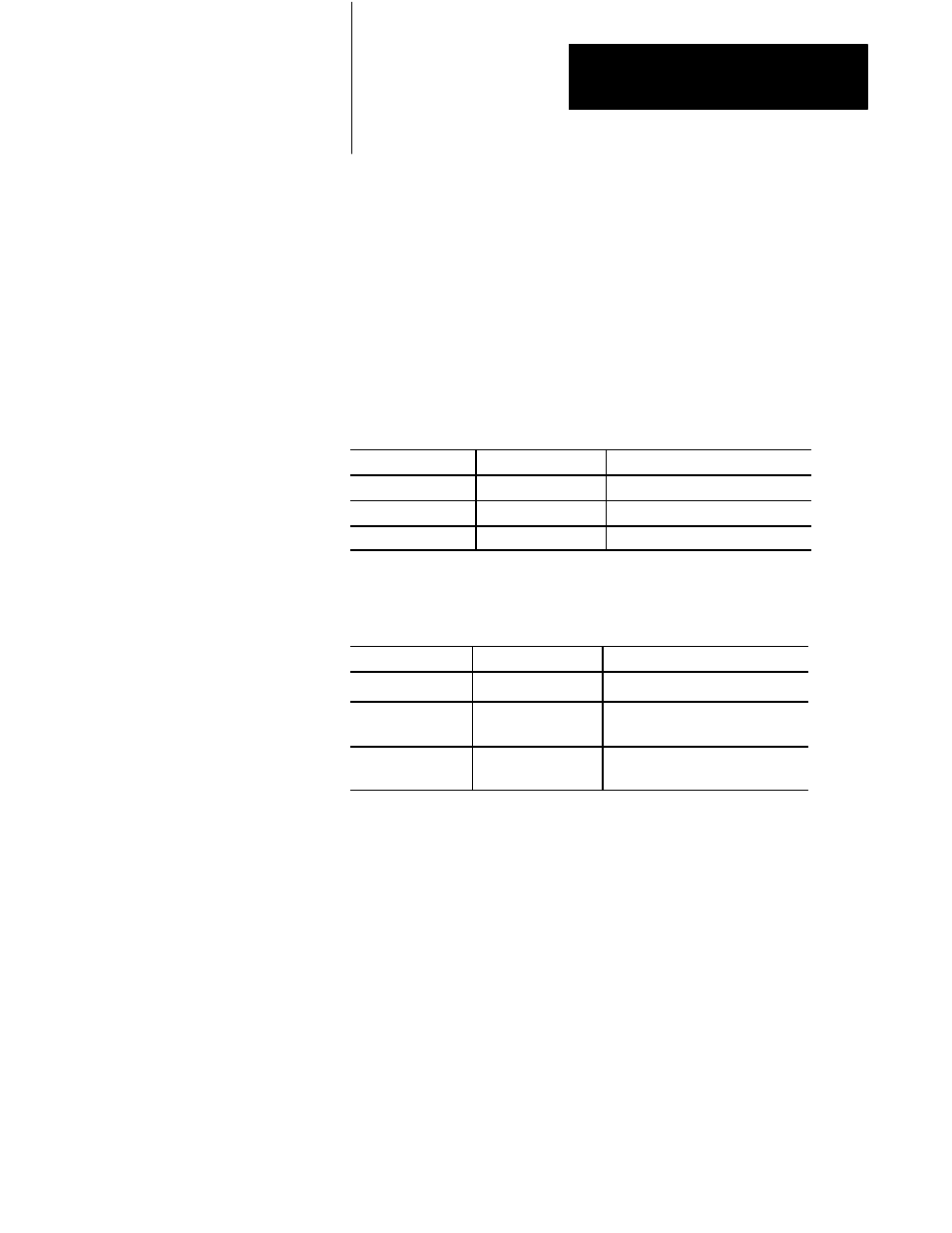

Table 5.A

Ram (Screw) Jog Enable Bits

Control Block Word: ProĆSet 600 Address: Description:

DYC01ĆB09

B34/393

Execute Screw Rotate Jog

DYC01ĆB10

B34/394

Execute Inject Cylinder Jog Forward

DYC01ĆB11

B34/395

Execute Inject Cylinder Jog Reverse

Table 5.B

Ram (Screw) Jog Status Bits

Status Block Word: ProĆSet 600 Address: Description:

SYS01ĆB09

B34/9

Screw Rotate Jog in Progress

SYS01ĆB10

B34/10

Inject Cylinder Jog Forward in

Progress

SYS01ĆB11

B34/11

Inject Cylinder Jog Reverse in

Progress

We provide a programming example (Figure 5.1) of jog control for

instructional purposes only. Your application-specific programming may

vary significantly from this example.

Important: You may also need to develop ladder logic that changes the

direction of ram (screw) travel hydraulically when you command the QDC

module to jog the ram (screw) in reverse.

Write Ladder Logic