Rockwell Automation 1771-QDC, D17716.5.85(Passport) MNL. PLASTIC MOLDING MODULE User Manual

Page 125

Span Your Valves

Chapter 9

9-8

Set New Values for the Velocity vs. Position Profile

If necessary, refer to chapter 8 for when you determine the following:

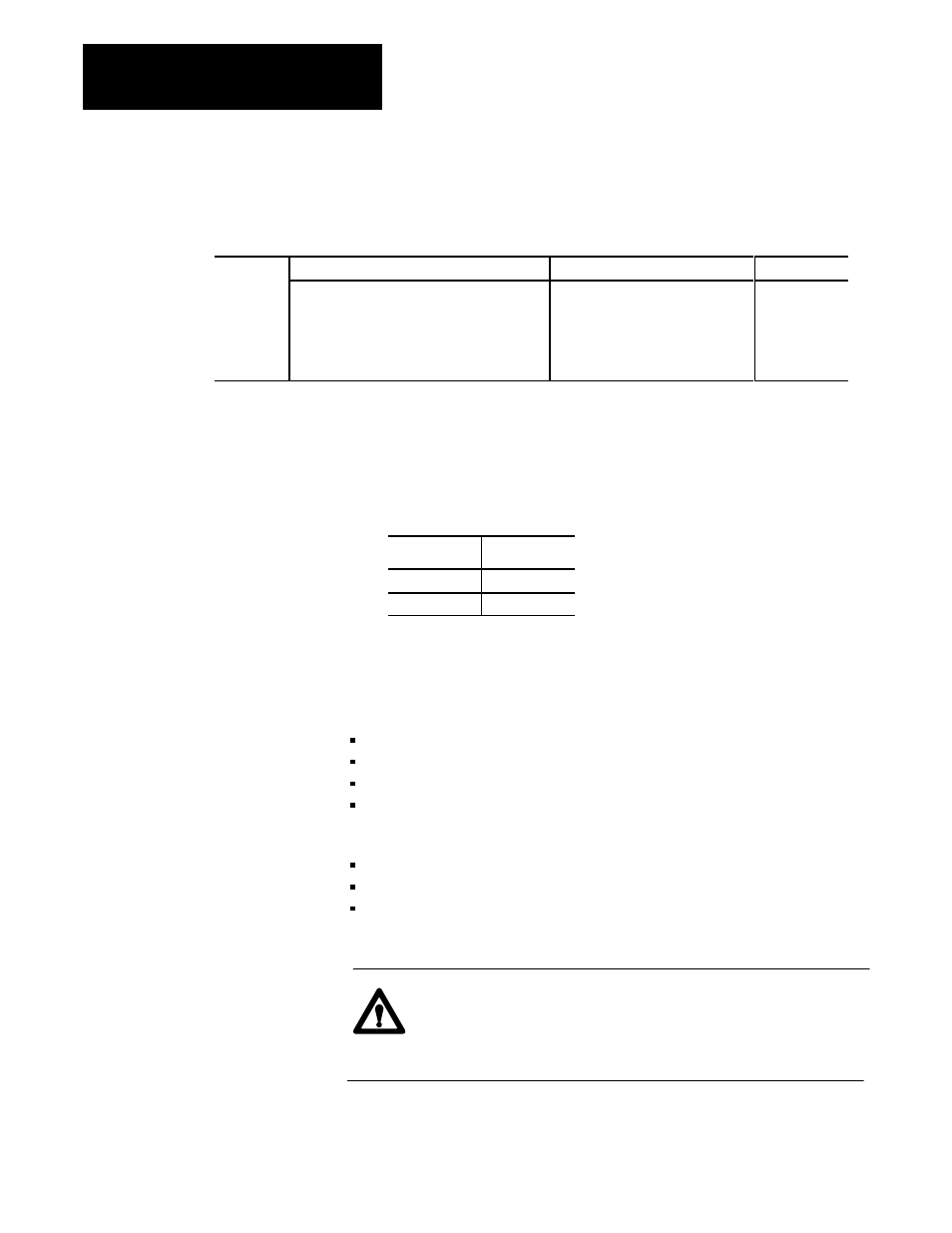

8ĆA

Velocity vs. position algorithm

IPC03ĆB01 = B00 = 0

B38/96, 97

(chapter 8)

Transition setpoints:

Time limit

Ram (screw) position

Ram (screw) pressure

Cavity pressure

Minimum position for pressure transition

IPC60 = above typical

IPC61 = estimated top of cushion

IPC62 = below mold flash pressure

IPC63 = zero to inhibit

IPC64 = zero to inhibit

N44:116

N44:117

N44:118

N44:119

N44:120

Download new values to the QDC module by downloading INC and IPC.

Important: If downloading from your programming terminal, you must

download INC first, followed by IPC (chapter 4).

To download:

Set:

INC

B21/7

IPC

B21/8

Span Your Injection Velocity Valve

Span your injection valve for smooth operation at the highest desired

velocity. Do this by finding optimum values for these words:

Minimum Velocity Control Limit INC45 (N44:41)

Maximum Velocity Control Limit INC46 (N44:42)

Selected Velocity Valve, Output for Minimum INC47 (N44:43)

Selected Velocity Valve, output for maximum INC48 (N44:44)

Important: If PanelView is operational, use it to:

observe

actuals

change and download setpoints

run

profiles

Important:

We suggest that you read this entire procedure before starting.

ATTENTION: As with any machine start-up, make sure you

installed a test mold in the machine. Programming errors,

configuration errors, or hydraulic problems could lead to

machine damage or injury to personnel.