Rockwell Automation 1771-QDC, D17716.5.85(Passport) MNL. PLASTIC MOLDING MODULE User Manual

Page 163

Tune Your Machine for Producing Parts

Chapter 10

10-17

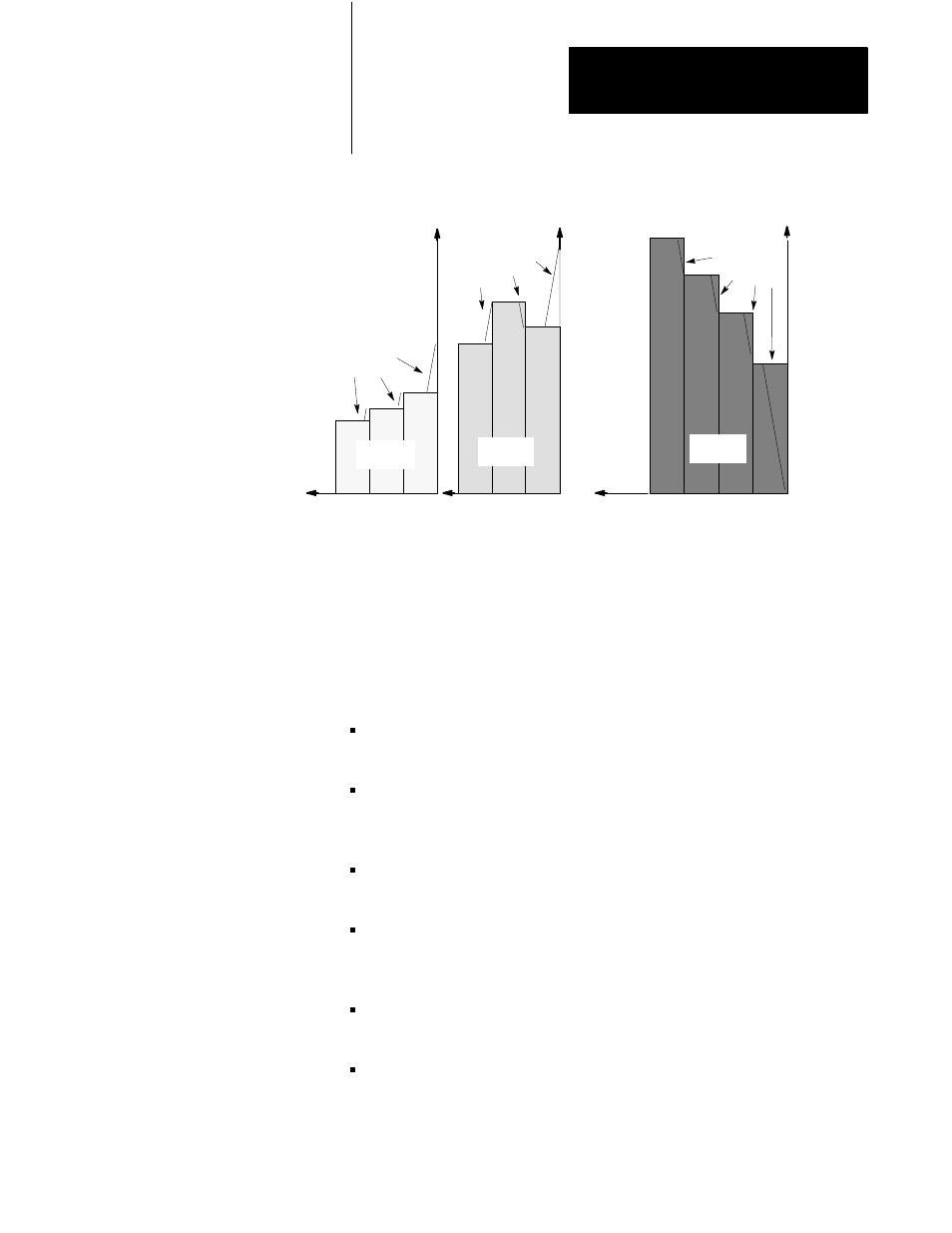

Figure 10.1

Example Injection, Pack, and Hold Profiles with Accl/Decel Ramps

Time

Selected

Valve

Decel Ramps

Selected Valve

Accel & Decel.

Ramps

Selected

Valve

Accel. Ramps

Hold

Profile

Pack

Profile

Injection

Profile

Pressure

Velocity

Position

Important: When enabled, the QDC module applies ramp rates at the

beginning of each profile segment. When moving from one profile to the

next, the QDC module never applies ramps until it begins the next profile.

With caution, you can use ramp rates to smooth out jerky motion present

during large increases or decreases in pressure or flow.

If your application requires the use of ramp rates:

Never apply ramp rates until you have already tuned all applicable

pressure and velocity loops.

Ramp rates control selected and unselected valves. Therefore, even

though you may be controlling velocity, you can ramp ram (screw)

pressure during an injection profile prior to pack.

Ramp rates and ERC may not function properly together. Be very

careful if applying ERC and ramp rates on the same profile.

Using slow ramp rates may force pressure and velocity actuals out of

control because these actuals include the time spent ramping as well as

the time for each segment.

The QDC module uses ramp rates when beginning a profile or

movement, or when stepping from segment to segment within a profile.

You enter ramp rates in units of 0 to 9999 percent signal output per

second (note that there is no decimal point). A ramp rate of 9999 lets

the output move full range in 10 milliseconds, while a ramp rate of 99

requires a full second to go full range. Lower values = slower ramps.