Rockwell Automation 1771-QDC, D17716.5.85(Passport) MNL. PLASTIC MOLDING MODULE User Manual

Page 46

Enter Your SWTL Configuration Values Here

Configure the QDC Module's I/O

Chapter 3

3-15

ignores all profile commands (except set-outputs and jogs) until you jog

the cylinder back through the deadband into the safe zone at either end

The deadband guards against sensor noise flickering the SWTL alarms and

requires the operator to jog the cylinder a set distance away from the

software overtravel. We recommend a value of 00.10 inch as a starting

deadband. Your sensor may require a greater deadband.

ATTENTION: The QDC module ignores SWTL alarms when

jogging or when performing a set-output operation.

Configure the QDC module for SWTL as follows:

1.

Determine these SWTL values for ram (screw) travel with respect to

the range of physical travel.

SWTL deadband

Maximum SWTL

Minimum SWTL

2.

Record non-zero SWTL values on Worksheet 3-F. Zero values

disable the corresponding SWTLs.

ATTENTION: Leaving your SWTL settings at zero (MCC13

and 14), inhibits the QDC module from performing this safety

function.

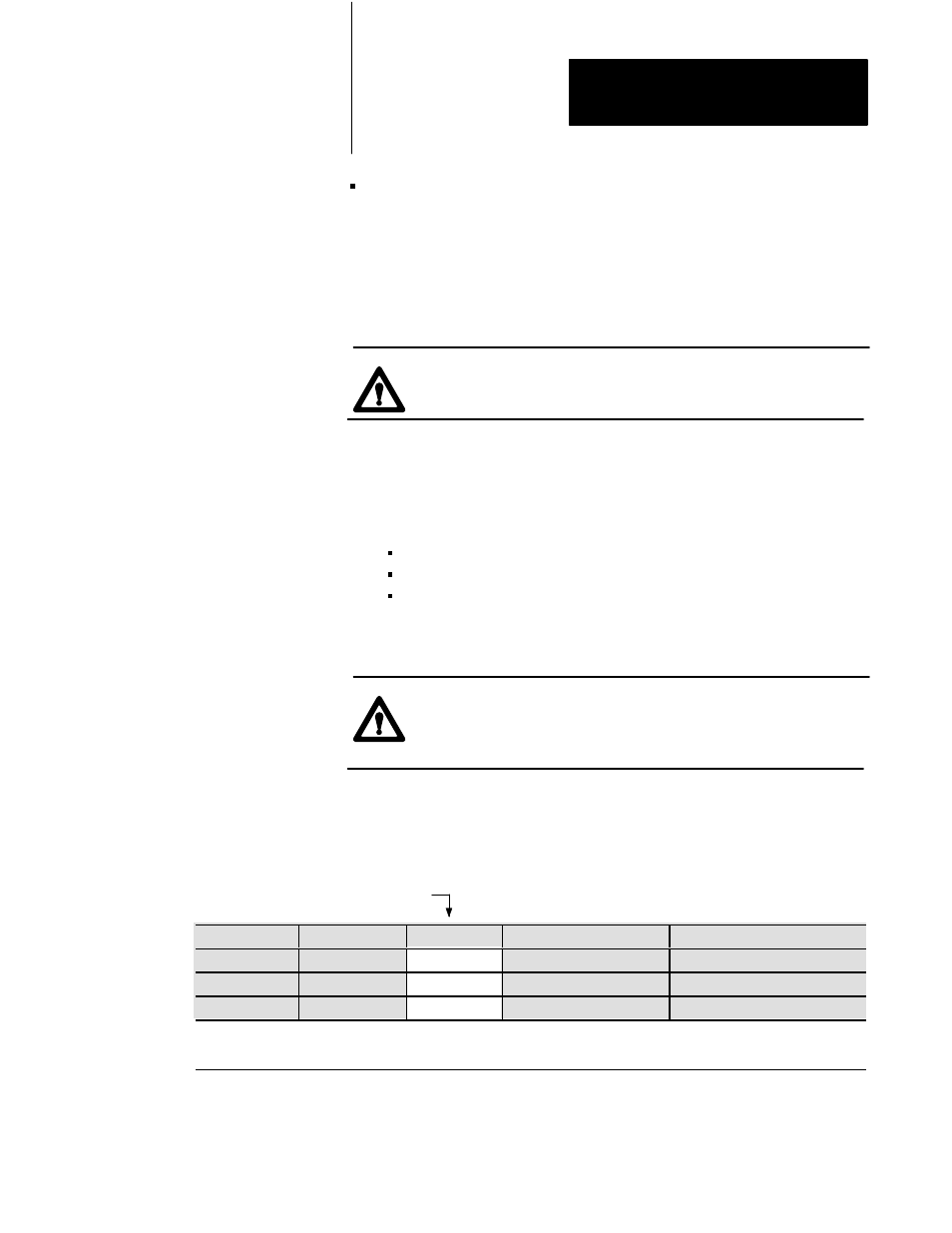

Worksheet 3ĆF

SWTL Configuration Values

Control Word

ProĆSet 600 Addr. Value

Description

Units

MCC13

N40:9

Screw Minimum SWTL

Screw Axis Measured from zero

1

MCC14

N40:10

Screw Maximum SWTL

Screw Axis Measured from zero

1

MCC15

N40:11

10

Screw SWTL Deadband

As noted

1

1

Incremental Distance

00.00 to 99.99in

000.0 to 999.9mm

You may now download your adjusted values using the MCC download

procedure presented earlier in this chapter.