Span your injection pressure valve, Span your valves chapter 9, Confirm critical values – Rockwell Automation 1771-QDC, D17716.5.85(Passport) MNL. PLASTIC MOLDING MODULE User Manual

Page 119

Span Your Valves

Chapter 9

9-2

We recommend that you first span your injection pressure valve for

optimum pressure performance. You do this in four parts:

Confirm critical values

Span your injection pressure valves

Test valve linearity with a pressure vs. time injection profile

Set profile pressure alarms

Important: You may omit the subsection Span Your Injection Pressure

Valve below if you have information from molding machine OEMs or

hydraulic valve manufacturers on spanning the working range of valves. If

available for your machine’s injection pressure valve(s), enter valve

spanning values into pressure control limits INC41-44 and proceed to Test

Valve Linearity. First confirm your critical values.

Confirm Critical Values

Important: Confirm that all values you recorded for configuration

(chapter 7) and profiles (chapter 8) are as follows:

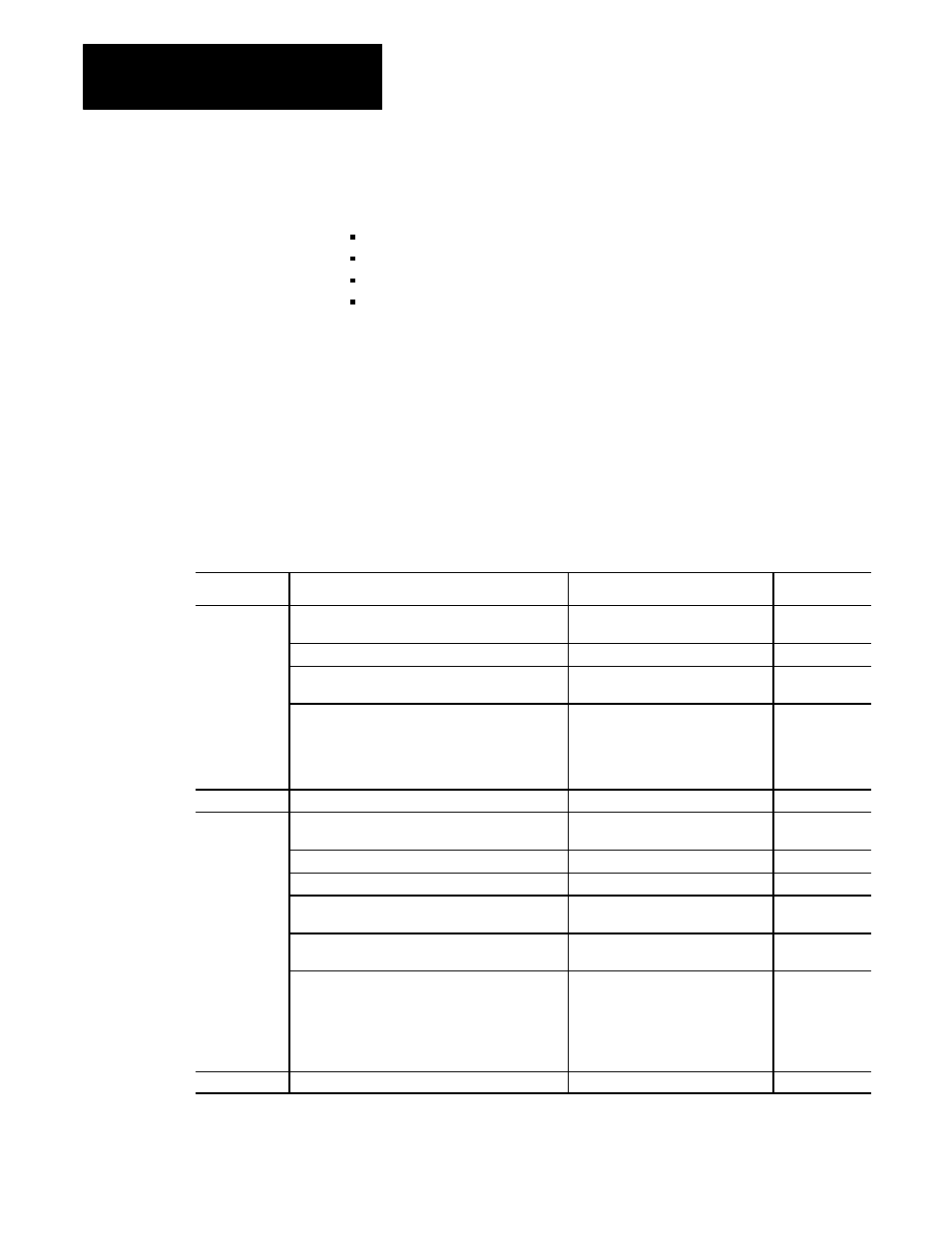

On Worksheet Confirm Your Configuration

With These Words or Bits

ProĆSet Addr.

7ĆA

(chapter 7)

QDC module output to which you connected your

pressure control valve

INC02ĆB06, B05, B04

B38/20, 21, 22

SetĆoutput values for unselected valves

INC09Ć12 = your values

N44:5, 6, 7, 8

All ramping is disabled with zero ramp rates

INC17Ć20 = 0

INC25Ć28 = 0

N44:13Ć16

N44:21Ć24

Pressure limits:

Minimum Pressure Control Limit

Maximum Pressure Control Limit

Selected Pressure Valve, Output for Minimum

Selected Pressure Valve, Output for Maximum

INC41 = 0

INC42 = system pressure

INC43 = your value

INC44 = your value

N44:37

N44:38

N44:39

N44:40

7ĆC

EndĆofĆprofile setĆoutput values

HDC33Ć36 for zero output

N44:209Ć212

8ĆA

(chapter 8)

Pressure vs Time algorithm

IPC03ĆB01 = B00 = 1

B38/96Ć97

OpenĆloop control

IPC04ĆB03 = B02 = B01 = B00 = 1

B38/112Ć115

Expert Response Compensation (ERC) is disabled

IPC04ĆB11 = B10 = B09 = B08 = 1

B38/120Ć123

Pressure setpoints

IPC10,14,18,22,26,30,34,38,42,46,50

all equal to oneĆhalf system pressure

start @ N44:66

end @ N44:106

Time setpoints

IPC12,16,20,24,28,32,36,40,44,48

all equal to 1 second (100)

start @ N44:68

end @ N44:104

Transition setpoints

Time limit

Ram (screw) position

Ram (screw) pressure

Cavity pressure

Minimum position for pressure transition

IPC60 = 10 seconds (1000)

IPC61 = zero to inhibit

IPC62 = zero to inhibit

IPC63 = zero to inhibit

IPC64 = zero to inhibit

N44:116

N44:117

N44:118

N44:119

N44:120

8ĆB

Logical bridge to stop and set outputs

HPC03ĆB08 = 1

B38/296

If these are not your current values, we suggest that you correct them now

using the download procedure discussed in chapter 4.

Span Your Injection

Pressure Valve