Determine initial sensorćconfiguration values, Configure the qdc module's i/o chapter 3 – Rockwell Automation 1771-QDC, D17716.5.85(Passport) MNL. PLASTIC MOLDING MODULE User Manual

Page 35

Configure the QDC Module's I/O

Chapter 3

3-4

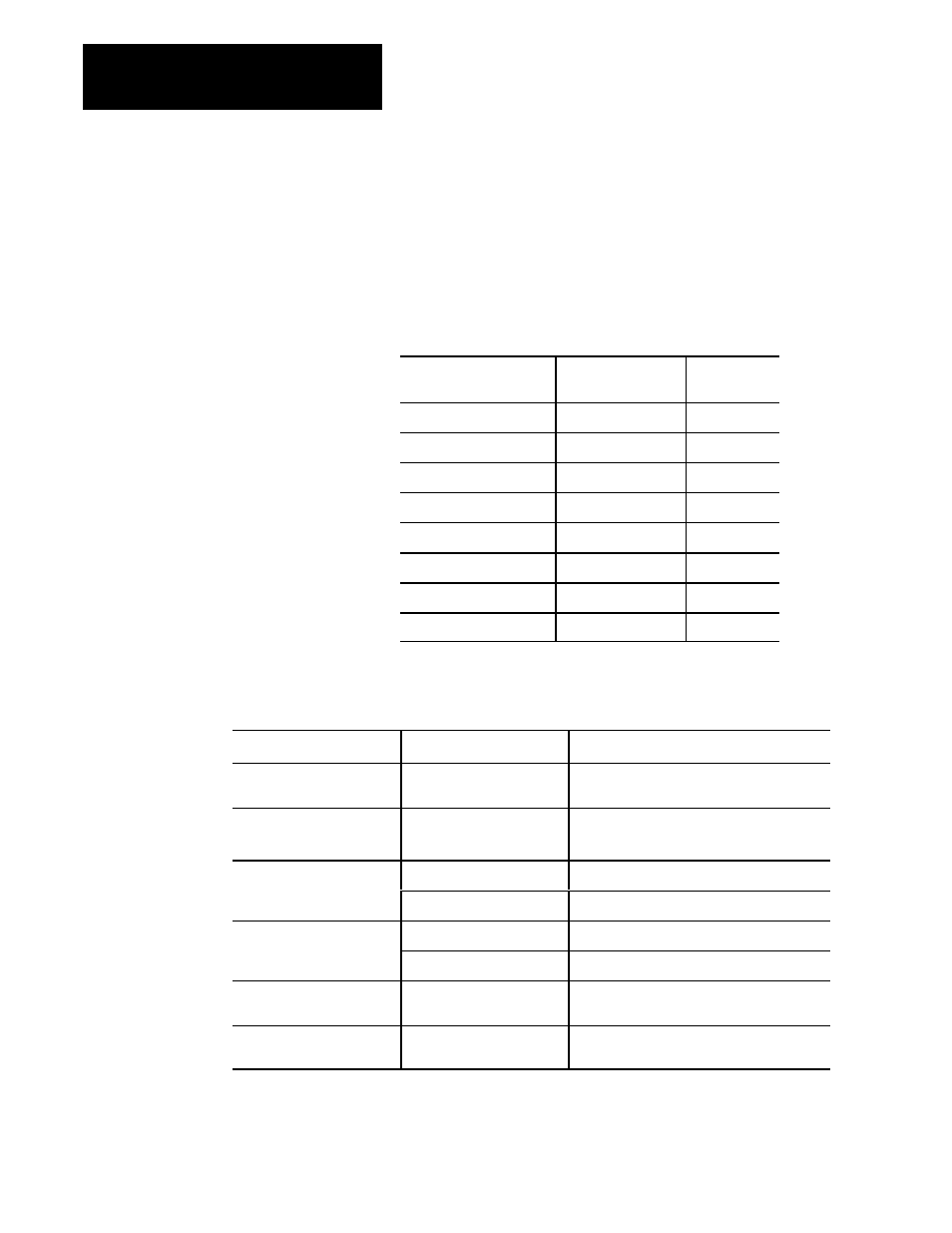

To determine initial sensor configuration values, refer to Table 3.A and

specifications that accompanied your sensors, valves, and cylinders. Write

down applicable values on Worksheet 3-D.

Important: You must enter floating-point numbers and percentages as

integers, so we recommend that you write them in Worksheet 3-D in the

following format: Use an assumed decimal point position that depends on

the range value. For example:

If the Range is:

And You Want to

Enter this Value:

Use this

Format:

0 Ć 099.99%

75%

07500

0 Ć 99.99 inch

7.32 inch

00732

0 Ć 0999.9 mm

432.6 mm

4326

4.00 Ć 020.00 mA

16mA

01600

0 Ć 010.00 vdc

5.6 vdc

00560

0 Ć 009.99 sec

0.47 sec

00047

0 Ć 09999 psi

321 psi

00321

0 Ć 0999.9 Bar

222 Bar

2220

Table 3.A

Determine Initial SensorĆconfiguration Values for Worksheet 3ĆD

Category:

If your:

Then Use a Value Equal to:

Minimum Position

(Line 1)

N/A

zero

Maximum Position

(Line 2)

ram (screw) is fully extended

to the mold end (ram bottom)

full travel of the sensor

Analog Signal @ Min Position sensor is forwardĆacting

low end of your selected range

(Line 3) sensor is reverseĆacting

high end of your selected range

Analog Signal @ Max Position sensor is forwardĆacting

high end of your selected range

(Line 4) sensor is reverseĆacting

low end of your selected range

Minimum Pressure

(Lines 5 and 13)

N/A

minimum range value specified by the

manufacturer

Maximum Pressure

(Lines 6 and 14)

N/A

maximum range value specified by the

manufacturer

Determine Initial

SensorĆconfiguration Values