8ć16 – Rockwell Automation 1771-QDC, D17716.5.85(Passport) MNL. PLASTIC MOLDING MODULE User Manual

Page 111

PPC Block Identifier

Open/Closed Loop

0 = Closed 1 = Open

Enable/Disable ERC

0 = On 1 = Off

Bit 00 for Pressure/Position

Bit 01 for Pressure/Time

Bit 02 for RPM/Position

Bit 03 for RPM/Time

Bit 08 for Pressure/ Position

Bit 09 for Pressure/Time

Bit 10 for RPM/Position

Bit 11 for RPM/Time

Sign of Profile Offset

0 = Positive 1 = Negative

Plastication/PostĆdecompression

Logical Bridging

0 = Start PostĆdecomp Movement

1 = Stop and set outputs

Profile Algorithm

00 = Ram (screw) Pressure/Position

01 = Ram (screw) Pressure/Time

10 = Screw RPM/Position

11 = Screw RPM/Time

Bit 12 for RPM Profile

Bit 13 for Pressure Profile

Code:

Your value

Required initial value

loaded by ProĆSet 600

0 or 1

Load Initial Profile Values

Chapter 8

8-16

Use Worksheet 8-C to enter setpoints for a backpressure vs. position

plastication profile. The valve spanning procedures in chapter 9 require

specific values. We have already entered many values for you, and help

you determine other values in the text that follows.

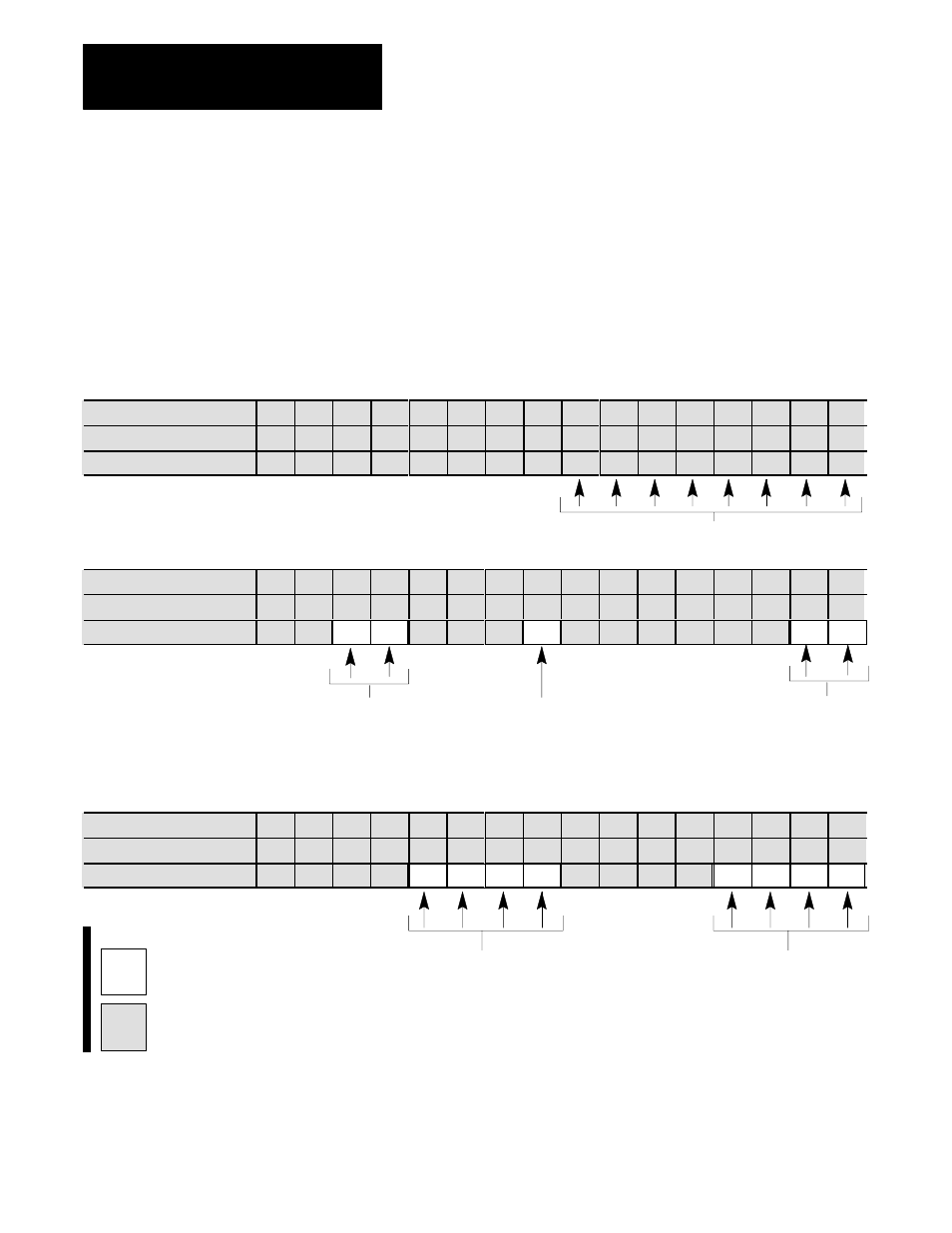

Worksheet 8ĆC

Plastication Profile Block (PPC)

Control Word PPC01ĆBxx

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

00

ProĆSet 600 Addr. B38/bit

463 462 461 460 459 458 457 456 455 454 453 452 421 450 449 448

Value

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

Control Word PPC03ĆBxx

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

00

ProĆSet 600 Addr. B38/bit

495 494 493 492 491 490 489 488 487 486 485 484 483 482 481 480

Value

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

Control Word PPC04ĆBxx

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

00

ProĆSet 600 Addr. B38/bit

511 510 509 508 507 506 505 504 503 502 501 500 499 498 497 496

Value

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

Determine and Record

Setpoints

for Plastication Profile (PPC)