Configure the qdc module's i/o chapter 3 – Rockwell Automation 1771-QDC, D17716.5.85(Passport) MNL. PLASTIC MOLDING MODULE User Manual

Page 47

Enter Your Alarm and TimeĆdelay Values Here

Configure the QDC Module's I/O

Chapter 3

3-16

Set Up Maximum RPM and Pressure Alarms, and Time Delays

The QDC module continuously monitors screw RPM, ram (screw)

pressure, and cavity pressure inputs. When it detects that the process input

equals or exceeds a preset alarm setpoint, the QDC module sets an alarm

bit. A setpoint of zero disables the associated alarm.

To guard against nuisance alarms caused by noise spikes or pressure

transients , you can set a time delay so the QDC module must monitor

continuous excessive pressure or RPM for an amount of time before setting

the high alarm. A setpoint of zero disables this delay.

Configure the QDC module for pressure and RPM alarms as follows:

1.

Determine these values for ram (screw) and/ or cavity pressure

alarms:

pressure-alarm setpoint

time-delay setpoint

2.

Determine these values for screw RPM alarms:

RPM-alarm setpoint

time-delay setpoint

3.

Record non-zero setpoints on Worksheet 3-G for the pressure alarms,

RPM alarm, and time delays you want to use.

4.

Download them to the QDC module using the procedures presented

earlier in this chapter:

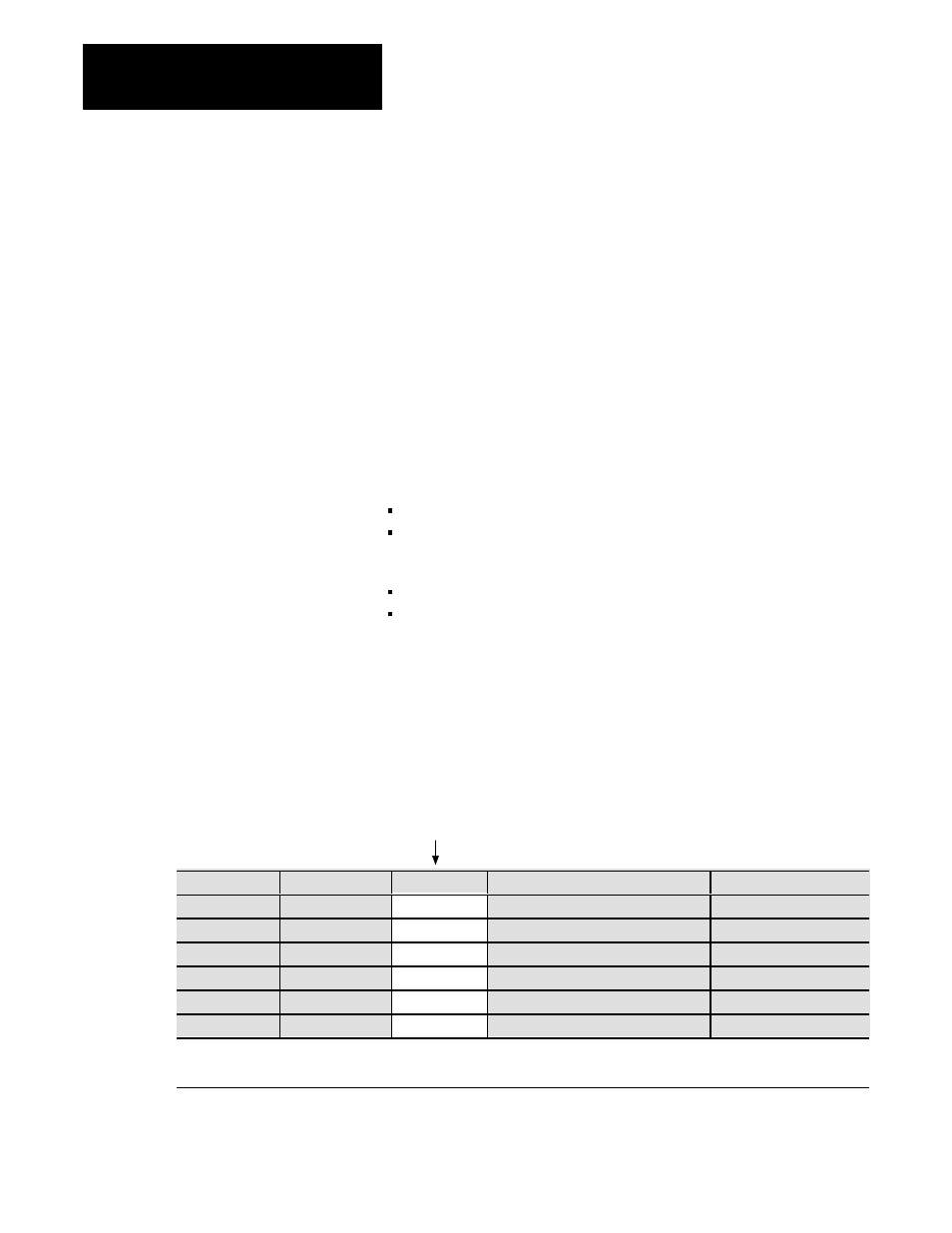

Worksheet 3ĆG

Alarm and TimeĆdelay Setpoints

Control Word

ProĆSet 600 Addr.

Value

Description

Units

MCC21

N40:17

Screw PressureĆalarm Setpoint

Ram (screw) Pressure

2

MCC22

N40:18

ScrewĆpressure TimeĆdelay Setpoint

Time Measured in Seconds

1

MCC55

N40:51

HighĆRPM Alarm Setpoint

Rotational Speed

3

MCC56

N40:52

Screw RPM TimeĆdelay Setpoint

Time Measured in Seconds

1

MCC61

N40:57

Cavity PressureĆalarm Setpoint

Cavity Pressure

4

MCC62

N40:58

CavityĆpressure TimeĆdelay Setpoint

Time Measured in Seconds

1

1

Time Measured in Seconds

2

Pressure

3

Rotational Speed

4

Pressure

00.00 to 00.99

0000 to 9999 PSI

000.0 to 999.9 RPM

00000 to 20,000 PSI

000.0 to 999.9 Bar

0000.0 to 2000.0 Bar