11ć2, Module calibration, Troubleshoot with leds chapter 11 – Rockwell Automation 1771-QDC, D17716.5.85(Passport) MNL. PLASTIC MOLDING MODULE User Manual

Page 169

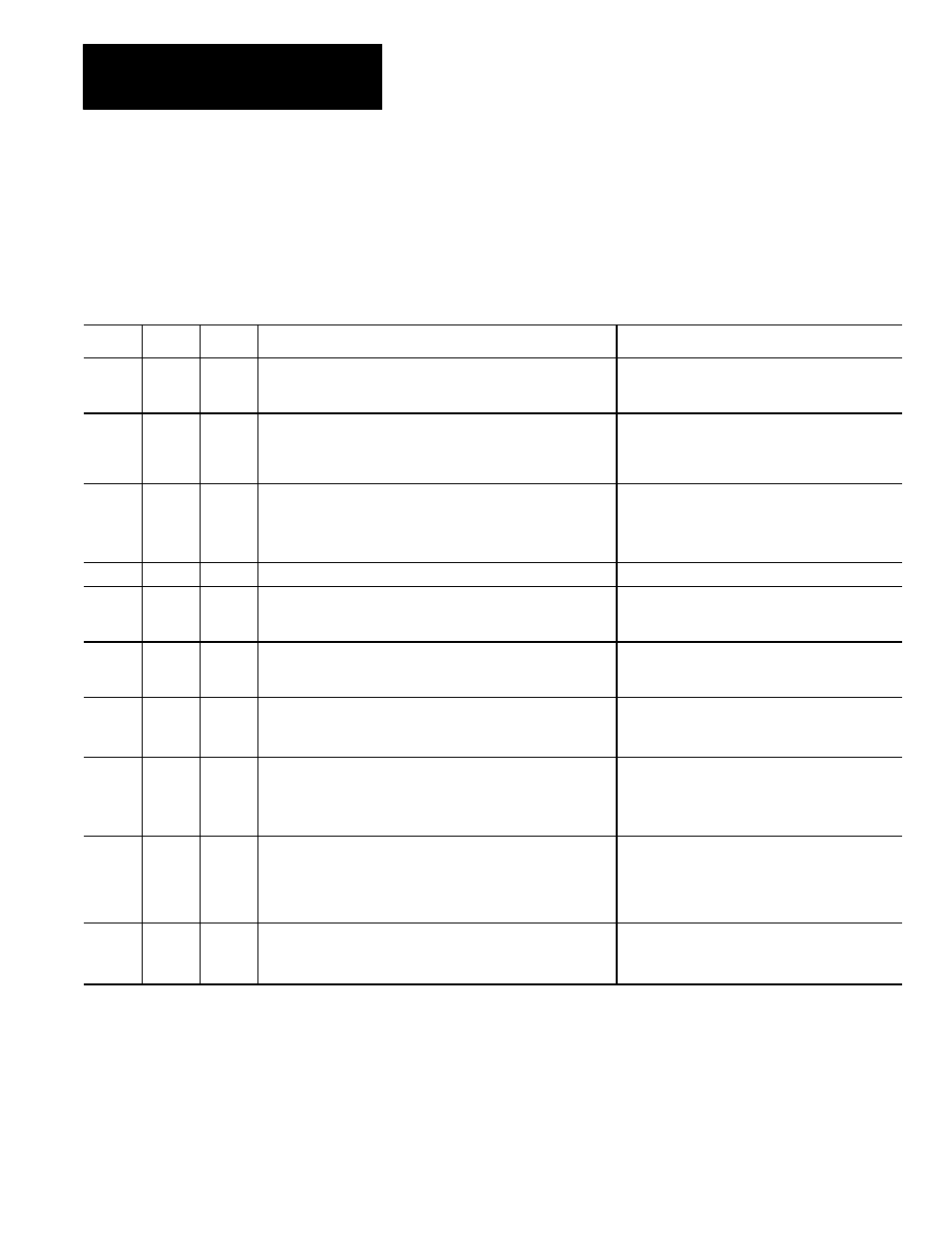

Troubleshoot with LEDs

Chapter 11

11-2

Table 11.A shows how to interpret QDC module LEDs. The QDC module

monitors its own operation and reports detected conditions by illuminating

its LEDs in the following combinations:

Table 11.A

LED Indicator Conditions

ACTIVE FAULT

COMM

Condition:

We recommend that you:

Flashing Off

Off

PowerĆup. The QDC module has completed its powerĆup diagnosĆ

tics, the QDC module hardware and firmware are OK, and the QDC

module is awaiting download of the MCC block.

Download the MCC block. ProĆSet 600 downloads

the MCC when you switch your PLCĆ5 processor

from program mode to run mode.

Flashing Red

Yellow

Software Error. The QDC hardware and firmware are OK, the last

BTW received by the QDC module had a recognizable block ID, but

the last MCC received by the QDC module contained a programĆ

ming error.

1. Fine and correct the MCC programming error.

2. Use the MCC download procedure in chapter 3

to download corrected data to the QDC module.

Flashing Red

Off

Software Error. The QDC hardware and firmware are OK, but the

last BTW received by the QDC module did not have a recognizable

block ID, and the last MCC received by the QDC module contained

a programming error.

1. Find and correct the MCC programming error.

2. Use the MCC download procedure in chapter 3

to download corrected data to the QDC module.

3. Verify block IDs in your BTW data files.

Flashing Flashing Flashing You put the Run/Calibrate jumper (E1) in the Calibrate position.

Put the E1 jumper in the Run position (chapter 2).

Green

Off

Yellow

Normal operation. The QDC hardware and firmware are OK, no

programming errors exist, and the last command block

received by the QDC module had a recognizable block ID.

Do nothing.

Green

Off

Off

Software Error. The QDC hardware and firmware are OK, no proĆ

gramming errors exist, but the last command block received by the

QDC module did not have a recognizable block ID.

Verify block IDs in your BTW data files.

Green

Red

Yellow

Limited operation. The QDC hardware and firmware are OK, the

last command block received by the QDC module had a recognizĆ

able block ID, but a programming error(s) exists.

1. Find and correct the programming error.

2. Use the download procedure in chapter 4 to

download corrected data to the QDC module.

Green

Red

Off

Software Error. The QDC hardware and firmware are OK, but a

programming error(s) exists, and the last command block

received by the QDC module did not have a recognizable block ID.

1. Find and correct the programming error.

2. Use the download procedure in chapter 4 to

download corrected data to the QDC module.

3. Verify block IDs in your BTW data files.

Off

Off

Flashing Communications Error. The QDC hardware and firmware are OK,

but the module is not completing continuous transmission of status

data blocks to the host PLC processor. The QDC module is inoperĆ

able until continuous BTR communication is reĆestablished with the

host PLC processor.

1. Verify your PLC is in run mode.

2. Reseat your QDC module in the I/O chassis.

3. Check for PLC ladder programming problems.

Off

Red

Yellow

or Off

Hardware fault. The QDC module is inoperable.

1. Cycle power to the QDC module.

2. Replace the QDC module

3. Return it for factory repair.

We recommend that you re-calibrate your QDC module every two years.

To calibrate it yourself, refer to the Reference Manual, 1771-6.5.88 (dated

November 1992), for calibration instructions. Otherwise, return it to the

factory with this order number: 1771-QDC/(Rev Letter) – CAL.

Module Calibration