Contactor maintenance, Removing the contactor, Contactor maintenance removing the contactor – Rockwell Automation 1512B MV Controllers, 200/400A Two-High Cabinet, Standard and Arc-Resistant Enclosure User Manual

Page 60: Refer to, Removing the contactor on

52

Rockwell Automation Publication 1500-UM055G-EN-P - May 2013

Chapter 5

Maintenance

6. Ensure that the flares on the fuse ferrules are properly located with respect

to the fuse clips.

7. Apply a rapid shove to the bottom portion of the fuse barrel to force the

fuse into the clip.

8. Apply a rapid shove to the top portion of the fuse barrel to force the fuse

into the clip.

9. Grip center of fuse barrel with both hands and apply slight back and

forward force to ensure fuse has been properly seated in the fuse clips.

10. Again check and verify that the flares at the top and bottom of the fuse are

not in the contact area of the fuse clip.

11. If interphase barriers were previously removed ensure they are properly

reinstalled.

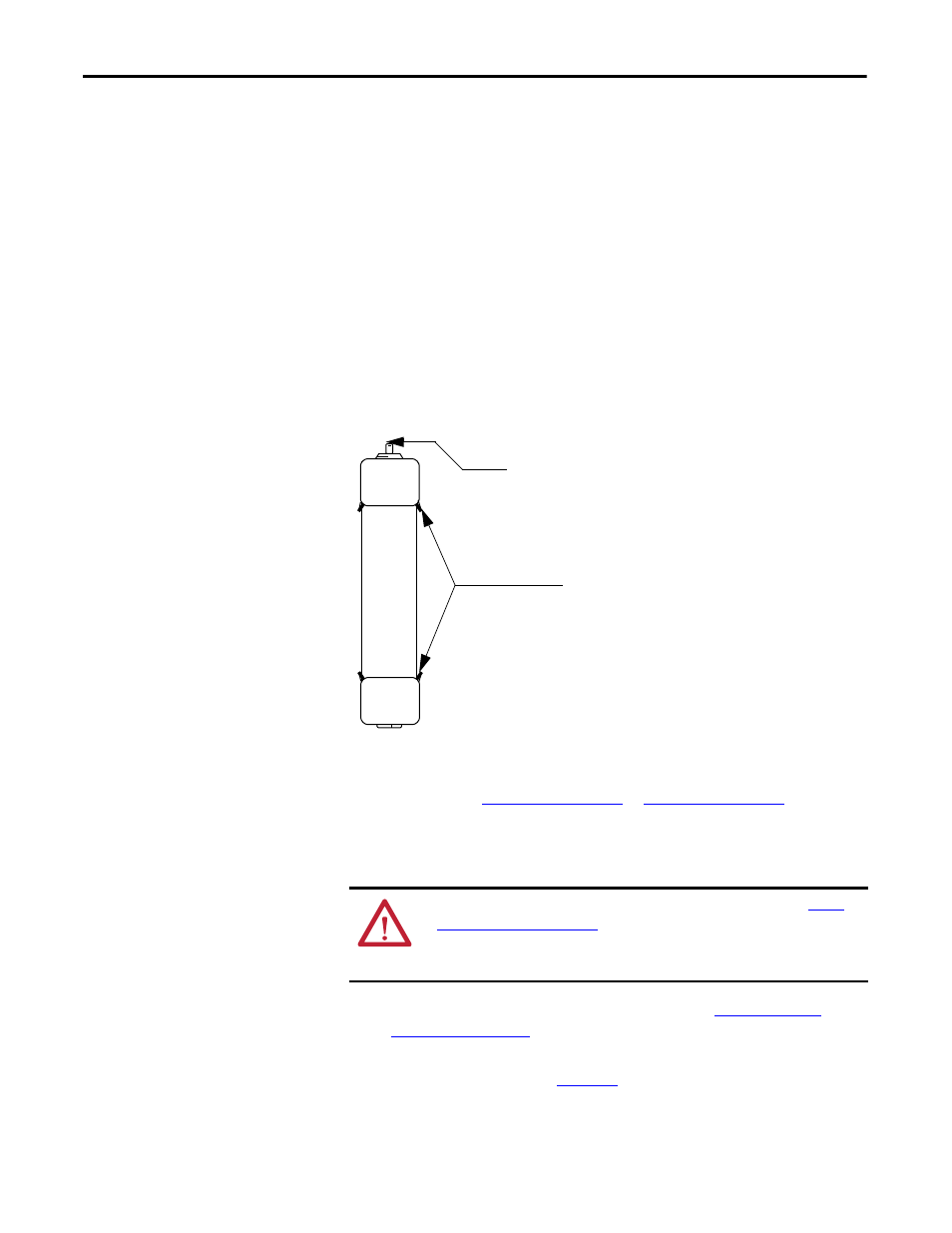

Figure 51 - Clip-on Style Medium Voltage Power Fuse

Contactor Maintenance

Refer to publication

for

contactor maintenance instructions.

Removing the Contactor

1. Complete the Power Lock-out Procedure (refer to

).

2. Disconnect the control wiring harness from the wire plug at the lower left

side of the contactor (See

)

3. Remove the control power transformer primary fuses from the top of the

contactor.

Flares

Blown Fuse Indicator

(shown in blown state)

ATTENTION: To avoid shock hazards, lock out incoming power (refer to

) before working on the equipment. Verify with a

hot stick or appropriate voltage measuring device that all circuits are voltage

free. Failure to do so may result in severe burns, injury or death.