Joining sections, Figure 5 – Rockwell Automation 1512B MV Controllers, 200/400A Two-High Cabinet, Standard and Arc-Resistant Enclosure User Manual

Page 16

8

Rockwell Automation Publication 1500-UM055G-EN-P - May 2013

Chapter 2

Installation – Standard Enclosure

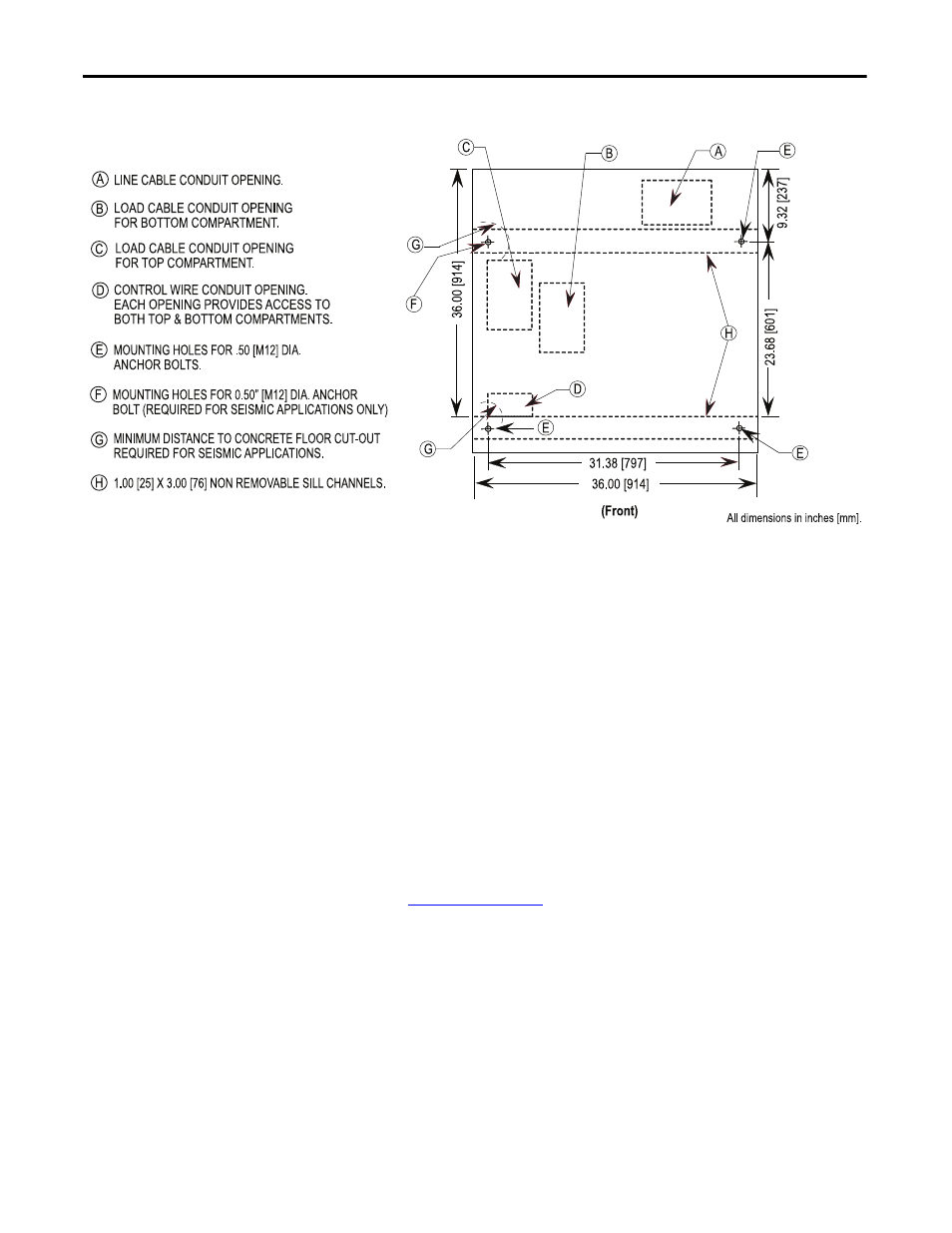

Figure 5 - Cabinet Floor Plan

NOTES FOR SEISMIC APPLICATIONS

• For installations on concrete – the minimum depth and radius of

concrete supporting the cabinet anchors is dependent on seismic loads.

Refer to important information above.

• For installations on a metal structure – the metal plate depth and cabinet

anchoring method is dependent on seismic loads.

Joining Sections

1. Position the left side of the section on a level surface and secure the section

in place with 12 mm (1/2 in. [M12]) floor mounting bolts (refer

to

2. When joining NEMA Type 12, apply a continuous 3 mm (1/8 in.) wide

bead of silicon sealer around the perimeter of one section.

3. Remove the side bus access covers if applicable.

4. Position the right section against the left section. Ensure that the surface is

level.

TIP

Joining hardware can be found in a package mounted on the front of the

shipping skid. Refer to publication MV-QS050_-EN-P for level floor surface

requirements.