Insulated power bus splicing, Figure 38, Figure 39 – Rockwell Automation 1512B MV Controllers, 200/400A Two-High Cabinet, Standard and Arc-Resistant Enclosure User Manual

Page 44

36

Rockwell Automation Publication 1500-UM055G-EN-P - May 2013

Chapter 4

Common Installation

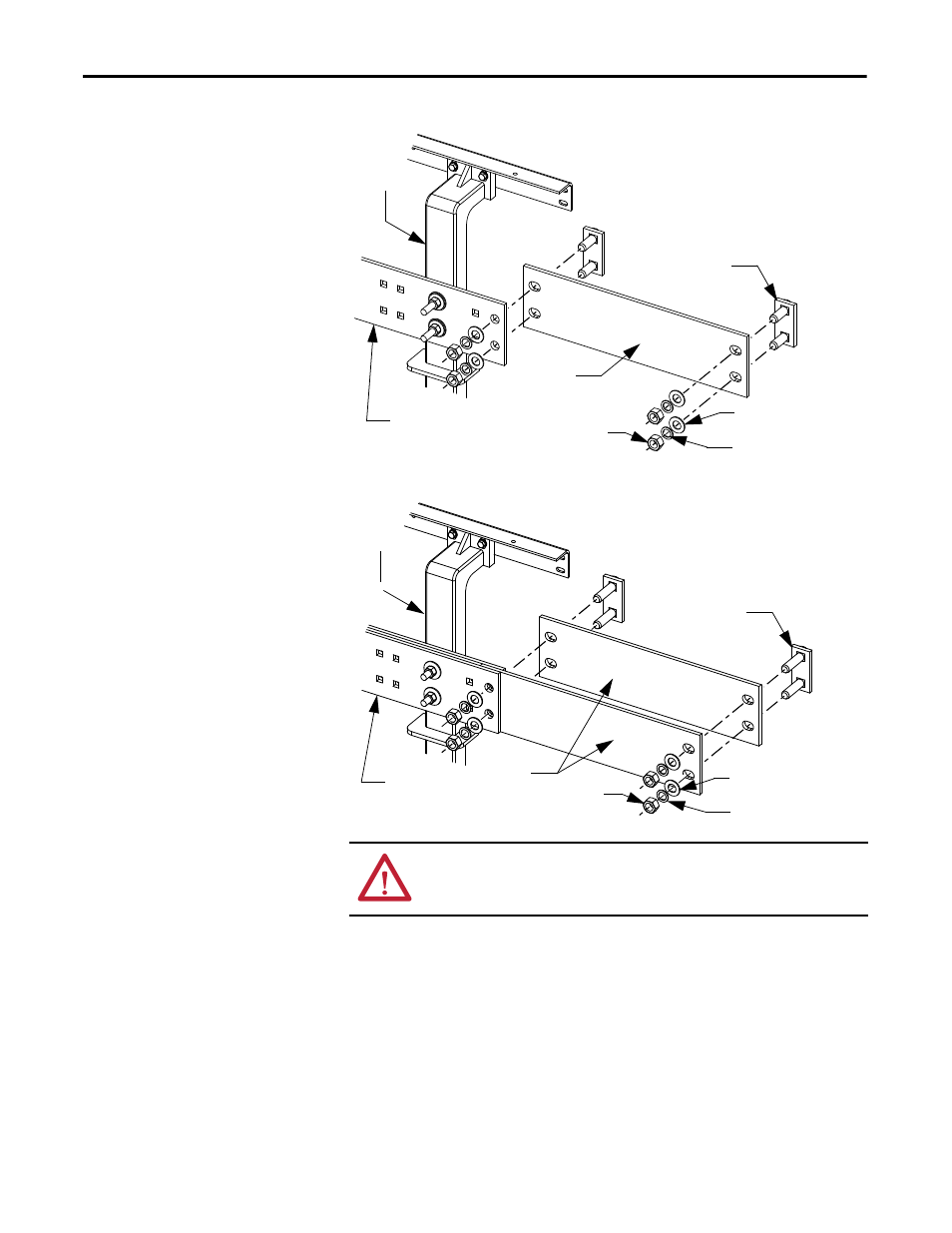

Figure 38 - Typical 1200A Power Bus Splicing Configuration (Viewed from front of cabinet)

Figure 39 - Typical 2000A Power Bus Splicing Configuration (Viewed from front of cabinet)

Insulated Power Bus Splicing

If the starter is equipped with insulated power bus, then a splice kit with insulated

links, insulating boots and tape will be provided. Refer to the kit for installation

instructions.

Bus Clamp

Flat Washer

Lock Washer

Hex Nut

Power Bus

Splice Bar

Bus Support

Main Horizontal

Power Bus

Bus Clamp

Flat Washer

Lock Washer

Hex Nut

Power Bus

Splice Bars

Bus Support

Main Horizontal

Power Bus

ATTENTION: Ensure all barriers are replaced before re-energizing the

equipment. Failure to do so may result in electrical faults and cause damage to

equipment or severe injury to personnel.