Ground bus, Incoming line cable connections – Rockwell Automation 1512B MV Controllers, 200/400A Two-High Cabinet, Standard and Arc-Resistant Enclosure User Manual

Page 45

Rockwell Automation Publication 1500-UM055G-EN-P - May 2013

37

Common Installation

Chapter 4

Ground Bus

to determine the correct ground splice configuration and

assemble as shown.

2. Torque the hardware to 15 N•m ± 1 N•m (12 lb•ft ± 1 lb•ft).

3. Check all hardware for correct tightness and replace all covers and plates.

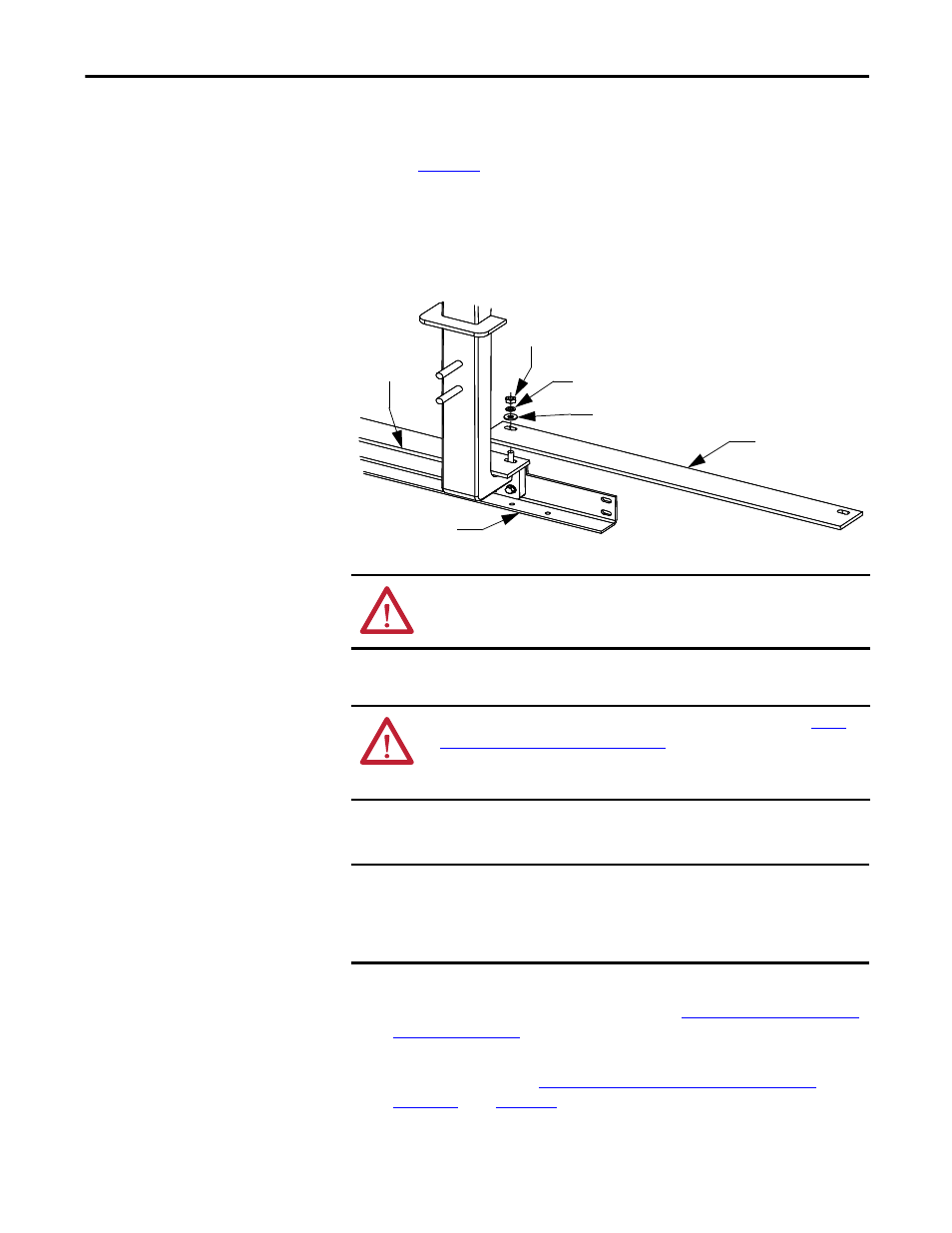

Figure 40 - Typical Ground Bus Splicing Configuration (Front View)

Incoming Line Cable

Connections

Incoming cables are connected to the power bus in the last section on the left.

1. Remove the center-back plate or side plate to access the power bus. If access

to the rear of the unit is not possible, refer to

for either standard or ArcShield enclosures.

2. Connect the incoming power lines to the power bus. Torque to

specifications (refer to

Recommended Torque Values on page 3 of

) (see

).

Ground Bus Support

Main

Ground

Bus

Hex Nut

Lock Washer

Flat Washer

Ground Bus Splice Bar

ATTENTION: Ensure all barriers are replaced before re-energizing the

equipment. Failure to do so may result in electrical faults and cause damage to

equipment or severe injury to personnel.

ATTENTION: To avoid shock hazards, lock out incoming power (refer to

Lock-out Procedure on page 47 of Chapter 5

) before working on the equipment.

Verify with a hot stick or appropriate voltage measuring device that all circuits

are voltage free. Failure to do so may result in severe burns, injury or death.

IMPORTANT

For Non-ArcShield units, cable size should not exceed 1-750 MCM or

2-500 MCM per phase.

For ArcShield units, cable size should not exceed 1-500 MCM or 2-4/0 per

phase. For larger cables, an incoming line module must be used.