Care and use manual – Waters BioSuite Columns User Manual

Page 3

[ Care and Use ManUal ]

BioSuite Columns

3

the flow in this reversed flow direction until a few drops of mobile phase

exit from the column. Turn off the flow, let the pressure go to zero, and

disconnect the column from the system. Turn the column around and hook

it up so that the flow is now in the direction of the arrow. Start the flow

at a low setting and stop it as soon as the mobile phase exits from the

bottom fitting. Now you can hook up the column to the detector inlet and

increase the flow to the desired setting.)

• Be sure to set the flow within the recommended range shown in the

following tables.

Sample

If possible, always dissolve your sample in mobile phase or the starting

mobile phase when operating under gradient conditions. Alternatively, try

to match the pH, salt concentration and organic solvent of the sample with

those of the mobile phase and run a test to ensure that no precipitate, sus-

pension or flocculate is formed. Finally, before making an injection, filter the

sample through a 0.20-0.45 µm porosity membrane.

III. Waters BIosuIte Pc

18

and PPhenyl rPc columns

This section contains recommended operating conditions and specifications

for the Waters polymer-based, C

18

and phenyl reversed-phase columns.

Operating Conditions

1. Shipping Solvent: 70% Methanol - 30% Water

2. Recommended Operating Flow Rates/Max Pressure:

Note: When using a high viscosity buffer and ambient temperature, the maxi-

mum flow rate may have to be reduced to avoid exceeding the maximum

recommended operating pressure for the column. When changing solvents,

use 50% of the maximum flow rate (20% for the 21.5 mm i.d. preparative

column).

3. Recommended pH Range: 2 - 12 (Avoid extended operation at pH >

10 to maximize column life.)

4. Recommended Organic Concentration Range: 0 - 100% (Note:

Reduced organic concentrations may be required if buffers are present

in the eluent in order to avoid salt precipitation.)

5. Recommended Temperature Range: 5 - 50 °C (Note: Reduce flow rate

when operating at low temperatures (e.g.. 5 C) to avoid excessive

column pressure.)

6. Recommended Cleaning Solvents/Procedures:

A) Acetonitrile or Methanol, or

B) Aqueous buffer in organic solvent, or

C) 0.1 - 0.2M NaOH, or

D) 20 - 40% acetic acid in HPLC grade water.

Clean the column regularly with any of the listed solvents. Cleaning

solvents (C) and (D) can be injected onto the column in 250 µl incre-

ments for a total of one column volume. Use proportionally larger

volumes for the 21.5 mm i.d. prep column. Following use of cleaning

solvent, rinse the column with 3 to 5 column volumes of HPLC grade

water before storage.

7. Recommended Storage: For overnight storage, continuously flush the

column with the mobile phase at 10 - 20% of the maximum recom-

mended flow rate. Store the column in the shipping solvent when the

column will not be used within 48 hours.

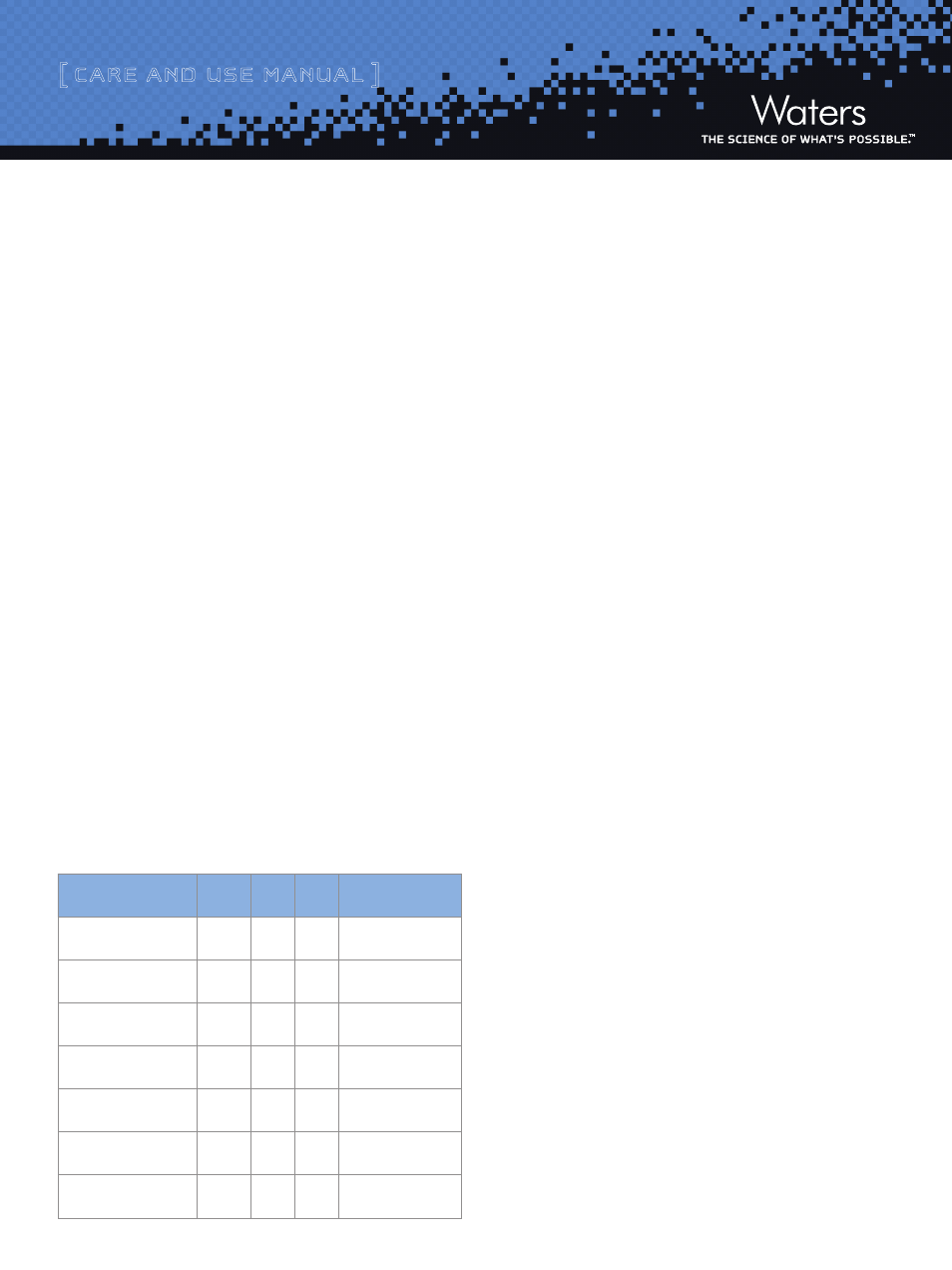

Description

Matrix

i.d.

(mm)

L

(mm)

Flow Rates / Max

Pressure

BioSuite pC

18

, 2.5 µm

NP RPC

polymer

4.6

35

1.0 - 1.6 mL/min /

3000 PSI

BioSuite pC

18

, 500,

7 µm RPC

polymer

4.6

150

0.08 - 0.22 mL/min

/ 1500 PSI

BioSuite pC

18

, 500,

7 µm RPC

polymer

4.6

150

0.5 - 1.2 mL/min /

1750 PSI

BioSuite pC

18

, 500,

13 µm RPC

polymer 21.5

150

3.0 - 8.0 mL/min /

500 PSI

BioSuite pPhenyl, 1000,

10 µm RPC

polymer

2.0

75

0.05 – 0.12 mL/min

/ 150 PSI

BioSuite pPhenyl, 1000,

10 µm RPC

polymer

4.6

75

0.5 - 1.2 mL/min /

450 PSI

BioSuite pPhenyl, 1000,

13 µm RPC

polymer 21.5

150

6.0 - 8.0 mL/min /

450 PSI