Care and use manual, Xi. warrant y, Xii. ordering information – Waters Dextro-Pak Cartridge User Manual

Page 7

[ Care and Use ManUal ]

Dextro-Pak Cartridge

7

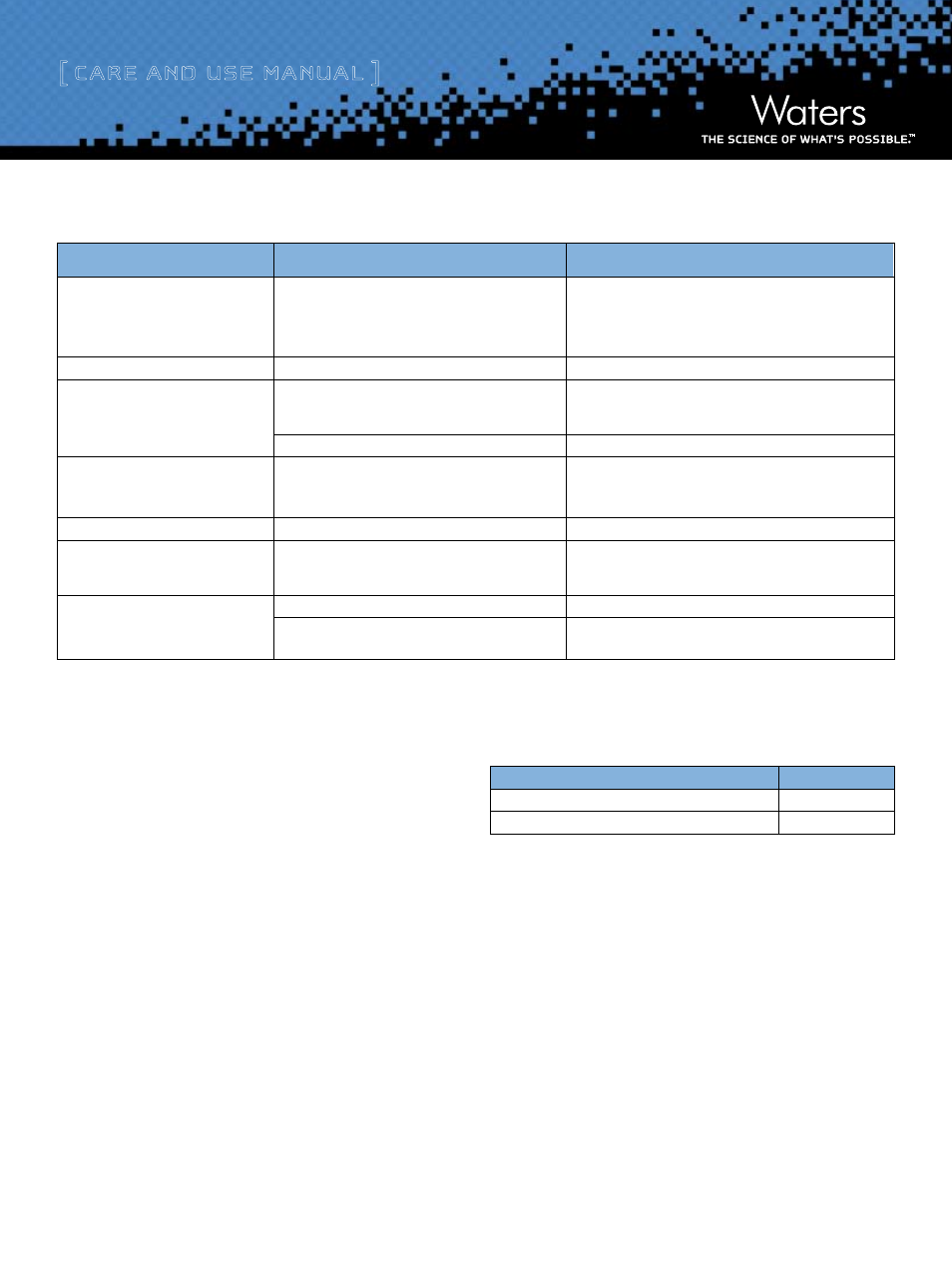

Table Troubleshooting Procedures

XI. warrant y

Waters warrants its high-performance liquid chromatography

cartridges in accordance with the following terms and conditions:

Waters will repack or replace (at our discretion) without cost, any

cartridge that fails to perform satisfactorily if notified within 60 days

from receipt of the cartridge. Any cartridge returned must have a

prior Return Authorization Number assigned by the Waters Customer

Service Department. Approval is subject to the following exclusions:

•

Physical damage to the cartridge because of misuse or abuse.

•

Chemical damage to the packing material because of use with

incompatible solvents or buffers, or at an incorrect pH.

• Physical damage to the packing material because of opera-

tion at incorrect temperatures or pressures.

•

High internal pressures which have occurred in the cartridge

due to the improper solvent or sample filtration practices

causing particulate buildup or precipitation in the cartridge or

end fittings due to high internal pressures which have occurred

because of improper solvent or sample filtration practices.

XII. orderIng InformatIon

Problem

Cause

Solution

Excess pressure buildup

In-line filters lugged with particulates

Replace the in-line filter or shut off the pump. When inlet pressure has

dropped to zero, disconnect the in-line filter from the cartridge and

backflush the prefilter only with mobile phase at 9 ml/min until the

particulates are backflushed out.

Excess pressure buildup

Guard column clogged with particles or adsorbed materials

Replace spent guard column with fresh packing.

Fluctuating backpressure

Cartridge inlet frit plugged with particulates.

Always use an in-line filter or guard column to prevent this. Reverse

cartridge to try to wash out particulates at normal flow rate.

Gas in mobile phase

Check degassing procedure.

“Spurious” peaks, not due to sugars

Faulty pump operation Elution of salts and/or acids

Keep mobile phase heated to 70 °C. Inspect pump check valves and

carry out “Ramp Test” (consult the operator’s manual for your pump).

Check sample cleanup procedures.

Leaking mobile phase

Fittings in bad state

Tighten fittings properly.

Variable elution times of repair

Variations in flow rate

DO NOT OVERTIGHTEN. Replace worn fittings,o-rings, or seals. Check

system for faults, leaks, especially pulsations from pump.

Band broadening or loss of resolution

Guard column fouled

Replace spent guard column with fresh packing.

Analytical cartridge fouled or old

Try washing with 20% acetonitrile, 80% water. If cartridge does not

recover, use a new cartridge.

Item

Part Number

Compression screws and ferrules (5 pk)

WAT025604

Guard-Pak~” Inserts Resolve”’ C1e (10 pk)

WAT085824