Care and use manual – Waters Amino Acid Analysis Liquid Chromatography Column User Manual

Page 4

[ Care and Use ManUal ]

4

III. column care & use consIderatIons

a. column care considerations

• ALWAYS filter samples to prevent excessive pressure buildup due to

particulate matter. Use a Sample Clarification Kit (Part No. 26865)

and, if necessary, centrifugation. For more details on the Waters

Sample Clarification Kit call or write for Bulletin D97.

• ALWAYS filter buffers to remove microparticulate matter. This

eliminates high pressures from plugged frits and also helps ensure

long column life. Use a Solvent Clarification Kit (Part No. 85113)

to filter solvents. Vacuum filtration or sonification may be used to

remove dissolved gasses which could affect your solvent delivery

system. For more details on the Waters Solvent Clarification Kit call

or write for Bulletin D97.

• ALWAYS use high purity solvents such as Waters solvents. For ana-

lytical work choose high quality Waters solvents. For more details

on Waters solvents call or write for Bulletin M10.

• ALWAYS replace plugs in column fittings to prevent the column

from drying out when not in use.

b. column storage

• The column may be stored 1-2 days in Buffer A without flow. The

presence of phenol in the buffer will prevent bacterial growth.

• For longer storage periods, 0.2 N NaOH is strongly recommended.

c. column regeneration

For protein hydrolyzate samples, regenerate the column at least

once a week as follows:

Eluent:

0.2 N NaOH

Flow:

0.5 ml/min

Temperature: 62°C

Flush Time:

30 min

Crude samples may require more frequent regeneration.

d. troubleshooting

This section discusses some possible problems and their solutions

(refer to Table 1.)

e. regeneration of Protein and lipid contaminated column

• Large proteins and some lipids can be removed following alkaline

hydrolysis.

• Reverse direction of buffer flow through column. Elevate column

heater temperature to 90°-95°C and pump 0.2 N NaOH solution

through column for at least 2 hours. Particularly difficult contamination

may require overnight treatment.

• Restore normal flow direction and temperature; reequilibrate

column with Buffer A and test column with amino acid standard

solution. If problem still exists, repeat the above treatment.

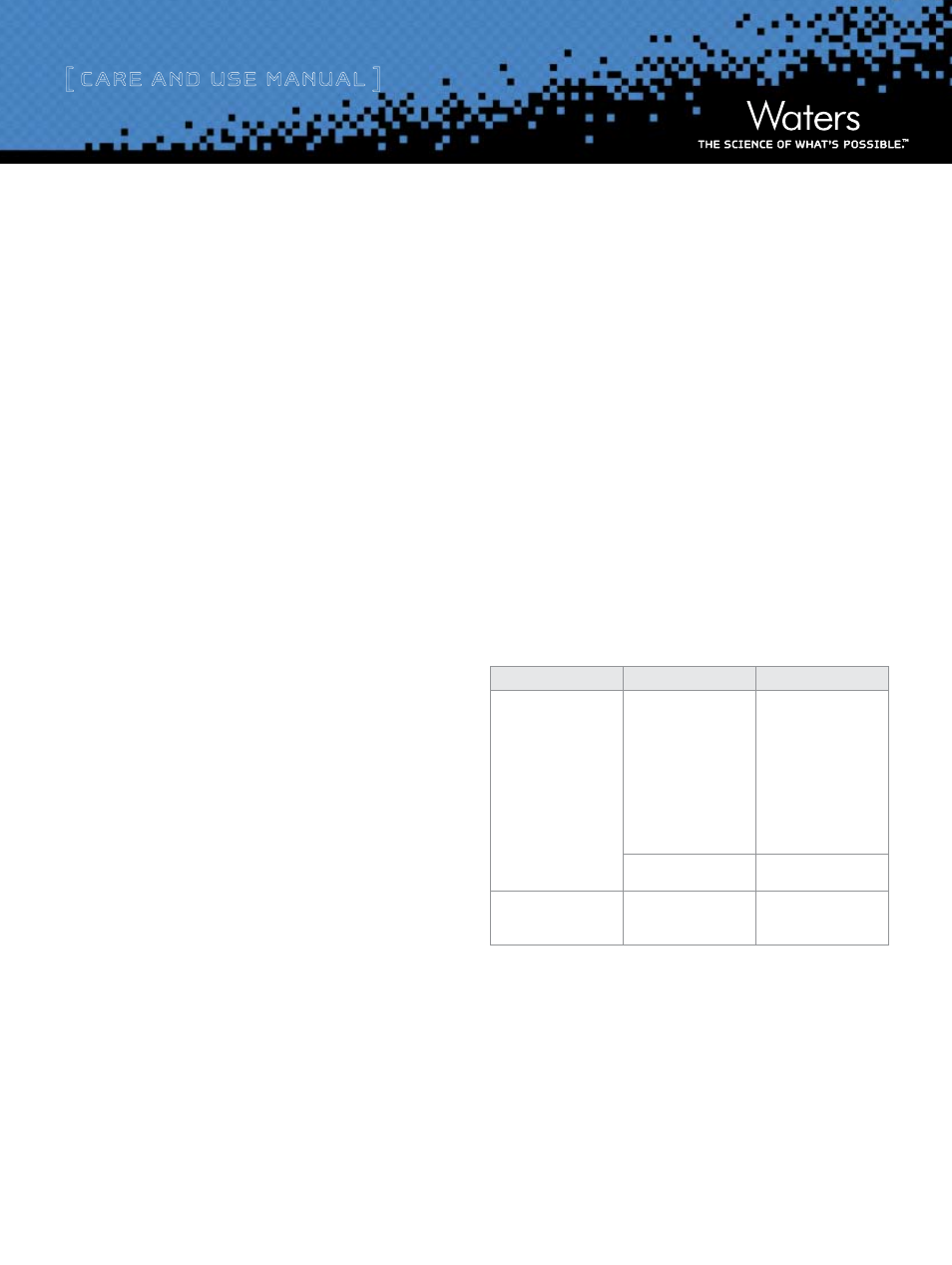

Table 1: Typical Column Problems and Solutions

Problem

Cause

Solution

Excess pressure buildup

Column frits plugged with

particulates or mold is

growing in column or in

buffers

Reverse flow on column.

If this does not work,

follow procedure for protein

removal. If pressure is still

high, carefully remove

column inlet fitting being

sure not to disturb resin.

Clean in ultrasonic bath.

Always filter solvents and

samples.

Sample and/or buffer

precipitates on column

Follow procedure above.

Loss of resolution, broad

peaks, low plate counts

Contaminated column

Follow procedures

for metal and protein

removal.