Care and use manual – Waters Sugar-Pak I Column User Manual

Page 2

[ Care and Use ManUal ]

Sugar-Pak I Columns

2

II. PRePARAtIon FoR oPeRAtIon

a. Column Installation

Remove the end plugs from the steel column with a 5/16-inch open-

end wrench and save them for storage when the column is removed

from the system. The column outlet is indicated by an arrow on the

label (showing the direction solvent should flow). Tighten the fittings

to turn past finger tight. DO NOT OVERTIGHTEN – this will damage the

fitting seat. A properly prepared and assembled compression fitting in

good condition is all that is required.

If tube cutting is required to connect a new column or to improve the

end connections on your existing fittings, follow these steps:

1. Use a file with a cutting edge (such as the file included in the

Startup Tool Kit, P/N WAT096146) to scribe the circumference of

the tube at the desired break.

2. Grasp the tube on both sides of the scribe mark with cloth-

covered or smooth-faced pliers (to prevent marring the tube

surface) and gently work the tube back-and-forth until it

separates.

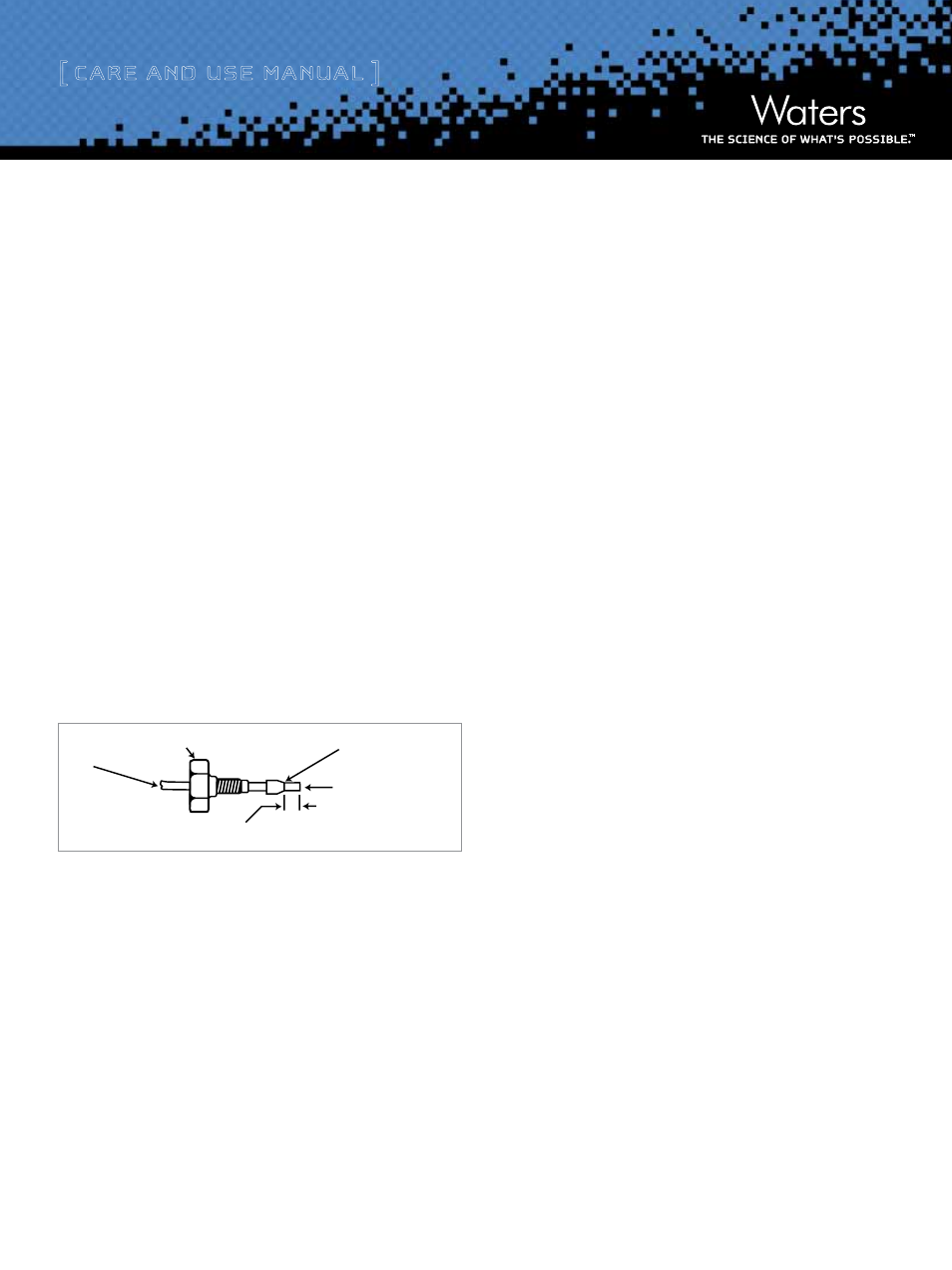

Figure 1. Ferrule and compression assembly.

3. Inspect the tube at the break for burrs. File the outer edges at an

angle to the tube opening. Do not file flat across the open tube

as this might cause plugging or uneven flow delivery. Assemble

as shown.

4. Slide the compression fitting over the tube, followed by the

ferrule (large end of the taper first).

5. Seat the ferrule by tightly mating the assembly to the fitting seat

in which it will be used. An improperly positioned ferrule can

form unwanted dead volume which could result in unintentional

sample mixing.

Note: Attach a union in place of the column and flush the lines

free of microparticulates before attaching the column.

b. Mobile-Phase Requirements

This column is packed with a calcium-loaded resin. Hydrogen or

other cations can replace the calcium and cause inversion on the

column of sugars such as sucrose, which are prone to inversion.

It is recommended that a small amount of calcium be used in the

mobile phase to maintain the equilibrium and prevent inversion.

The recommended mobile phase is deionized, bacteria-free water

containing approximately 0.0001 M calcium EDTA* (50 mg/L).

* Calcium EDTA has several common names:

- Calcium di-sodium (ethylene dinitrilo) tetra-acetic acid

- Calcium di-sodium ethylene diamine tetraacetate

- Calcium di-sodium edentate

Water should be deionized to greater than 2 megohms resistivity.

It is essential that the water used is free of polyvalent cations,

particularly transition and heavy metals (e.g., iron).

Remove bacteria and other particulates from the water just

before use by vacuum filtration. The Solvent Clarification Kit is

recommended for solvent filtration (110 V, P/N WAT085113;

240 V, P/N WAT085122) using PES filter membranes (P/N

WAT200538).

Although the mobile phase will be partially degassed by vacuum

filtration, it is highly desirable that it be thoroughly degassed by

the following procedure:

1. Place the mobile phase in an Erlenmeyer flask on a

stirrer/hot plate.

2. Cover the mouth of the flask with aluminum foil to minimize

evaporation.

3. Bring the mobile phase to its boiling point for a few

minutes just before use, but maintain the temperature

between 70-90 °C during use. This practice ensures that

gases (especially C0

2

) do not redissolve in the mobile

phase. It also prevents the growth of microorganisms.

4. Keep the mobile-phase reservoir clean and covered and supply

freshly prepared mobile phase every 24 hours.

If the system is to be used continually for more than one

day, place the mobile phase in an Erlenmeyer flask on a

stirrer/hot plate. Cover the mouth of the flask with aluminum

COMPRESSION SCREW OR NUT

TUBE

FERRULE

END MUST BE STRAIGHT

AND SMOOTH TO ACHIEVE

MAXIMUM COLUMN EFFICIENCY

CRTITICAL DISTANCE TO BE DETERMINED BY

EACH APPLICATION (UNION, COLUMN FITTING, ETC.)