Care and use manual – Waters Protein-Pak HR Ion-Exchange Glass Columns User Manual

Page 9

[ Care and Use ManUal ]

Protein-Pak HR Ion-Exchanged Glass Columns

9

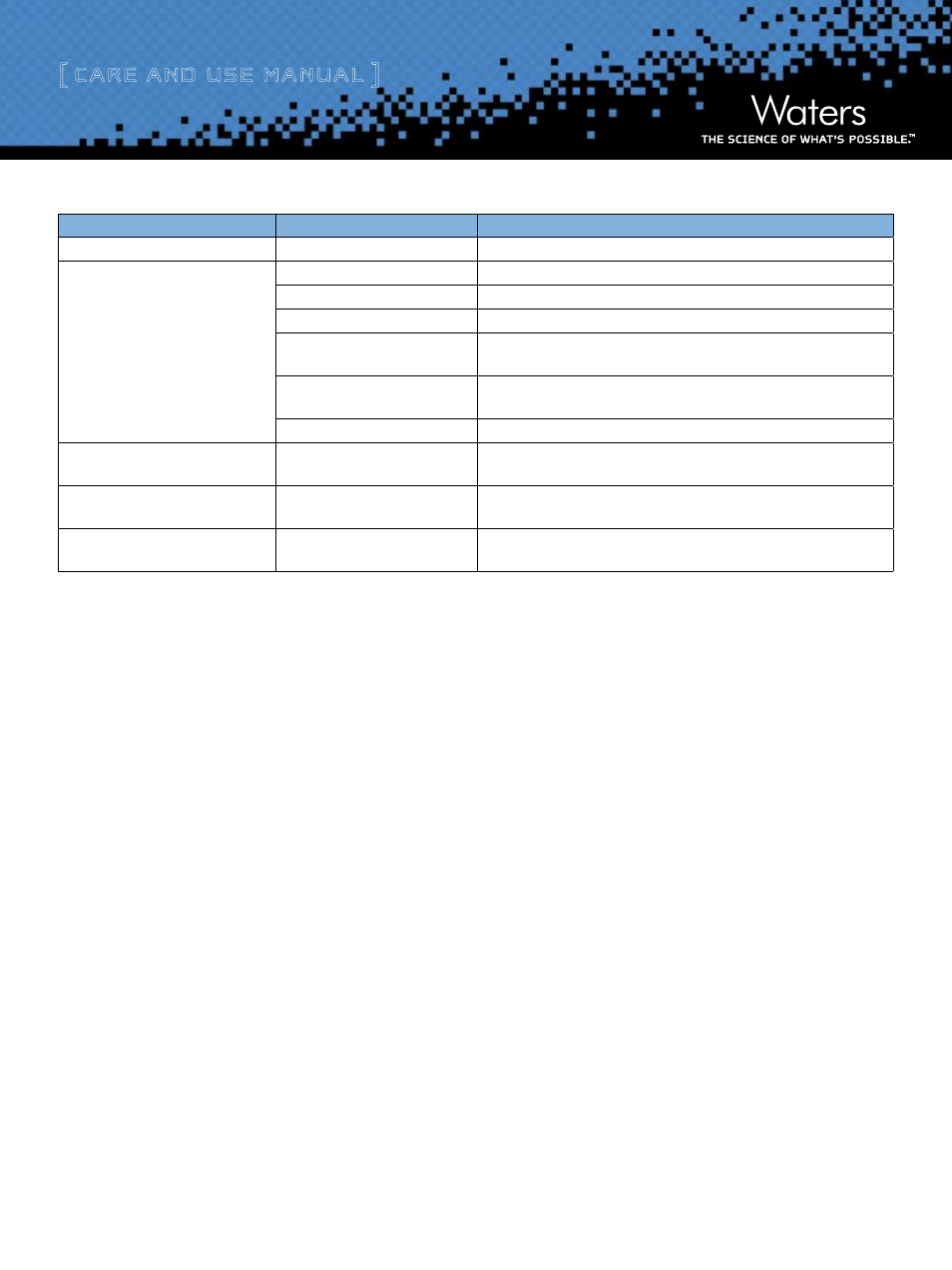

Problem

Cause

Solution

Noisy baseline

Gas in the mobile phase

Degas buffers or solvents prior to use. Sparge buffers during use.

Poor resolution

Sample overload

Reduce sample amount.

Flow rate too high

Reduce flow rate.

Gradient volume too small

Increase gradient volume.

Packed bed void

Tighten fine adjustment to eliminate void. Top off the column with appropriate

packing material.

Packing material fouled

Refer to packing material instructions for suitable cleaning agents (see Section

V, b).

Plugged column filters

Replace filter.

High backpressure

Fouled packing material

Plugged column filters

Flush with suitable cleaning agent. Replace filter.

Leakage at the compression screw

end fittings

Worn ferrules

Replace ferrules.

Leakage into the plastic shield or out of

the inlet connection assembly

Worn 0-rings

Replace 0-rings.

b) Column Cleaning and Regeneration

When column performance deteriorates because of sample

contamination, perform the following cleaning procedures to

regenerate the ion-exchange packing materials. Perform all washes

at half the recommended flow rates (refer to Section IV, Operating

Parameter Limits).

Part A

1. Wash the column with 4 column volumes of water to remove buffer

salts.

2. Flush the column with 4 column volumes of 0.1 M NaOH followed by 4

column volumes of water.

3. Pass 4 column volumes of 30% acetic acid (V/V) through the ion

exchanges, followed by 4 column volumes of water.

4. Flush 4 column volumes of 1 M NaCl to ensure that DEAE HR or Q HR

is in the chloride form and that SP HR or CM HR is in the sodium form.

5. Equilibrate with an appropriate buffer and repeat the functional test

outlined in Section V, a), Troubleshooting.

Part B

If column performance does not improve after Part A:

1. Incubate the column overnight with a proteolytic-enzyme solution

(1 mg/mL pepsin, trypsin, and papain) or nuclease solution (DNase)

under conditions for optimal enzyme activity.

2. After incubation, repeat Part A.

Part C

If you suspect lipid contamination:

1. Follow Part A procedures up to and including step 3.

2. Wash with 4 column volumes of 50% aqueous ethanol (absolute),

followed by 4 column volumes of water.

3. Equilibrate with an appropriate buffer (see Table 4), and repeat the

functional test outlined in Section V, a), Troubleshooting.

c. Storage Considerations

•

Store the columns in distilled water. It microbial contamination is

a concern, refrigerate at 4-6 °C or 39-43 °F. DO NOT FREEZE. For

long-term storage a 0.02% sodium azide solution or a 50% aqueous

ethanol solution may be used.

•

Return the column to its box with the end caps firmly in place for stor-

age. Allowing columns to dry out can result in poor chromatographic

performance.

Table 6: Typical Column Problems and Solutions