Care and use manual, V. t roubleshooting, Xbridge protein beh c – Waters XBridge Protein BEH, C4, 300A, 3.5 µm Columns User Manual

Page 7: Waters preparative obd columns calculator

7

[ CARE AND USE MANUAL ]

XBridge Protein BEH C

4

, 300Å, 3.5, 5, 10 �m

§

Very strongly dependent on loading conditions

–

Limited by loading volume

–

Limited by diluent solvent strength

Waters Preparative OBD Columns Calculator

§

Convenient scale-up tool provides:

- Mass load scaling

- Gradient scaling with appropriate flow rate scale-up

and predicting volume consumption

- Calculations for split flow ratios for those using mass

spectrometer driven chromatography

- Focused gradient UPLC to preparative method transfer

AU

0.00

0.10

0.20

0.30

0.40

AU

0.00

0.10

0.20

0.30

0.40

AU

0.00

0.10

0.20

0.30

0.40

AU

0.00

0.10

0.20

0.30

0.40

Minutes

2.00

4.00

6.00

8.00

10.00

12.00

14.00

16.00

18.00

20.00

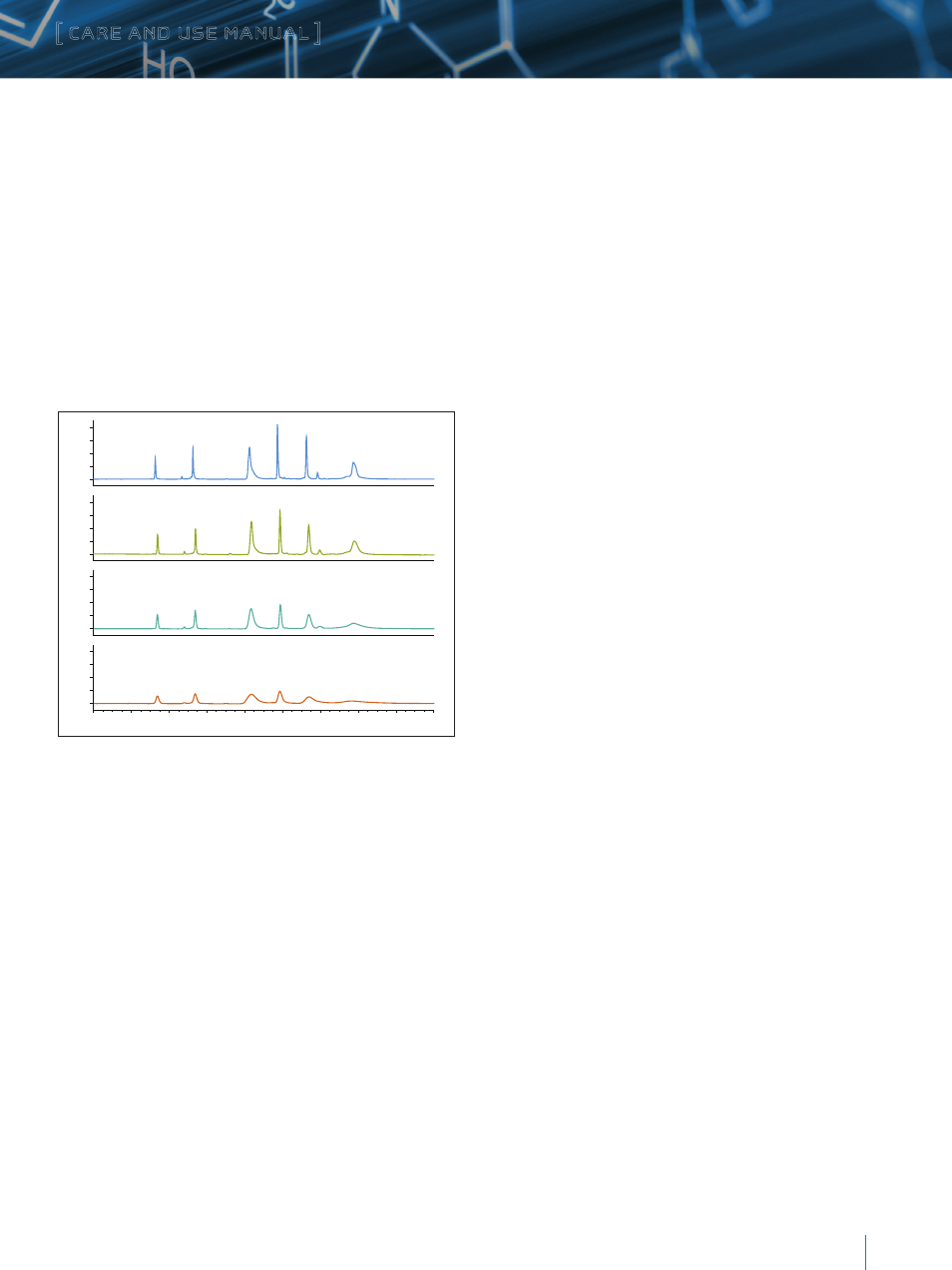

ACQUITY UPLC Protein BEH C

4

,

300Å, 1.7 µm

XBridge Protein BEH C

4

, 300Å, 3.5 µm

XBridge Protein BEH C

4

, 300Å, 5 µm

XBridge Protein BEH C

4

, 300Å, 10 µm

Figure 3: Separation of MassPREP Protein Standard Mixture on ACQUITY UPLC

Protein BEH C

4

, 300Å, 1.7 μm (Top), XBridge Protein BEH C

4

, 300Å, 3.5μm, XBridge

Protein BEH C

4

, 300Å, 5 μm, XBridge Protein BEH C

4

, 300Å, 10 μm using scaling

methods obtaining using Waters Preparative Chromatography OBD Calculator.

V. T ROUBLESHOOTING

The first step in systematic troubleshooting is comparison of the

column, in its current state, to the column when it was functioning

properly. The method suggested in Section I for measuring plate

count is an essential first step. This technique detects physical

changes to the packed bed and chemical changes in the bonded

phase surface. The two functional tests with the Peptide Standard

and the Protein Mixture may reveal more subtle changes in surface

chemistry that affect the application.

There are several common symptoms of change in the column.

1. An increase in pressure is often associated with lost

performance in the application. The first step in diagnosis

is to ensure that the elevated pressure resides in the column

rather than somewhere else in the system. This is determined

by measuring pressure with and without the column attached

to the instrument. If the system is occluded, the blockage

should be identified and removed. If the pressure increase

resides in the column, it is helpful to know whether the

problem was associated with a single injection or whether

it occurred over a series of injections. If the pressure

gradually built up, it is likely that the column can be cleaned

as described below (Section V). For future stability, it may

be useful to incorporate a stronger regeneration step in the

method. If a single sample caused the pressure increase,

it likely reflects particulates or insoluble components,

such as, lipids. Cleaning is still an option, but using the

more aggressive options. The sudden pressure increase

suggests that the user should consider some sample

preparation, such as filtration or high speed centrifugation.

2. Loss of retention can reflect a change in the column surface

chemistry. Before proceeding with diagnostic or corrective

measures, check that the mobile phases have been correctly

prepared and the correct method has been selected. Then

repeat the efficiency test and the functional peptide or

protein test. If both the small and large molecule test

show loss of retention, it is likely that a significant fraction

of the bonded phase has been lost, and the column will

require replacement. If the changes are small and reflected

only for some proteins, one of the cleaning procedures may

be effective.

3.

Change in peak shape, resolution, or relative retention of

peaks. Follow the same steps as for loss of retention (Symptom 2).

4. Carryover and memory effects are defined as the appearance

of the constituents of one sample in the next gradient analysis.

First determine whether the column or the system is the source

of carryover. Define a gradient method that includes an “inter-

nal gradient”. That is, the analytical gradient is repeated within

a single method. If the protein peaks appear in both gradients,

at the same time after start, the protein came from the column

in what is often described as a “memory effect”. If the protein

peaks only appear when an injection is made, they likely origi-

nate from adsorption to some system component. In that case,

follow the instrument manufacturer’s recommendations. Memory

effects as a source of carryover may be reduced or eliminated

in several ways. First, raising the temperature of the separation