Care and use manual – Waters XBridge Protein BEH, C4, 300A, 3.5 µm Columns User Manual

Page 6

6

[ CARE AND USE MANUAL ]

XBridge Protein BEH C

4

, 300Å, 3.5, 5, 10 �m

c. Solvents

To maintain maximum column performance, use high quality

chromatography grade solvents. Filter all aqueous buffers prior to

use. Pall Gelman Laboratory Acrodisc

®

filters are recommended.

Solvents containing suspended particulate materials can damage

the fluidic components of the HPLC system and will generally clog

the inlet distribution frit of the column. This will result in higher

operating pressure and poor performance.

d. Pressure

XBridge Protein BEH C

4

, 300Å, 3.5, 5, and 10 µm Columns

can tolerate pressures of up to 6,000 psi (400 bar or 40 Mpa)

although pressures greater than 4,000-5,000 psi should be

avoided in order to maximize column and system lifetimes.

e. Temperature

Temperatures between 20–90 ˚C are recommended for operating

XBridge Protein BEH C

4

, 300Å Columns in order to enhance

selectivity, lower solvent viscosity and increase mass transfer

rates. However, any temperature above ambient will have a

negative effect on lifetime which will vary depending on the pH

and buffer conditions used.

IV. SCALING SEPARATIONS

Scale-Up Factors

Scale-up factor =

Consider scaling up from a 4.6 x 150 mm column to a

19 x 150 mm column:

Scale-up factor = = 17.1

Applying the scale-up factor, we can predict that approximately

17-135 mg of sample could be applied to the larger column (packed

with the same material as the analytical column). This range is

based on an analytical (4.6 mm I.D.) mass load of 1-8 mg.

Flow Rate

Flow rate (prep) = Flow rate (analytical) x

The calculated flow rate may be used for the larger column to ensure

the same linear velocity of mobile phases as used in the analytical

run. However, reasonable flow rates are based on column diameters.

Systems will be limited by increasing backpressure with increasing

column length and decreasing particle size.

Gradient Duration (GD)

GD (prep) =

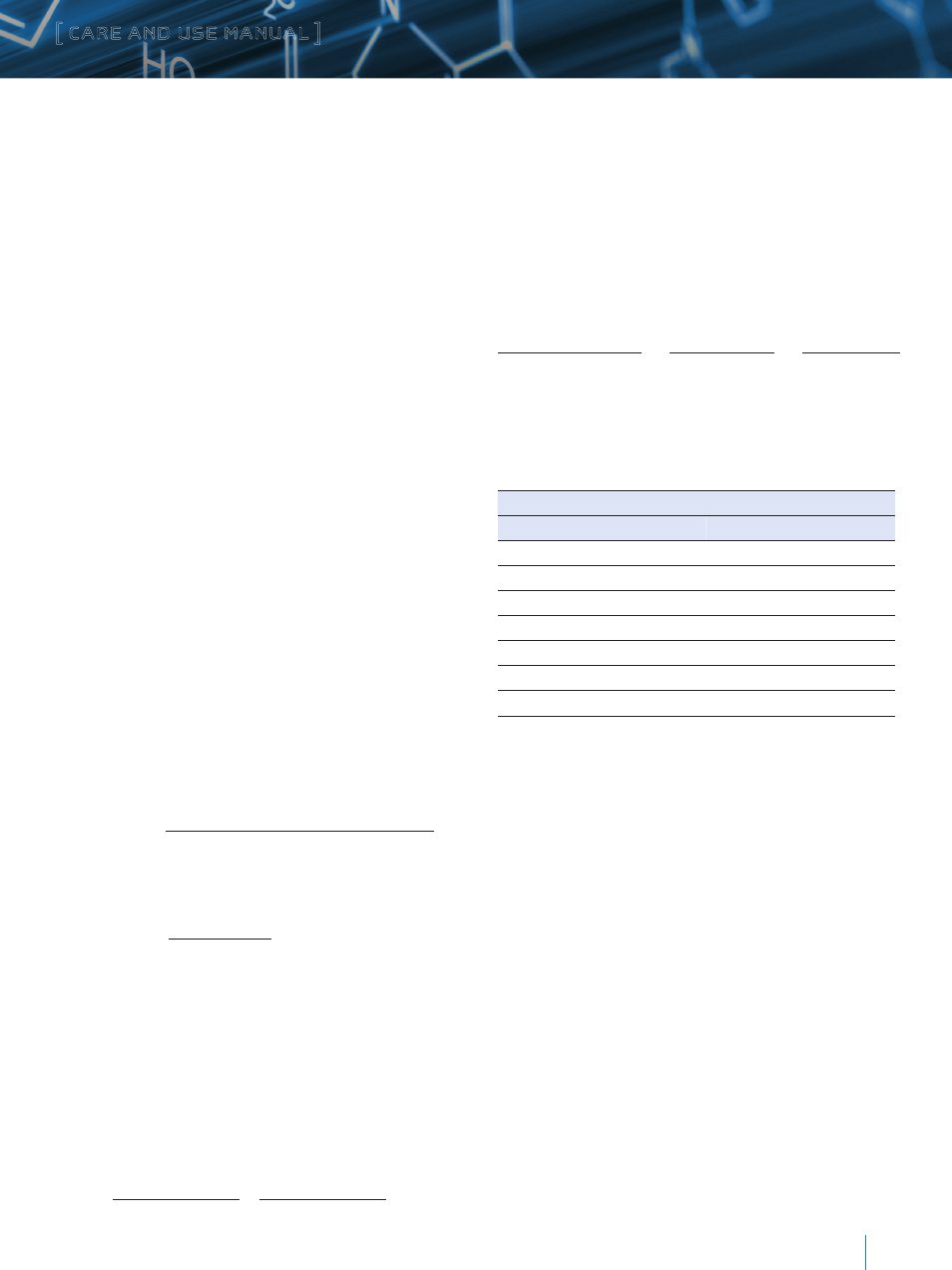

Mass Loading

Approximate Mass Loading Capacity (mg) for Preparative OBD

Columns (Gradient Mode)

Diameter (mm)

Length (mm)

4.6

10

19

30

50

3

15

45

110

75

–

–

–

165

100

5

25

90

225

150

8

40

135

335

250

13

60

225

560

Reasonable Flow Rate (mL/min)

1.4

6.6

24

60

Reasonable Injection Volume (µL)

20

100

350

880

The calculated prep gradient duration is entered into the pump’s

gradient separation over the same number of column volumes as

was used in the analytical run.

Reasonable flow rates are based on column diameter. Systems will be

limited by increasing backpressure with increasing column length and

decreasing particle size.

Reasonable injection volumes are based on column diameter at a

length of 50 mm with relatively strong solvents. Increased length

is compatible with larger injection, but not proportionately so.

Weaker solvents significantly increase injection volume.

Mass loading capacities for peptide purifications depend strongly

on the sequence and may be estimated at 5–20% of listed values.

Many factors affect the mass capacity of preparative columns. The

listed capacities represent an ‘average’ estimate.

Capacity is:

§

Higher for strongly retained material

§

Higher for simple mixtures

§

Lower where higher resolution is required

(19)

2

x 150

(4.6)

2

x 150

(Diameter prep)

2

x Length prep

(Diameter analytical)

2

x Length analytical

GD (anal) x Length (prep)

x

Diameter (prep)

2

x

Flow Rate (analytical)

Length (analytical)

Diameter (analytical)

2

Flow Rate (prep)

(Diameter prep)

2

Particle Size (analytical)

(Diameter analytical)

2

Particle Size (prep)

x