Care and use manual – Waters ACQUITY UPC2 BEH, HSS, and CSH Columns User Manual

Page 2

2

[ CARE AND USE MANUAL ]

ACQUITY UPC

2

Torus Columns Care & Use

II. GET TING START ED

Each ACQUITY UPC

2

Column comes with a Certificate of Analysis

and a Performance Test Chromatogram. The Certificate of Analysis

is specific to each batch of packing material and includes the gel

batch number, physical characterization, analysis of unbonded

particle, analysis of bonded particles, and a SFC chromatographic

batch test. The Performance Test Chromatogram is specific to

each individual column and contains the following information:

gel batch number, column serial number, USP plate count, USP

tailing factor, capacity factor, and chromatographic conditions

under normal-phase LC conditions. These data should be stored for

future reference.

a. Safety Considerations

An SFC column, while in use, is under pressure with CO

2

and

possible modifiers as a supercritical fluid. A major safety concern

is frostbite caused by adiabatic cooling when CO

2

decompresses

from a fluid to a gas at atmospheric pressure. Pay attention to any

frosting on the column or system connections. This indicates a

leak, usually with temperatures far below 0 °C.

Any small leak could produce a situation where the LEL (lower

exposure limit) is reached. Laboratories should be equipped with

CO

2

and/or O

2

sensors when carbon dioxide (CO

2

) is in use.

b. Column Connectors and Installation

ACQUITY UPC

2

Systems utilize tubing and connectors which have

been designed to meet stringent tolerance levels and to minimize

extra column volumes. For information on system tubing and

connectors, please refer to the ACQUITY UPC

2

System Operator’s

Guide (Part Number 720004226EN).

Note: Scale the flow rate up or down accordingly based upon

the column i.d., length, particle size, and backpressure of the

ACQUITY UPC

2

Column being installed.

1. Make sure your co-solvent pump is primed and has an adequate

solvent/modifier supply before performing injections. It is

recommended to use CO

2

with purity level of 99.97%

(food grade) and use high-quality chromatography grade

solvents (typically methanol) as organic modifier.

2. Connect both the inlet and outlet of the column to the

SFC system.

3. If the column is still filled with a solvent, use a low flow

rate and back pressure setting (100 bar) to start pumping

CO

2

and modifier through the column.

4. If you see frosting on the column at the inlet or outlet, tighten

the finger-tight fitting or compression screw on that side. If you

continue to see frosting, turn off the CO

2

and vent the system.

Allow the column to depressurize fully before disconnecting

the inlet or outlet to troubleshoot the leaking issue.

c. eCord Installation

The eCord

®

button should be attached to the side of the column

heater module. The eCord button is magnetized and does not

require specific orientation.

d. Column Equilibration

ACQUITY UPC

2

Columns are shipped dry. Equilibrate the column

with a minimum of 10-column volumes of the mobile phase prior

to use. (Refer to Table 2 for a listing of empty column volumes.)

e. Initial Column Efficiency Determination

1. Perform an efficiency test on the column before using it.

Waters recommends using a suitable solute mixture to analyze

the column upon receipt. We recommend that weaker solvents

are selected as injection solvents. Peak distortion can occur

due to strong solvent effects, resulting in lower efficiency

values. (Methanol can be considered a strong solvent under

SFC conditions.)

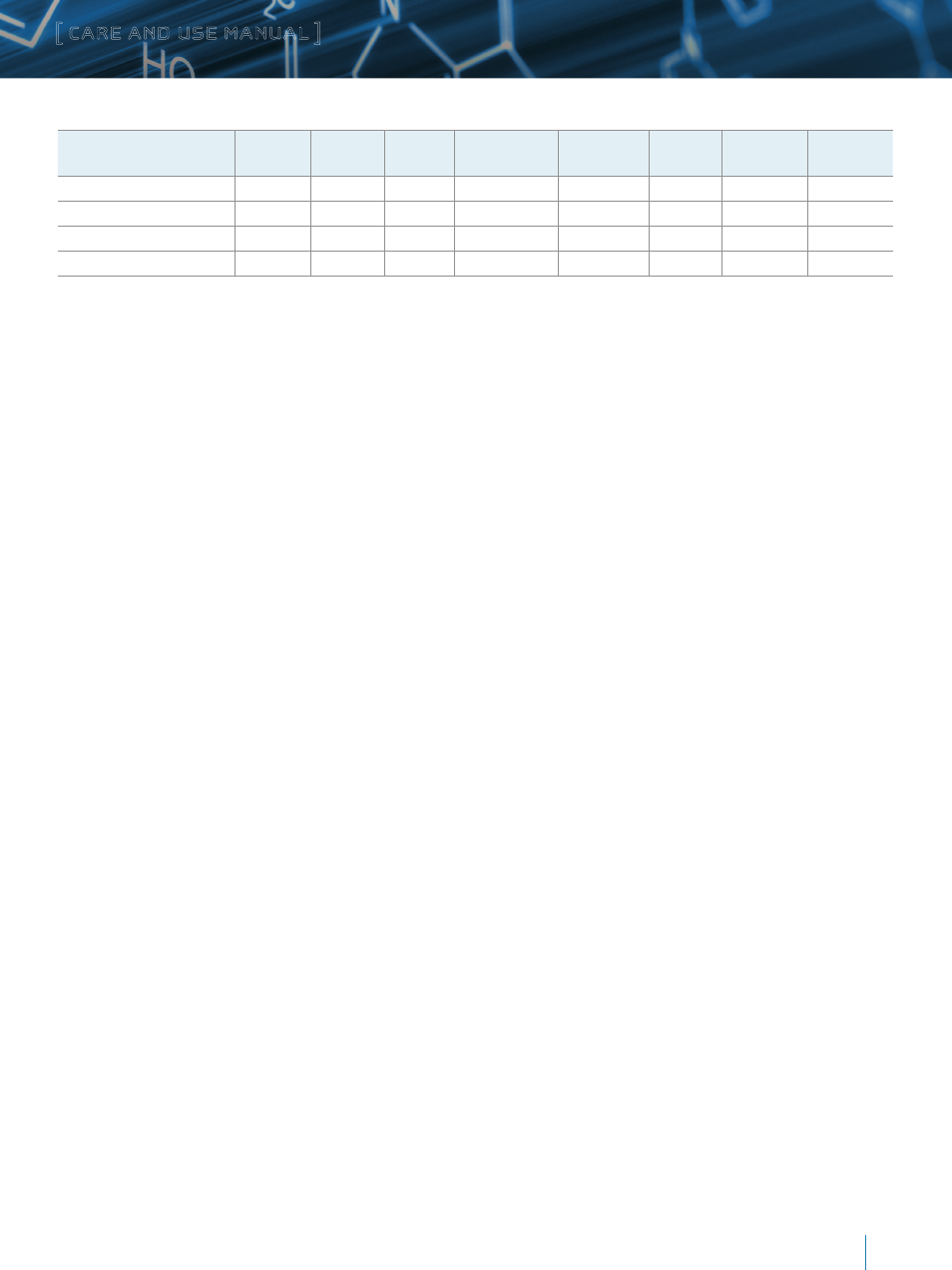

Table 1. Physical Characteristics.

Chemistry

Particle

Shape

Particle

Size (µm)

Pore

Size (Å)

Surface Area

(m2/g)

Pore Volume

(cc/g)

Carbon

Load (%)

Endcapped

Particle

Technology

BEH 2-Ethylpyridine (2-EP) Spherical

1.7, 3.5

130

185

0.7

9

No

BEH

BEH (Unbonded)

Spherical

1.7, 3.5

130

185

0.7

N/A

N/A

BEH

CSH Fluoro-Phenyl

Spherical

1.7, 3.5

130

185

0.7

10

No

CSH

HSS C

18

SB

Spherical

1.8, 3.5

100

230

0.7

8

No

HSS