Care and use manual – Waters XSelect CSH XP 2.5 µm Columns User Manual

Page 7

XSelect CSH XP 2.5 µm Columns

7

[ CARE AND USE MANUAL ]

c. Solvents

To maintain maximum column performance, use high quality HPLC

or MS grade solvents. Filter all aqueous buffers prior to use through

a 0.2 µm filter. Solvents containing suspended particulate materials

will generally clog the outside surface of the inlet of the column.

This may result in higher backpressure or distorted peak shape.

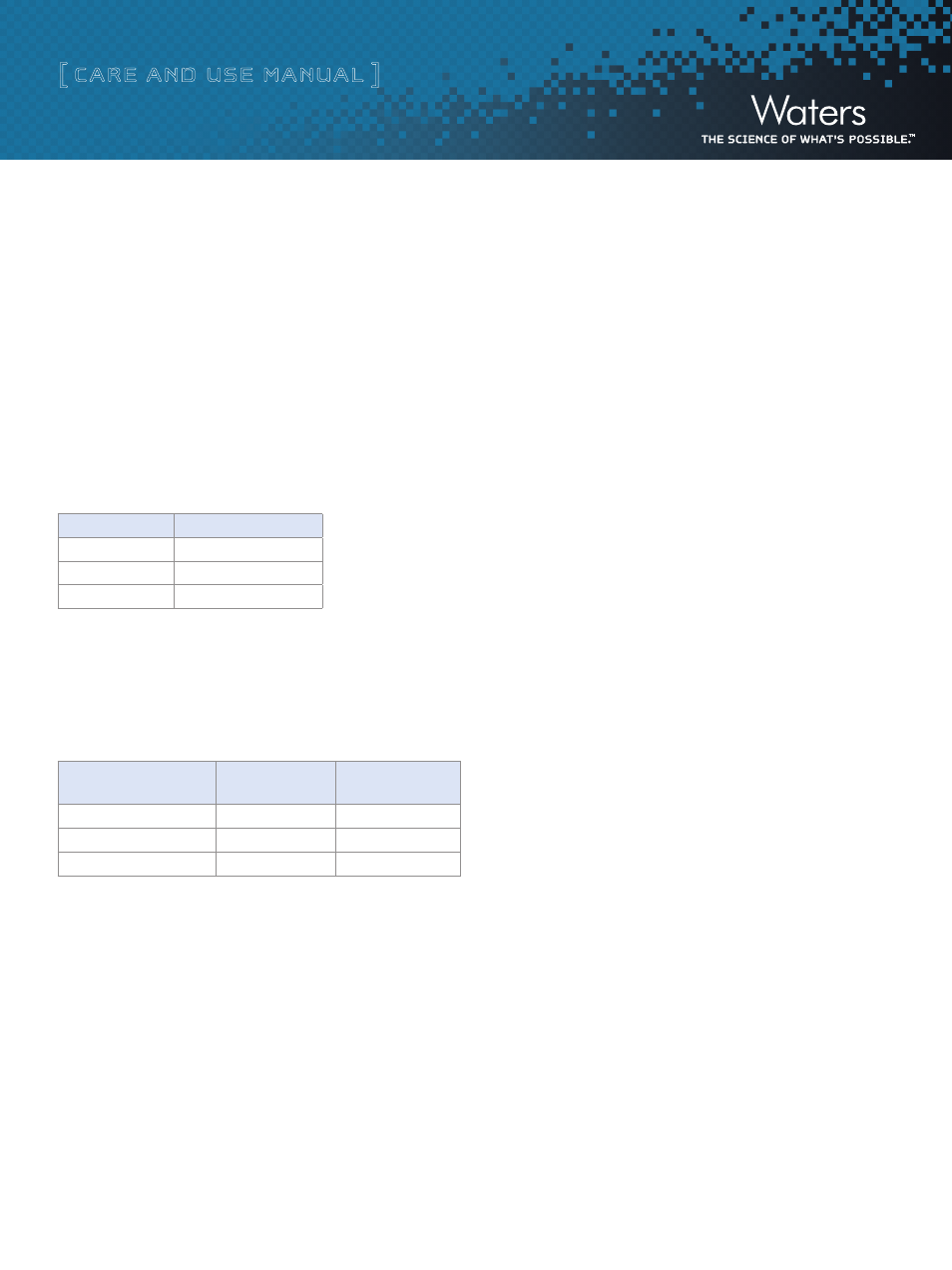

d. Pressure

XSelect CSH XP 2.5 µm Columns are compatible with HPLC, UHPLC and

UPLC pressures. Table 6 depicts the maximum operation pressure.

Table 6: Maximum Operation Pressure

Column ID

Pressure Range

2.1 mm

18,000 psi [1034 bar]

3.0 mm

18,000 psi [1034 bar]

4.6 mm

9000 psi [620 bar]

e. Temperature

XSelect CSH XP 2.5 µm Columns can be used up at intermediate

temperatures to enhance selectivity, reduce solvent viscosity and

increase mass transfer rates.

Chemistry

Temperature Limit

Low pH

Temperature Limit

High pH

XSelect CSH C

18

80 °C

45 °C

XSelect CSH Phenyl-Hexyl

80 °C

45 °C

XSelect CSH Fluoro-Phenyl

60 °C

45 °C

Note: Working in combinations of extreme pH, temperature and pressure may

result in reduced column lifetime.

IV. COLUMN CLEANING, REGENERATION AND STORAGE

a. Cleaning and Regeneration

Changes in peak shape, peak splitting, shouldering peaks, shifts

in retention, change in resolution or increasing backpressure may

indicate contamination of the column. Flush with a neat organic

solvent to remove the non-polar contaminant(s), taking care not to

precipitate any buffered mobile-phase components. If this flushing

procedure does not solve the problem, purge the column with the

following cleaning and regeneration procedures.

Use a cleaning routine that matches the properties of the samples,

stationary-phase type (reversed-phase, normal-phase or HILIC) and

will solubilize the suspected contaminate. Flush with 20 column

volumes of solvent at an intermediate temperature of 45 °C. Return

to the initial mobile-phase conditions by reversing the sequence.

If using a reversed-phase column, purge the column with a sequence

of progressively more non-polar solvents (i.e., water-to-methanol-to-

tetrahydrofuran-to-methylene chloride).

If column performance has not improved after regeneration/

cleaning procedures, contact your local Waters representative for

additional support.

b. Storage after Reversed-Phase Use

For periods longer than four days, store the XP 2.5 µm Column in

100% acetonitrile. For separations utilizing elevated temperature,

store immediately after use in 100% acetonitrile. Do not store

columns in buffered eluents. If the mobile phase contained a buffer

salt, flush the column with 10 column volumes of HPLC grade water

(see Table 3 for column volume information) followed by 10 column

volumes of acetonitrile. Failure to perform this intermediate step

could result in precipitation of the buffer salt in the column when

100% acetonitrile is introduced. Completely seal the column to avoid

solvent evaporation and drying out of the chromatographic bed.

Note: If a column has been run with a formate-containing mobile phase

(e.g., ammonium formate, formic acid, etc.) and is purged with 100%

acetonitrile, slightly longer equilibration times may be necessary when the

column is re-installed and re-wetted with that same formate-containing

mobile phase.

V. eCORD INTELLIGENT CHIP TECHNOLOGY

a. Introduction

The eCord Intelligent Chip Technology represents a significant

advancement in column usage tracking management which can be

realized if the column is installed on an ACQUITY UPLC System.

The eCord Intelligent Chip provides a paperless tracking history of the

column’s performance and usage throughout its lifetime. The eCord

is permanently attached to the column body via a tether that cannot

be removed. This ensures that the history of the column is always

accessible to the user of that column.