Care and use manual – Waters Oligonucleotide Separation Technology XBridge OST C18 Columns User Manual

Page 2

[ CARE AND USE MANUAL ]

2

I. GET TING STARTED

Each XBridge OST C

18

column is shipped with a Certificate of

Analysis and a Performance Test Chromatogram document. The

Certificate of Analysis is specific to the batch of packing material

contained in the XBridge OST C

18

column and includes the gel batch

number, analysis of unbonded particles, analysis of bonded particles,

and chromatographic results and conditions. The Performance Test

Chromatogram is specific to each individual column and contains

such information as gel batch number, column serial number, USP

plate count, USP tailing factor, capacity factor, and chromatographic

conditions. These data should be stored for future reference.

a. Connecting the Column

1. Purge the pumping system of any buffer-containing mobile phases

and connect the inlet end of the column to the injector outlet.

2. The XBridge OST C

18

column should be connected to HPLC with

1/16 inch tubing (stainless steel or PEEK

™

). An arrow on the column

identification label indicates the correct direction for solvent

flow. Make sure that XBridge OST C

18

column connection is made

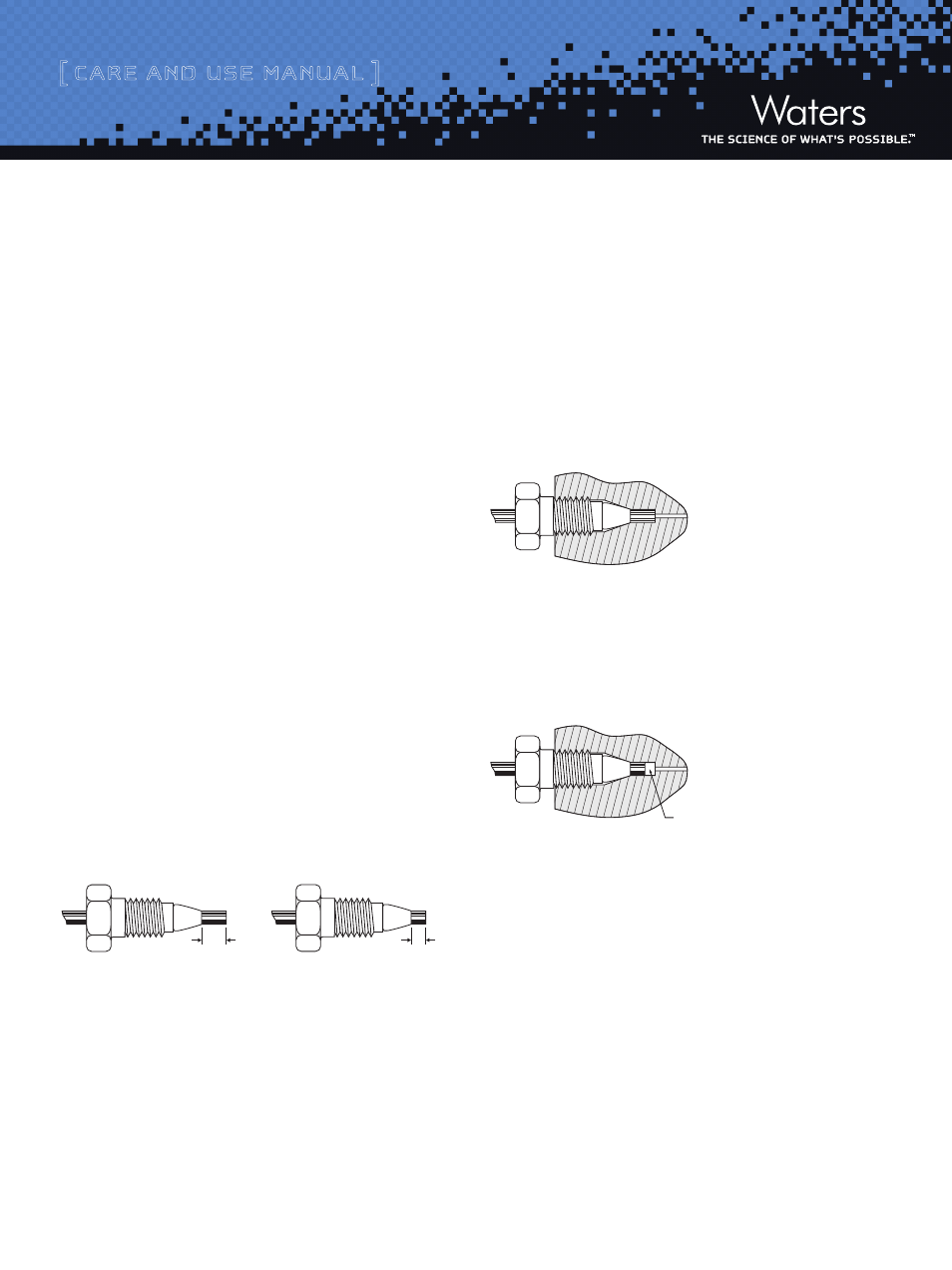

with the correct ferrule seating adjustment. Figure 1 shows

the differences between Waters and Parker style of ferules and

end fittings. Note the differences in end fitting style and length of

tubing protruding from the ferrule end.

Figure 1: Waters and Parker Ferrule Types

Due to the absence of an industry standard, various column

manufacturers have employed different types of chromatographic

column connectors. The chromatographic separation can be

negatively affected if the style of the column endfittings does not

match the existing tubing ferrule setting. This section explains

the differences between Waters style and Parker style ferrules

and endfittings (Figure 1). Each endfitting style varies in the

required length of the tubing protruding from the ferrule. The

XBridge OST C

18

column is equipped with Waters style endfittings

that require a 0.130 inch ferrule depth. If a non-Waters style column

is presently being used, cut the end of the tubing with the ferrule,

place a new ferrule on the tubing and make a new connection. Before

tightening the screw, make sure that the tubing bottoms out in the

endfitting of the XBridge OST C

18

column.

In a proper tubing/column connection (Figure 2), the tubing touches

the bottom of the column endfitting, with no void between them.

Figure 2: Proper Tubing/Column Connection

The presence of a void in the

flow stream reduces column

performance. This can occur if

a Parker ferrule is connected

to a Waters style endfitting

(Figure 3).

Note: A void appears if tubing with a Parker ferrule is connected to a

Waters style column.

Figure 3: Parker Ferrule in a Waters Style Endfitting

There is only one way to fix

this problem. Cut the end of

the tubing with the ferrule,

place a new ferrule on the

tubing and make a new

connection. Before tightening

the screw, make sure that the tubing bottoms out in the endfitting of

the column.

Conversely, if tubing with a Waters ferrule is connected to a column

with Parker style endfitting, the end of the tubing will bottom out

before the ferrule reaches its proper sealing position. This will leave

a gap and create a leak (Figure 4).

Note: The connection leaks if a Waters ferrule is connected to a column

with a Parker style endfitting.

Waters Ferrule Setting

0.130 inches

Parker Ferrule Setting

0.090 inches

.090”

.130”

Void