Waters ACQUITY APC Columns User Manual

Page 5

5

ACQUITY APC Columns

Table 4. Viscosity of Common Solvents at

Different Temperatures **

Solvent

Viscosity (cP)

20 °C

40 °C

Acetone

0.32

0.26

Chloroform

0.57

0.45

Dimethyl formamide (DMF)

0.92

0.68

Dimethyl sulfoxide (DMSO)

2.00

1.50

Ethyl Acetate

0.44

0.36

Hexane

0.33

0.26

Methanol

0.60

0.44

Methylene chloride

0.44

N/A

N-Methylpyrrolidone (NMP)

1.70

1.30

Tetrahydrofuran (THF)

0.55

0.39

Toluene

0.59

0.46

Water

1.00

0.67

d. Minimizing Band Spread

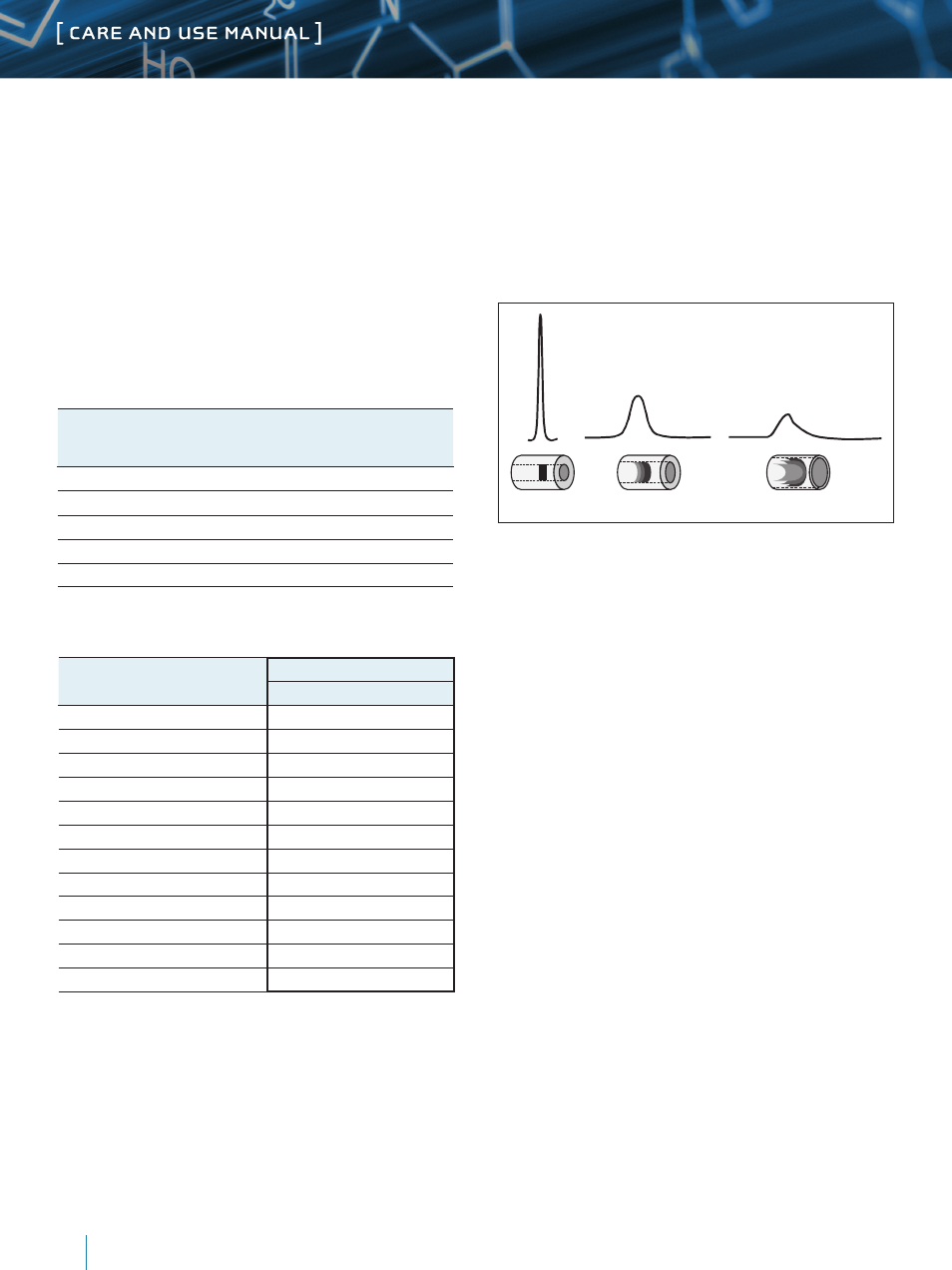

The ACQUITY APC System was designed to minimize band

spreading. Deviation from Waters specified tubing could result

in deterioration of chromatographic performance. Figure 5

shows the influence of tubing inner diameter. Using larger

tubing causes excessive peak broadening, lower sensitivity,

and loss in resolution.

Diluted/Distor ted Sample Band

0.005 inches

0.020 inches

0.040 inches

Figure 5. Effect of Connecting Tubing on System.

IV. TROUBLESHOOTING

Changes in retention time, resolution or backpressure are

often due to column contamination. See the Column Cleaning,

Regeneration and Storage section of the care and use manual.

Information on column troubleshooting problems may be

found in HPLC Column Theory, Technology and Practice, U.D.

Neue, (Wiley-VCH, 1997); Waters HPLC Troubleshooting Guide

(Literature Code # 720000181EN); or by visiting www.waters.com

V. COLUMN CLEANING, REGENERATION

AND STORAGE

Assuming that there is no damage to the column bed, changes

in peak shape, peak splitting, shoulders on the peak, shifts in

retention, change in resolution or increasing backpressure

may indicate contamination of the column. Flushing with high

concentrations of organic solvent, taking care not to precipitate

buffers, is usually sufficient to remove the contaminant. If the

flushing procedure does not solve the problem, purge the column

using the following cleaning and regeneration procedures.

a. Cleaning and Regeneration

Use a cleaning routine that matches the properties of the samples

and/or what you believe is contaminating the column. The

columns are stable using a wide range of solvents to improve the

dissolution of the contaminant. Before beginning any cleaning

procedure it is best to isolate the column from downstream

For example, if you were to select a three-column bank using

45Е, 200Е and 450Å columns and require that DMF to be used

as the mobile-phase solvent, you would be limited to a maximum

flow rate of 1.0 mL/min. In this case, DMF has a solvent viscosity

of 0.92 cP at 25 °C. Under these conditions the 450Å column

limits the flow to 1.0 mL/min, even though the other columns

can support a higher flow.

Note: When connecting multiple columns in series, the maximum flow rate may

not be achievable due to pressure limitations of the instrumentation. Please

refer to the system's owner manual for more information.

Table 3. Recommended Mobile Phase

Flow Rate for a Single ACQUITY APC Column

Pore Size

(Å)

Maximum Flow

Rate at Solvent

Viscosity < 0.6 cP

Maximum Flow

Rate at Solvent

Viscosity > 0.6 cP

45

1.8 mL/min

1.1 mL/min

125

2.0 mL/min

1.6 mL/min

200

2.0 mL/min

1.4 mL/min

450

1.7 mL/min

1.0 mL/min

900

0.90 mL/min

0.60 mL/min

**References:

1. Reid, R.C., Prausnitz, J.M., Poling, B.E. The Properties of Gases and Liquids,

4th Edition, McGraw Hill, 1987, Table 9-8.

2. http://www.wolframalpha.com

3. Yang, J. Chem Eng Data (2008), 53, 1639-1642.