Memmert INCO 246/246 med CO2 Incubators (Generation 2003) User Manual

Page 38

38

Operation and control

To be on the safe side, a freshly filled CO

2

gas bottle should always be used. So if the gas in

bottle 1 is used up, you connect the opened bottle to IN1 and the newly filled bottle as a

reserve bottle to IN2.

The hose connection system used by Memmert shuts off automatically if a connection hose is

pulled off. You should still always close the stop valve on the gas bottle if a bottle is empty or

not connected.

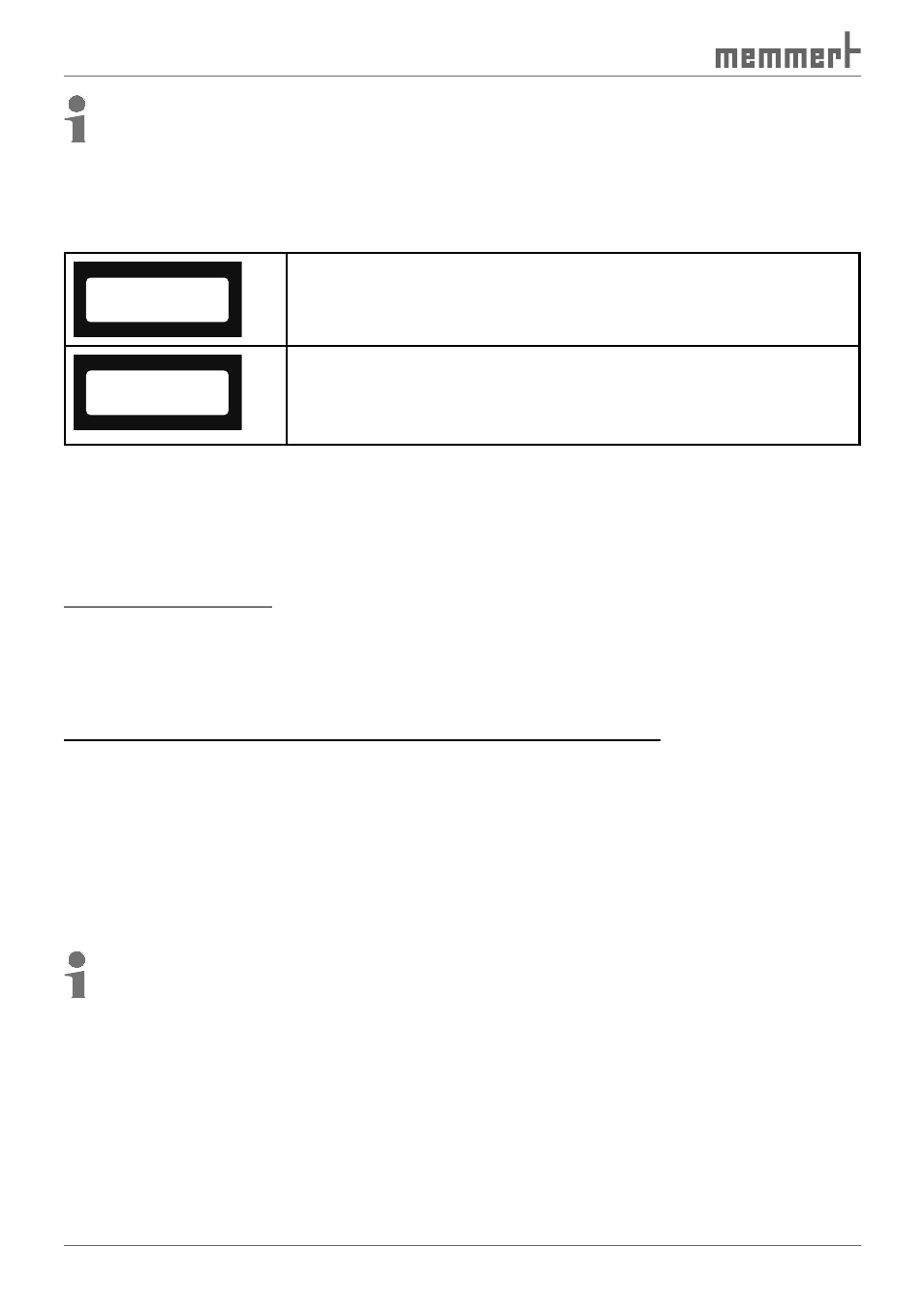

IN 1

lights up when gas bottle 1 is active. If gas bottle 1 is empty,

there is an automatic switch-over to the reserve bottle.

IN 2

lights up after the switch-over to gas bottle 2 (reserve bottle).

Switching over to the reserve bottle is marked by a short re-

peated acoustic signal (about 3 seconds long) (the default after

switching on is gas bottle 1).

In the following cases, a switch-over is made from reserve bottle 2 back to the main supply

bottle 1:

►

if the reserve bottle is empty

►

each time after the appliance is switched on

►

after every change of the CO

2

setpoint

Humidity limit control

A humidity limit control prevents the formation of condensation water in the chamber and

at the same time ensures that the setpoint humidity is quickly reached, with short recovery

times.

The maximum achievable humidity can be adjusted in the standard model from 88 to 97% rh.

Active humidity control (only for models with humidity module)

The active humidity control guarantees that setpoint humidity is quickly reached, without the

use of water trays.

In the heating up phase, the humidity control is initially deactivated. Approx. 5 minutes after

the setpoint temperature is reached, the humidification and dehumidification control starts

working. The setpoint can be set from 40 to 97 % rh. The humidity setpoint can also be ad-

justed during the transient state. For humidification, water is let into the chamber via a dosing

pump. To avoid the formation of germs, the steam is first heated to approx. 140 °C. Dehumid-

ifcation takes place through the supply of dry air via a sterile filter.

If no humidity is required in the chamber, the humidity control can be deactivated by

setting it to OFF.