Operation and control, 1 operating personnel, 2 opening the door – Memmert INCO 246/246 med CO2 Incubators (Generation 2003) User Manual

Page 27: 3 loading the incubator

27

Operation and control

5.

Operation and control

5.1

Operating personnel

The incubator may only be operated by persons who are of legal age and have received in-

structions for the incubator. Personnel who are to be trained, instructed or who are undergo-

ing general training may only be active on the incubator under the continuous supervision of

an experienced person.

5.2

Opening the door

►

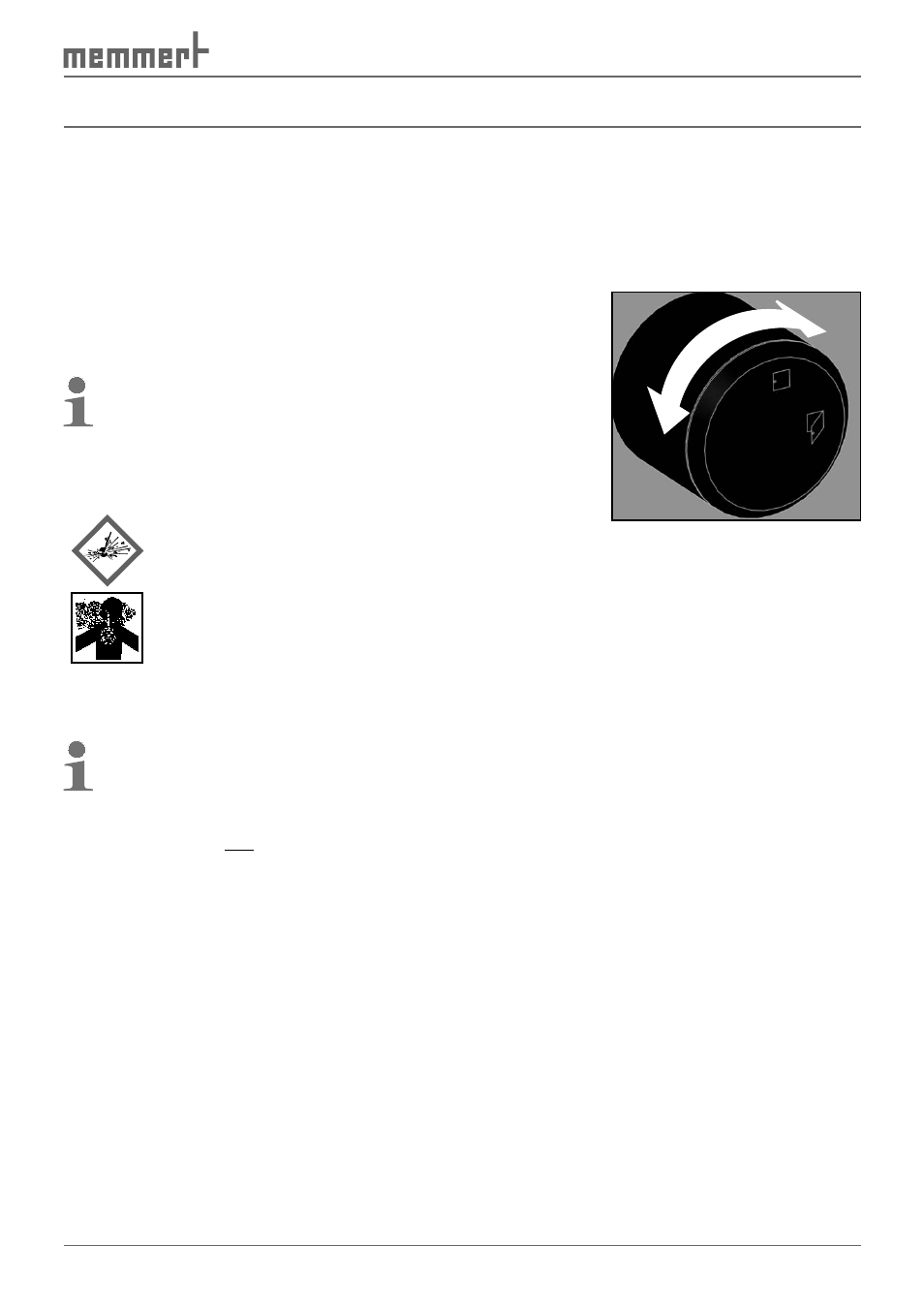

To open the door, turn handle to the right ( Fig. 14 ).

►

To close, turn door handle to the left.

When the door is opened, the CO

2

supply is automati-

cally interrupted. If the heated outer door is left open for

any length of time, condensation may form on the glass

door.

5.3

Loading the incubator

Warning!

When loading the chamber with an

unsuitable load, poisonous or explosive

vapours or gases may be produced. This

could cause the chamber to explode, and people could be badly in-

jured or poisoned. The chamber may only be loaded with materials/

test objects which do not form any toxic or explosive vapours when

heated up, and which cannot ignite. If there is any doubt as to the

composition of materials, they must not be loaded into the incuba-

tor.

Caution:

Check the chamber load for chemical compatibility with the materials of the incubator

(see page 13 ), since considerable damage could otherwise occur to the chamber load,

the appliance or the surroundings.

The incubators are not explosion-proof (they do not comply with workplace health & safety

regulation VBG 24) and are therefore not suitable for drying, vaporising and branding paints

or similar materials, the solvents of which could form an explosive mixture when combined

with air. Potentially explosive gas-air mixtures must not be produced, either in the interior of

the chamber or in the direct vicinity of the appliance.

Heavy dust production or aggressive vapours in the chamber or in the vicinity of the appli-

ance could lead to sedimentation in the chamber interior and as a consequence, could result

in short circuits or damage to electrical parts. For this reason, sufficient measures should be

taken to prevent large clouds of dust or aggressive vapours from developing.

The chamber must not be loaded too tightly, so that proper air circulation in the working

chamber is guaranteed. Do not place any of the chamber load on the floor, touching the side

walls or right below the ceiling (heating ribs) of the working chamber. To guarantee an opti-

mal air circulation, push in the sliding shelves so that the gaps between the door, sliding shelf

and rear wall of the chamber are roughly the same size.

open

close

Fig. 14

Opening and

closing the door