3 process data telegram, 4 assignment of the user data to variables, Process data telegram – Lenze DDS System bus CAN for PLC User Manual

Page 91: Assignment of the user data to variables, System bus (can) for lenze plc devices, Can system blocks

System bus (CAN) for Lenze PLC devices

CAN system blocks

7.1

CAN1_IO (node number: 31) − 9300 Servo PLC

7−3

L

PLC−Systembus EN 2.0

7.1.3

Process data telegram

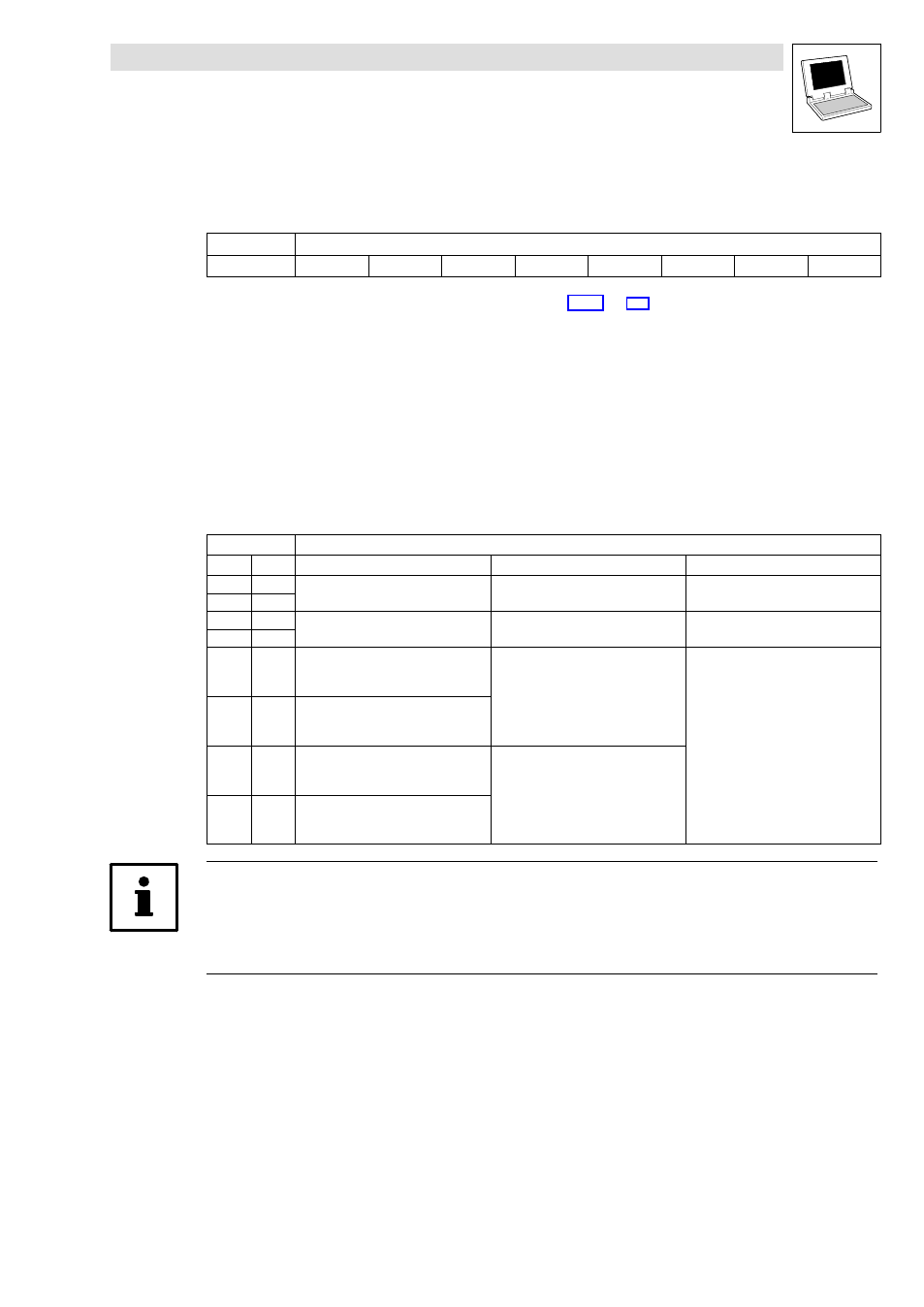

The process data telegram consists of an identifier and 8 bytes of user data.

11bit

8 bytes user data

Identifier

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

Information on the identifier can be found in chapter 2.4.1.

(

7.1.4

Assignment of the user data to variables

Several variables of different data types are assigned to the user data to be transmitted and received.

Thus, the data in the PLC program can be optionally interpreted as:

·

binary information (1 bit)

·

status word/quasi−analog value (16 bit)

·

angle information (32 bit)

Variables for user data to be transmitted

User data

Assigned variables

Byte

Bit

Variable (1 bit)

Variable (16 bit)

Variable (32 bit)

1

0...7

CAN1_wDctrlStat

2

0...7

3

0...7

CAN1_nOutW1_a

4

0...7

5

0

...

7

CAN1_bFDO0_b

...

CAN1_bFDO7_b

CAN1_nOutW2_a

CAN1_dnOutD1_p

6

0

...

7

CAN1_bFDO8_b

...

CAN1_bFDO15_b

7

0

...

7

CAN1_bFDO16_b

...

CAN1_bFDO23_b

CAN1_nOutW3_a

8

0

...

7

CAN1_bFDO24_b

...

CAN1_bFDO31_b

Note!

Avoid simultaneous overwriting via different variable types to ensure data consistency.

For instance, if you want to write bytes 5 and 6, only use the variable CAN1_dnOutD1_p,

CAN1_nOutW2_a, or only the variables CAN1_bFDO0_b ... CAN1_bFDO15_b for this purpose!