13 diagnostics, 1 operating status of the can interface, Operating status of the can interface – Lenze DDS System bus CAN for PLC User Manual

Page 47: System bus (can) for lenze plc devices, Can" system bus interface configuration

System bus (CAN) for Lenze PLC devices

"CAN" system bus interface configuration

3−13

l

PLC−Systembus EN 2.0

3.13

Diagnostics

The following codes can be used for diagnostics purposes:

Code

Information displayed

Information

C0359

Operating status of the system bus

Chapter 3.13.1

^ 3−13

C0360

Number of the telegrams sent and received

Chapter 3.13.2

^ 3−14

C0361

Bus load (in %)

Chapter 3.13.3

^ 3−15

·

Settings cannot be carried out via these codes.

3.13.1

Operating status of the CAN interface

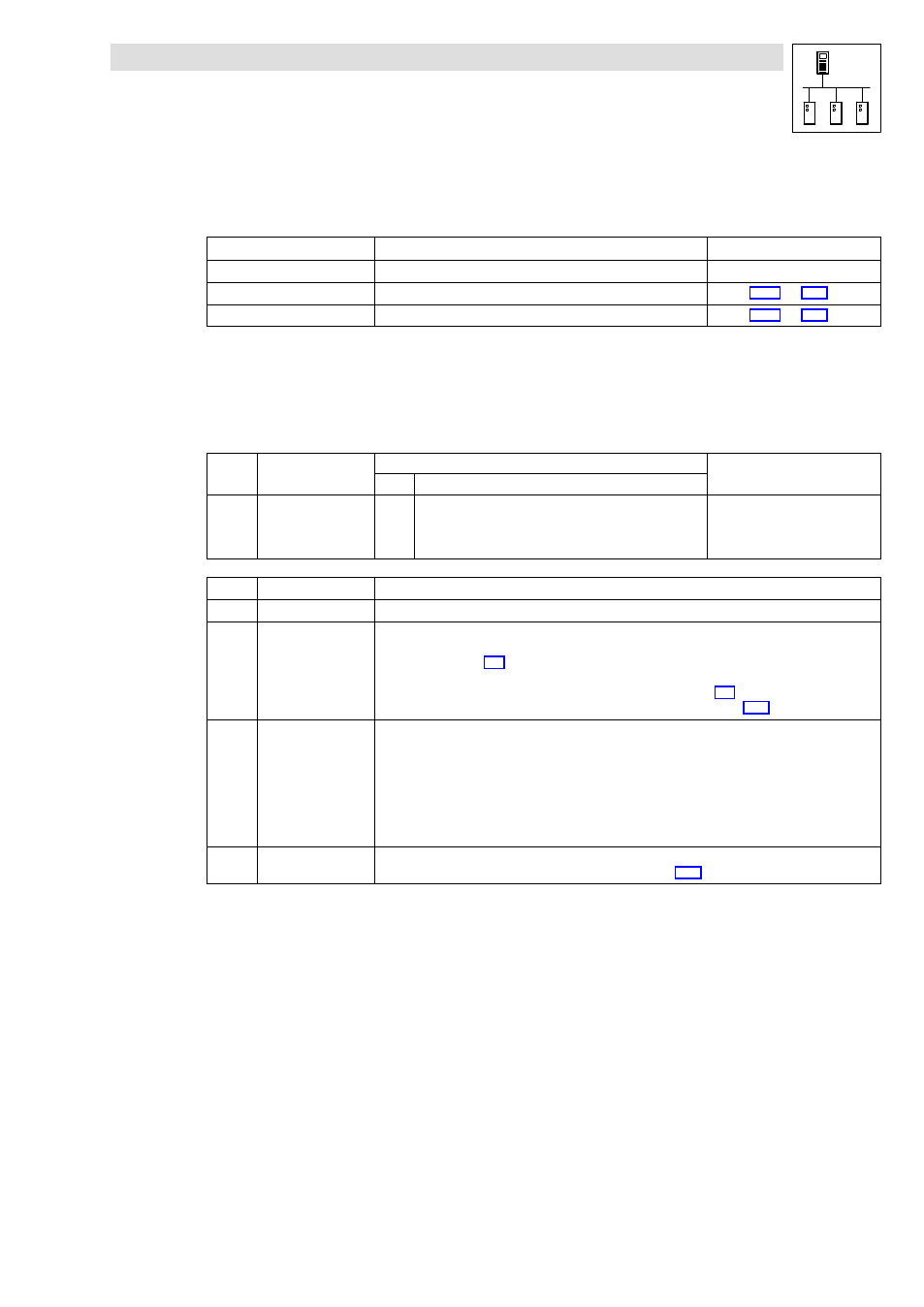

Via C0359 you can have the operating status of the system bus displayed:

Code

LCD

Possible settings

Information

Lenze

Selection

C0359 CAN state

g

0

Operational

1

Pre−operational

2

Warning

3

Bus off

System bus status

C0359

Operating status

Information

0

Operational

The system bus is fully functional. The PLC can transmit and receive parameter and process data.

1

Pre−operational

The PLC can transmit and receive parameter data. Process data, however, are ignored.

A status change from Pre−operational to Operational can be effected by:

·

the CAN master

^ 3−2

·

a reset node

– via C0358, if the PLC has been configured as a "quasi" master.

^ 3−8

– via the binary input signal "reset node" at the CAN_Management SB

^ 7−20

2

Warning

The PLC has received faulty telegrams and is only involved in the system bus passively, i. e. no data can be

sent from the PLC anymore.

Possible causes:

·

Missing bus termination

·

Non−sufficient shielding

·

Differences in potential with regard to the earth connection of the control electronics

·

Bus load too high

·

PLC is not connected to the system bus.

3

Bus−off

The PLC has disconnected from the system bus due to too many faultily received telegrams.

·

The response to this status can be configured via C0595.

^ 3−11