ERICO 3000 ERITECH SYSTEM User Manual

Page 39

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

37

www.erico.com

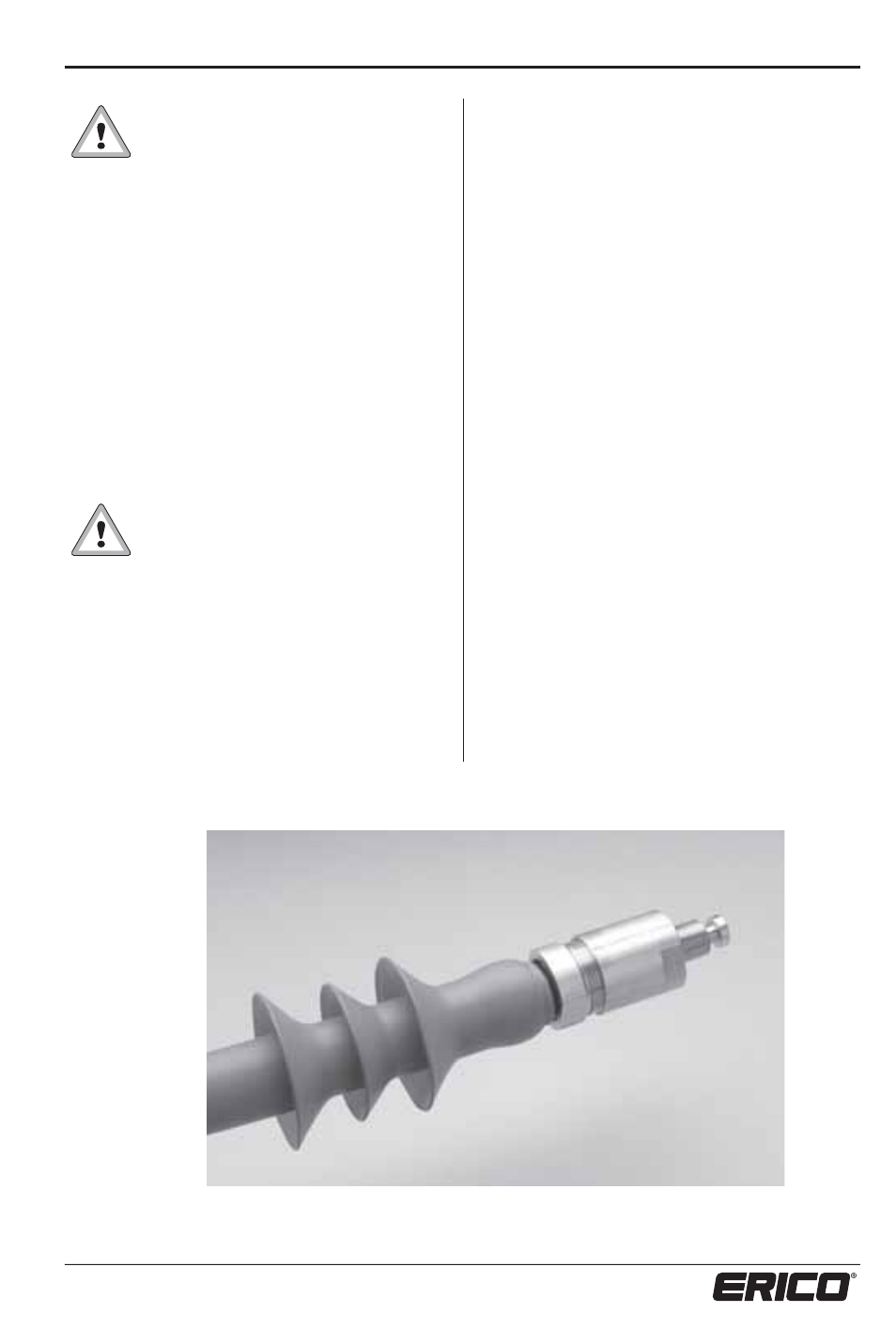

Photo 11: Installed compression coupling.

The coupling must be tightened

using spanners / wrenches, as

tightning by hands will not be

adequate.

22. Using the roll of silicone tape (grey),

overwrap half layers from 20 mm (

3

⁄

4

in.) over

the end of the coldshrink to 30 mm (1

1

⁄

8

in.)

over the coupling so that it covers the joint

between the main coupling and compression

nut, (refer to figure 24 on page 39).

Wrap with moderate tension (10 to 100%

stretch). Apply one final layer with no stretch.

Press down, to avoid the end lifting before

fusion of the tape takes place.

The finished termination must be

protected against any abrasion

and sharp edges during transport

or installation, as the coldshrink

tubes are susceptible to ripping or

tearing if nicked or scuffed.

23. The structure bonding braid MUST be

electrically connected via a 6 mm

2

(8 AWG)

length of insulated copper cable to the

specified conductive structural point, as

described in the ERITECH

®

SYSTEM 3000

Installation, Operation & Maintenance

Manual.

Connecting the ERITECH

®

DYNASPHERE

24. Feed the downconductor (and

structure bonding cable) through the

FRP mast so that the entire termination

is protruding from the top of the mast.

Remove the lock screw in the base of the

ERITECH

®

DYNASPHERE terminal, then

screw the terminal all the way onto the

termination coupling thread. Replace the

lock screw back into position so that it

locks the thread into place and will stop

the terminal from unscrewing.

25. Carefully pull the downconductor

(and structure bonding cable) back down

through the FRP mast so that the terminal

base sits correctly in the top of the mast.

Twist the FRP mast at least one complete

turn at the base of the terminal to remove

any stress on the termination sheds

(flanges) and to seat the terminal correctly.