ERICO SBC Series, Beam Clamp, 3/8" and M10 User Manual

Sbc series, Beam clamp, 3/8" and m10

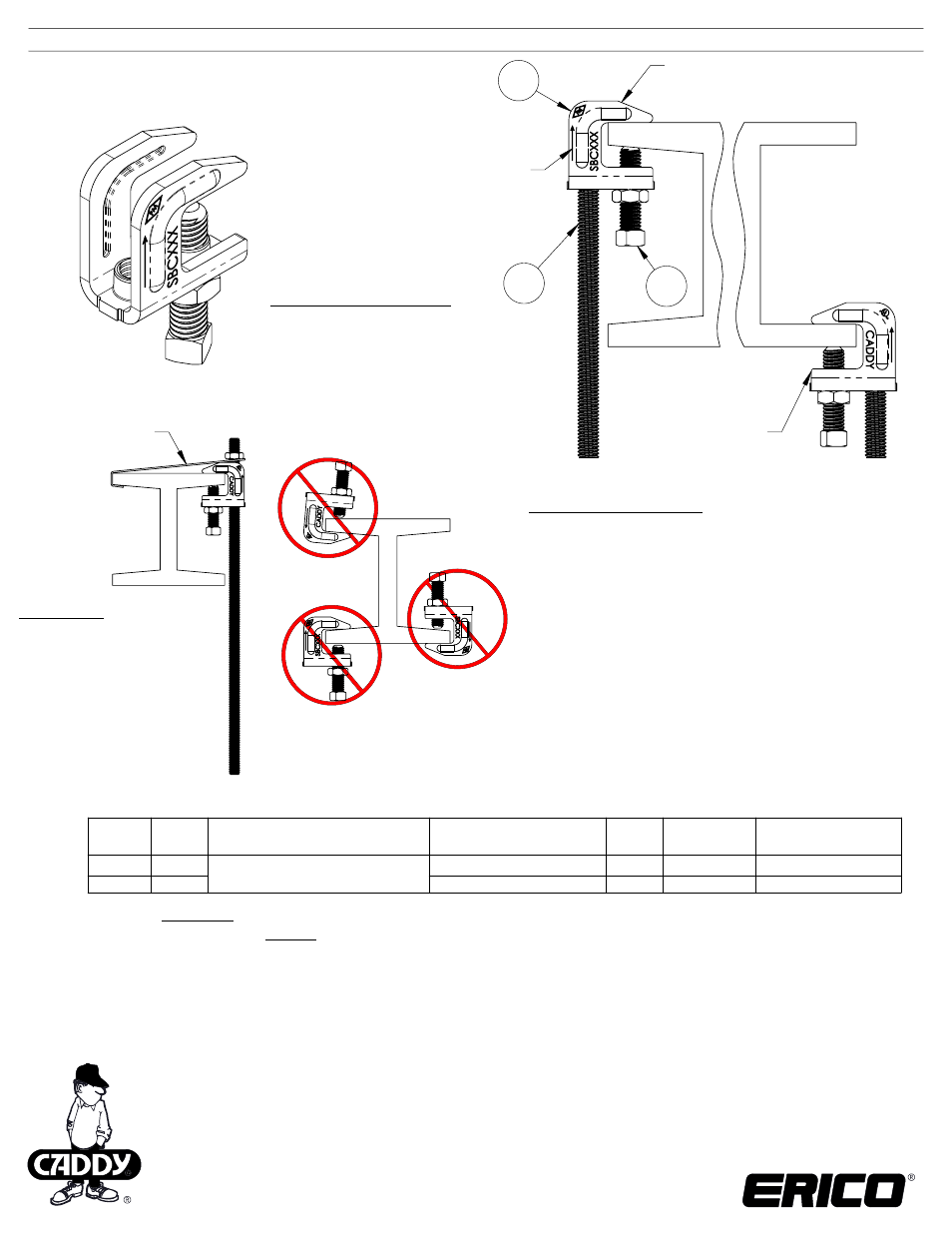

Figure 1

Figure 2

1

On tapered flange, clamp is

to be mounted in top position only.

2

On parallel flange,

clamp may be

top or bottom

mounted in this

orientation.

3

ARROW ALWAYS

POINTING UP

Figure 3

Incorrect mounting

configurations.

retaining strap

(Sold separately)

Allows structural

attachment to metal

beams, bar joist,

channel, or angle iron in

top mount position only

unless used on a parallel

flange.

Installation Instructions:

Position Clamp on top flange of beam per

1.

Figure 2.

Tighten screw. Set screw must be tightened to

2.

sloped side of I-beam, channel or angle iron

flange and torqued to the value specified in the

chart below. Tighten set screw jam nut.

Insert threaded rod (not included) into

3.

threaded hole and adjust to desired height.

Clamp must not be secured in reverse position.

4.

See figure 3 for incorrect mounting positions.

Note: Threaded rod is not included.

Installation:

Install beam clamp

1.

Place strap over

2.

loaded rod

Secure with nut

3.

Use hammer to bend

4.

strap around beam

Part

Number Model

Description

Max. Pipe Dia. Supported by

Clamp & Threaded Rod

Rod Size

Min. Set

Screw

Torque

Maximum

Recommended Load

SBC037

SBC

Top Mount Beam Clamp to secure

threaded rod to structure.

4 inches

3/8 in

60 in-lbs

500 lbs

SBCM10

SBC

4 inches

M10

60 in-lbs

500 lbs

TECHNICAL SUPPORT:

www.erico.com

CFS481_E

INSTRUCTION SHEET

1 OF 1

© 2012, 2013, 2014 ERICO International

Corporation.

SBC Series

Beam Clamp, 3/8" and M10

WARNING:

ERICO products shall be installed and used only as indicated in ERICO product instruction sheets and training materials. Instruction sheets are available at

1.

www.erico.com and from your ERICO customer service representative.

ERICO products must never be used for a purpose other than the purpose for which they were designed or in a manner that exceeds specified load ratings.

2.

All instructions must be completely followed to ensure proper and safe installation and performance.

3.

Improper installation, misuse, misapplication or other failure to completely follow ERICO's instructions and warnings may cause product malfunction, property

4.

damage, serious bodily injury and death.

Products that are manufactured using spring steel components shall be used only in a non-corrosive indoor environment.

5.

All pipe supports, hangers, intermediate components and structural attachments must ONLY be used as described herein and are NEVER to be used for any

6.

other purpose.

NOTE: All load ratings are for static conditions and do not account for dynamic loading such as wind, water or seismic loads, unless otherwise noted.

The customer is responsible for:

a. Conformance to all governing codes.

b. The integrity of structures to which the products are attached, including their capability of safely accepting the loads imposed, as evaluated by a qualified

engineer.

c. Using appropriate industry standard hardware as noted above.

SAFETY INSTRUCTIONS:

All governing codes and regulations and those required by the job site must be observed.

Always use appropriate safety equipment such as eye protection, hard hat, and gloves as appropriate to the application.

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.